Brakes are undoubtedly the largest volume repair in most independent repair shops today. When performed correctly, they can be a very profitable service. Depending on how the vehicle is driven, proper brake repairs should last anywhere from 40,000 to 60,000-plus miles, with some exceptions of course, such as taxi cabs and mail delivery vehicles, etc.

Pads and rotors are the foundation of any ABS, stability or traction control system. Without the right friction levels or rotor surface, these complex systems will not operate properly. This is why extra attention should be paid to any late-model vehicle when performing basic brake repairs.

As vehicle weight became a great concern due to increased fuel mileage, manufacturers began designing brake components lighter and with the composite rotors cast with two alloys. These lighter components on today’s modern vehicles tend not to absorb vibrations as well. These new designs are even more prone to stacked tolerances in the knuckle-to-bearing and the hub-to-rotor assemblies. Rust and corrosion have increased the chances of lateral run-out and thickness variations as well.

Lateral brake run-out means the rotor wobbles from side to side when spinning. Lateral run-out will cause the rotor to contact the brake pads, knocking them back as the high spot of the run-out contacts the pads, allowing more pedal travel before the pad’s surface makes contact with the rotor. Rotor run-out will lead to thickness variations, inevitably leading to brake pulsations.

Rotor and hub run-out must be less than 0.002” to minimize lateral run-out and thickness variation. In comparison, a normal piece of copy paper is 0.004” thick, so you can see that there’s not much room for error.

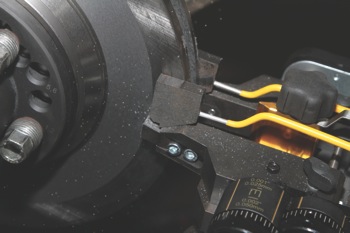

Whether reusing the existing or replacing with new rotors, they must be matched to the hub due to run-out variations between the hub and rotor utilizing an on-vehicle brake lathe, see Figure 1. Not performing the correct procedures can cause brake pulsations, inevitably leading to dissatisfied customers and comebacks.

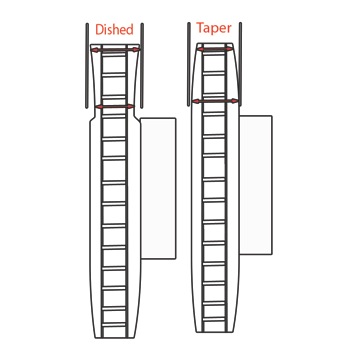

Rotors need to be serviced during every brake pad replacement and, depending on geographical location (especially the Rust Belt), the rotors need to be serviced due to rust alone. In the past, a technician would remove the rotors and replace them or resurface them to help correct lateral run-out, parallelism, tapering, dishing, etc. on a bench lathe and then reassemble them back on the vehicle.

Bench lathes can be of some concern due to conditions mentioned previously (hub-to-rotor variations). Resurfacing on a bench lathe true’s the rotor to the lathe, not to the vehicle or hub. Prior to using existing rotors, a micrometer should be used to check for thickness to ensure the  rotor is worthy of being resurfaced. If the rotor thickness is acceptable, a dial indicator should be used to check for lateral run-out, dishing or taper, see Figure 2. Advanced on-vehicle brake lathes have the ability to measure rotor thickness electronically on a digital read out, and also measure the amount of cutting depth adjustments made digitally.

rotor is worthy of being resurfaced. If the rotor thickness is acceptable, a dial indicator should be used to check for lateral run-out, dishing or taper, see Figure 2. Advanced on-vehicle brake lathes have the ability to measure rotor thickness electronically on a digital read out, and also measure the amount of cutting depth adjustments made digitally.

So, the questions remain to be asked: are the existing rotors reusable or will they need to be  replaced? Several things need to be observed when deciding to reuse the existing rotors. First, is the rotor worthy of being resurfaced? We’ve probably all seen the split vented rotor, see Figure 3, this is due to extremely rusted cooling fins. The fins hold the inside of the rotor to the face. Discard the rotor if you find thinning cooling fins or extreme rust buildup. For non-vented as well as vented rotors, check to see if they have been overheated. This can cause small or large cracks, causing lateral run-out and will deem the rotor unusable, see Figure 4. Specifications provided from the manufacturer typically give a disc diameter, maximum lateral run-out, parallelism, allowable scoring, etc.

replaced? Several things need to be observed when deciding to reuse the existing rotors. First, is the rotor worthy of being resurfaced? We’ve probably all seen the split vented rotor, see Figure 3, this is due to extremely rusted cooling fins. The fins hold the inside of the rotor to the face. Discard the rotor if you find thinning cooling fins or extreme rust buildup. For non-vented as well as vented rotors, check to see if they have been overheated. This can cause small or large cracks, causing lateral run-out and will deem the rotor unusable, see Figure 4. Specifications provided from the manufacturer typically give a disc diameter, maximum lateral run-out, parallelism, allowable scoring, etc.

