Anyone who works on brakes should be familiar with basic hydraulics and the various components that make up the hydraulic portion of the brake system. So if you’re not as familiar with this subject as you should be, keep reading and we’ll refresh your memory.

We’ll start at the heart of the system, which is the master cylinder. It converts the force exerted on the brake pedal by the vehicle’s driver into hydraulic pressure to apply the brakes. Depressing the brake pedal moves a push rod in the master cylinder. Mounted on the push rod are a pair of pistons (primary and secondary) in tandem (one after the other) to push against the fluid in the master cylinder bore. This creates pressure which displaces fluid because it’s incompressible. As fluid is pushed from the master cylinder, it exerts pressure through the brake lines to apply each of the brakes.

When the brake pedal is released, the spring-loaded piston assembly in the master cylinder returns to its rest position. The fluid that was displaced by the pistons is pushed back to the master cylinder as the disc brake pads kick out away from the rotors, and the springs inside the drums retract the brake shoes. The fluid returns to the fluid reservoir through the “compensating ports,” which are small openings between the master cylinder bore and fluid reservoir just ahead of each of the pistons.

Master cylinders are divided into two separate hydraulic circuits, with each having its own fluid reservoir and piston. It’s a safety requirement so that if a leak occurs in one circuit, it won’t affect the other circuit, leaving at least two brakes operational to stop the vehicle. With most rear-wheel-drive (RWD) vehicles, the hydraulic system is divided front to rear with one circuit for the front brakes and a second circuit for the rear brakes. On many front-wheel- drive (FWD) cars, the brake system is split diagonally. The left front and right rear brakes share one circuit, while the right front and left rear brakes share the other.

The most common problems that occur in the master cylinder are wear in the piston bore and piston seal failure. The classic symptom of a failing master cylinder is a brake pedal that slowly sinks while pressure is held against the pedal. The cure is to replace the master cylinder.

PROPORTIONING VALVES & BRAKE BALANCE

To reduce hydraulic pressure to the rear brakes so the rear brakes don’t lock up when the brakes are applied, a “proportioning valve” is required. This valve helps compensate for the differences in weight distribution front-to-rear as well as the forward weight shift that occurs when the brakes are applied.

What we’re really talking about here is “brake balance” or “brake bias,” which is the difference in the amount of hydraulic pressure channeled to the front and rear brakes. The front brakes on most rear-wheel-drive vehicles normally handle about 60-70 percent of the brake load. But on front-wheel-drive cars and minivans, as well as RWD and 4WD pickups and SUVs, the percentage handled by the front brakes can be as much as 90 percent of the load.

Consequently, the front brakes need a higher percentage of the total hydraulic force that’s applied to keep all four brakes properly balanced.

Consequently, the front brakes need a higher percentage of the total hydraulic force that’s applied to keep all four brakes properly balanced.

If the front-to-rear brake force isn’t balanced correctly by the proportioning valve, the rear brakes will receive too much brake force, causing them to lock up and skid when the brakes are applied. The other reason for using a proportioning valve to reduce hydraulic pressure to the rear brakes has to do with the design of the brakes themselves. When hydraulic pressure is applied to the wheel cylinder inside a drum brake, the shoes are pushed outward against the drum. When the shoes make contact, the rotation of the drum tries to drag them along. But since the shoes are anchored in place, the drum pulls the shoes up tighter only against itself. Because of this, drum brakes that are “self-energizing” require little additional pedal effort once the brakes are applied. Disc brakes, on the other hand, are not self-energizing. It takes increased pedal effort to squeeze the pads against the rotor.

Some vehicles have “load sensing” proportioning valves that change rear brake metering to compensate for changes in vehicle loading and weight shifts that occur during braking. This type of proportioning valve has an adjustable linkage that connects to the rear suspension or axle. As the vehicle is loaded, ride height decreases and pressure to the rear brakes is increased. This type of proportioning valve can be found on many minivans, pickups and even some passenger cars.

Load sensing proportioning valves usually are adjustable, and must be adjusted correctly if they are to properly balance the rear brakes to the vehicle’s load. The valve linkage is adjusted with the suspension at its normal height (wheels on the ground) and the vehicle unloaded. The adjustment bracket or linkage is then adjusted according to the vehicle manufacturer’s instructions, which typically involves adjusting the linkage to a certain position or height.

