On certain Saab 9-5 models with B205E and B235E engines, the clip holding the turbocharger pushrod to the arm on the wastegate valve can come loose. If the clip comes off, the pushrod can slide off the pin on the wastegate valve arm. As a result, boost pressure control will not function and the valve disc will cause a rattling from the turbocharger.

In the case of a customer complaint, proceed as follows.

Symptoms:

• Low engine power output, little movement on the turbo pressure gauge and rattling from the turbocharger;

• Check engine light on; and

• DTC P1105 set.

Parts Required:

• 91 85 497 (CA: 30567751) — stainless-steel clip;

• 79 87 415 (CA: 30588378) O-ring; and

• Nuts for the catalytic converter, if required.

Service Procedure:

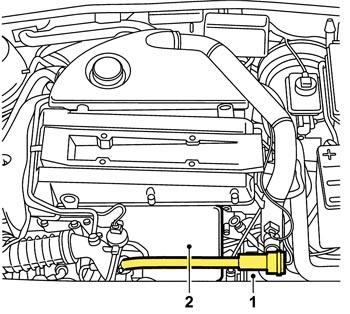

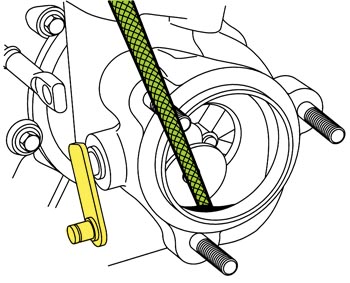

1. Undo the hose clip on the charge air pipe and the screw on the bypass pipe. Move aside the bypass pipe. See Fig. 1.

2. Remove the heat shield. See Fig. 1.

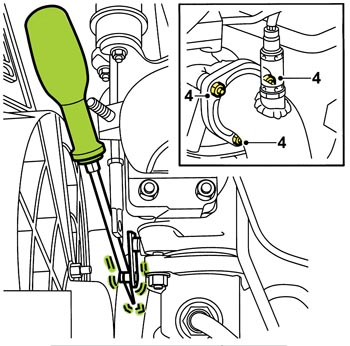

3. Gently tap the valve arm using a screwdriver to coax it back into its original position (counterclockwise). See Fig. 2.

4. If the valve arm does not return to its original position following the method previously described, unplug the oxygen sensor connector and remove the primary catalytic converter, or disconnect the front exhaust pipe from the turbocharger. Otherwise, perform only steps 8, 10 and 11.

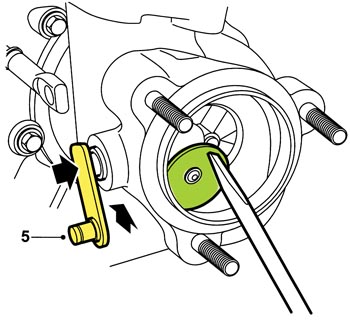

5. Press the tip of a screwdriver against the top right part of the valve disc while pressing in the valve spindle and raising the valve arm with your hand. See Fig. 3.

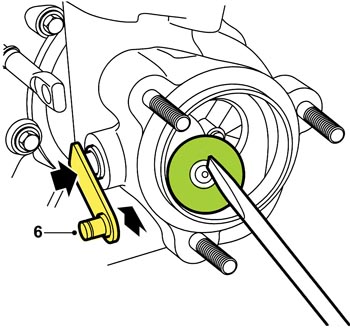

6. Press the tip of a screwdriver against the valve disc while pressing in the valve spindle and turning the valve arm farther to pass the edge of the exhaust turbine. See Fig. 4.

7. If it’s difficult to pass this edge, carefully file down the edge that hinders the valve disc with a round file. Check that the valve disc is undamaged. See Fig. 5.

8. Connect the arm to the pushrod and secure it with the new clip specified above.

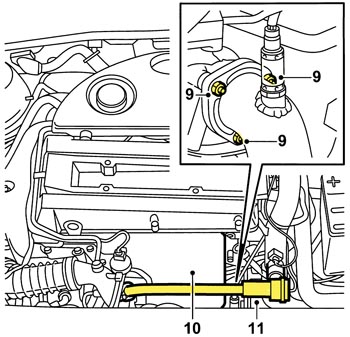

9. Fit the primary catalytic converter and plug in the oxygen sensor, or fit the front exhaust pipe. Grease the studs with 30 20 971 thread paste. Tightening torque: 24 Nm (18 lbf.-ft.). See Fig. 6.

10. Fit the heat shield. See Fig. 6.

11. Fit the bypass pipe using a new O-ring. SeeFig. 6.

Courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.