Important: Keep in mind to discard the rotors if they are below minimum refinish thickness or discard thickness to prevent an unsafe brake system. When reusing the existing rotors, we obviously know to resurface them, as pad slapping is a thing of the past, as I truly hope! On-vehicle brake lathes are required by most vehicle manufacturers when performing brake repairs. Always check manufacturers’ specification when servicing vehicles.

Similar conditions exist when installing new rotors on the vehicle, such as hub-to-rotor matching. When rotors are manufactured, they are trued to a lathe, not the vehicle hub. Adding to that, another issue can be shipping and storing rotors that can affect lateral run-out.

Rotor costs vary depending upon rotor quality, manufacturer, vehicle and supplier, as well as the material used to design the rotor. A parts supplier may give you two prices, one for its average store line and another for a premium rotor. For example, 2006 Impala rotors from one part supplier had two rotors available, the premium rotor was twice the price of the store line rotor. While the premium rotor may cool better and not rust as quickly from “lot rot,” this does not alleviate the need to true or match it to the hub.

Hub-to-rotor matching is a necessity to ensure a quality brake repair, and purchasing the highest quality rotor won’t eliminate this concern. In other words, even though two vehicles are the same year, make and model, they may have completely different stacked tolerances and lateral run-out with the same rotor.

In some cases, just removing the wheels can disturb rust between the rotor and hub. Prior to matching rotors, whether reusing or replacing them, clean the hub and rotor surfaces. Rust and corrosion can build up on the surfaces between the hub and rotor. Removing the wheel can loosen corrosion, constantly changing contact areas. Cleaning the corrosion from the wheel, rotor and hub is also important to prevent “wheel offs.” Once the wheel/rotor is loosened or removed, the corrosion loosens, and, if not removed, the wheel may appear as if it has been correctly torqued, however, once the vehicle is driven, the corrosion shifts, loosening the wheel.

corrosion loosens, and, if not removed, the wheel may appear as if it has been correctly torqued, however, once the vehicle is driven, the corrosion shifts, loosening the wheel.

Most “wheel offs” have been related to corrosion on surfaces of the hub, rotor and wheels, especially with aluminum wheels. Figure 5 shows an aluminum wheel partially cleaned. If it were to be installed without a thorough cleaning, it would most likely cause damage. Clean surfaces also provide proper heat transfer from the brake components, allowing proper cooling. Using a good stainless-steel wire brush makes a big difference. I have found “caliper brushes” work well for this, and they are thin enough to get between the studs and hub center, see Figure 6. There  are also the surface cleaning discs made to go over the studs to help remove corrosion, see Figure 7.

are also the surface cleaning discs made to go over the studs to help remove corrosion, see Figure 7.

Resurfacing the rotors on the vehicle is a must when reusing or replacing rotors, see Figure 8. Typically, a pulsation is not going to be felt by the technician when burnishing the brakes or a  simple road test. Also, pulsations will increase over time and are most often felt on high-speed slowdowns or stops, such as highway off ramps.

simple road test. Also, pulsations will increase over time and are most often felt on high-speed slowdowns or stops, such as highway off ramps.

Pulsations can take some time for the vehicle occupants to feel and they may continue to drive the vehicle for months after, increasing the pulsation until it is unbearable. The customer now returns with a brake pulsation concern or worse — they don’t return to your shop at all. They may have the vehicle repaired elsewhere, not giving you the opportunity to correct the concern. So, eliminating any chance of a pulsation or noise concern the first time will increase customer satisfaction.

In Figure 9, one 0.008” cut was made (0.004” per side) on a new installed rotor; you can see that 25% of the rotor was missed with the first pass of the lathe. This new rotor was matched to the vehicle hub to run a true centerline and help eliminate any brake pulsations. Just think if this were not matched to the hub. How would the brakes wear, would the pedal feel smooth? Now, I know what you’re thinking, how is this going to improve my brake repairs? I haven’t had many issues. I thought the same thing until I began matching rotors to the hub. Instantly, while road-testing the first vehicle, it seemed as if braking was effortless and smoother than I ever felt when applying the pedal. Once you try this, I’m sure you’ll agree and so will your customers.

After resurfacing the rotors, be sure to wash with warm, soapy water to prevent brake noise. I know it’s an extra step and brake clean works just as well — so you think! Try this: resurface a rotor, blast it with brake clean and wipe with a clean paper towel, repeat again and one more time. You continue to remove particles of metal from the rotor. Now try this with soapy water and you’ll understand why it’s necessary to avoid using brake clean for this procedure. Using soapy water in a spray bottle and rinsing it off works very well.

Using on-vehicle brake lathes for today’s vehicles is a must whether you’re reusing or replacing the rotors. As vehicle operators drive faster (speed limits…who obeys them?!) and vehicles are equipped with lighter-weight components, vibrations increase from the smallest amount of lateral run-out. Taking several extra steps will help prevent brake repair comebacks, assuring customers are satisfied when braking for thousands of miles.