Load-sensing proportioning valves are also calibrated to work with stock springs. Any suspension modifications that increase the load-carrying capability (installing helper springs, or overload or air-assist shocks, for example) may adversely affect the operation of this type of proportioning valve. Modifications that make the suspension stiffer reduce the amount of deflection in the suspension when the vehicle is loaded, which prevents the proportioning valve from increasing rear brake effort as much as it normally would. A defective proportioning valve, or one that is not properly adjusted, can also upset brake balance. If the rear brakes on a vehicle seem to be overly aggressive (too much pressure to the rear brakes), or the vehicle seems to take too long to stop (not enough pressure to the rear brakes), the problem may be a bad proportioning valve. Proportioning valves can be tested by installing a pair of hydraulic gauges (one on each side of the valve) to see if the valve reduces pressure as it should.

On some late-model vehicles, the mechanical proportioning valve has been replaced by “electronic” brake proportioning through the ABS system. By sensing wheel speeds, the ABS system reduces pressure to the rear brakes as needed when the brakes are applied.

METERING VALVE

METERING VALVE

Another device called a “metering” or “hold-off” valve is used in many vehicles that have front disc brakes and rear drum brakes to compensate for physical differences between the two different types of brakes. The metering valve holds off or delays the application of hydraulic pressure to the front disc brakes until the rear drums start to work. This is necessary because disc brakes don’t have return springs and, consequently, start to apply as soon as hydraulic pressure reaches the calipers. But the shoes inside the rear drum brakes have to first overcome the resistance of the return springs before they engage the drum. The metering valve (or valves) usually is located in the hydraulic lines to the front brakes.

PRESSURE DIFFERENTIAL VALVE

Located between the front and rear (or diagonally split) brake lines in most brake systems is a “pressure differential valve.” This valve contains a switch that illuminates the brake warning light to warn the driver in case either side of the brake system loses pressure. The valve has a piston that remains in a neutral position as long as pressure on both sides of the hydraulic system are equal. A loss of fluid on either side causes the piston to slide to one side when the brakes are applied, which completes the electrical circuit to illuminate the brake warning light. The valve is self-centering on most applications, but must be reset on others if a problem has occurred. On some applications, the pressure differential valve, proportioning and/or metering valves are combined into one unit.

BRAKE LINES & HOSE

The arteries of the brake system are the steel lines and flexible rubber hose that route hydraulic pressure to each brake when the driver steps on the brake pedal. The lines and hose must withstand pressures that can range from a few hundred pounds per square inch up to almost 2,000 psi! If a line or hose can’t take the pressure and blows, all braking ability in the affected brake circuit will be lost.

A slow leak in a brake line or hose is almost as bad as a sudden failure because, over time, enough fluid may be lost to allow air to enter the hydraulic system. Air in the fluid is bad because air is compressible. This increases the amount of pedal travel that’s necessary to apply the brakes, and may increase it to the point where the pedal hits the floor before the brakes apply.

The first indication of a leak in a brake line or hose may be a low fluid level in the master cylinder reservoir. Other clues may include wet spots on the driveway, dampness on the back of a drum brake, or a brake warning light that comes on. If a leak is suspected, the entire brake system should be inspected to find the leak.

The most likely leak points are the brake calipers, wheel cylinders and rubber brake hoses, though steel lines can also rust through and leak. Fluid can sometimes be pulled into the engine through a leak in the power brake vacuum booster. If there’s any fluid inside the brake booster vacuum hose, the brake booster needs to be replaced. Rubber brake hoses also need to be inspected for age cracks, bulges, swelling or other damage that would indicate a need for replacement. Rubber hoses have an expansion-resistant inner lining that should not give under pressure. If the inner liner leaks, fluid will force its way under the outer liner causing a bubble or blister to appear when the brakes are applied.

Although it doesn’t happen very often, sometimes internal damage or deterioration in a rubber hose allows a small flap of material to lift up and plug the line. This prevents brake pressure from reaching the wheel, causing a brake pull when the brakes are applied.

The same thing can also happen to steel brake lines. Debris in the brake fluid, or a crushed or kinked line, can block the passage of hydraulic pressure to the brakes. In some cases, pressure will get through, but when the brakes are released, the blockage prevents pressure from releasing back to the master cylinder causing the brake to drag.

Replacement hose must be the same length as the original, with the same type of end fittings. A hose that is too long may rub against a suspension component or other parts, while a hose that’s too short may be stretched and damaged when turning or by excessive suspension travel.

CALIPERS

CALIPERS

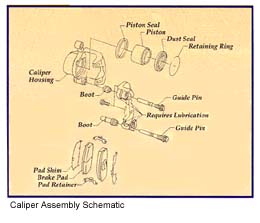

Disc brake calipers squeeze the pads against the rotors when the brakes are applied. Calipers come in two basic types: Floating and fixed. Floating calipers are the most common and are so named because they slide sideways on their mounts to center themselves over the rotor when the brakes are applied and released. Most have a single piston behind the inner brake pad, but some have two or more pistons.

Floating calipers ride on slides, bushings or pins. This hardware must be corrosion-free, undamaged and lightly lubricated so the caliper can move, otherwise it will stick and cause uneven pad wear (usually the inner pad wears more). Fixed calipers do not move and have pistons on both sides of the pads (usually one or two on each side). Uneven wear in a fixed caliper can be caused by a sticking piston.

Caliper service is required if a caliper is leaking brake fluid, if a piston is sticking or frozen, or if the pads show uneven wear. Many brake experts recommend rebuilding or replacing the calipers on high-mileage vehicles when the brakes are relined for preventive maintenance. Like any other mechanical component, calipers wear and corrode with age. Every time the brakes are applied, the back-and-forth motion of the caliper pistons produces a slight amount of wear on the piston seal and piston bore.

Moisture contamination in the brake fluid adds to the problem by allowing corrosion to attack the piston bores and the caliper pistons if they are steel or aluminum (which is why the fluid also needs to be changed every few years!). As the surface of the pistons and bores become pitted and rough, the seals wear even more and may begin to leak.

Also, as the pads wear, the caliper pistons move gradually outward. This exposes more of the piston to potential contamination and corrosion from dust or moisture that may get past the dust boot. If an old corroded piston is then shoved back into the caliper when new pads are installed, the piston seal will be riding on a rough surface. It won’t be long before the seal fails and the caliper starts to leak.

Brake fluid leaks are serious because fluid can contaminate the brake linings, causing them to grab or pull. Fluid loss can also lead to brake failure.

Even if a caliper isn’t leaking, it is still aging. Rubber piston seals and dust boots lose elasticity with age. Square-cut piston seals help retract the pistons and pads when the brakes are released. If the seals are old and hard, they may not pull the pistons back, allowing the pads to drag against the rotor. When dust boots get old, they often crack or split and allow dirt and water to enter the piston bore area. The result can be accelerated seal wear, piston corrosion and sticking.

Rebuilding or replacing the calipers when the brakes are relined restores the system to like-new condition, improves brake reliability and reduces the risk of leaks or other problems that might lead to a comeback and an unhappy customer.

On low-mileage vehicles, the caliper hardware should be cleaned, inspected and lightly lubricated with a high-temperature, moly-based brake lubricant. Ordinary chassis grease should never be used for this purpose. Badly corroded or damaged caliper hardware must be replaced.

CALIPER REPLACEMENT

Any caliper that is cracked, damaged, has worn mounting or slide surfaces, elongated pin or guide holes, bore damage or severe bore corrosion must also be replaced.

Preassembled “loaded” calipers can save time and reduce the chance of making an installation error because all of the clips, bushings and other parts you need are in one box – and the parts are all correctly matched.

Calipers should usually be replaced in pairs. But if you are replacing only one, the replacement caliper should have the same type of piston (steel or phenolic) as the one on the opposite side, and the same brand and type of friction material to maintain even brake balance side-to-side. A mismatch in friction may create a brake pull.

Loaded calipers are also a good choice for replacing rear calipers on vehicles with four-wheel-disc brakes. Overhauling a locking rear caliper is not an easy job because the self-adjusting mechanism inside the piston is difficult to disassemble, clean, lubricate and reassemble correctly. In many instances, the parts are too badly corroded to be reused anyway, and replacement parts may not even be available.

Finally, don’t forget to flush out all the old brake fluid and bleed the lines to remove air. Use the type of brake fluid specified by the vehicle manufacturer (DOT 3 or 4).