The oxygen (O2) sensor is the master switch in the fuel control feedback loop. The sensor monitors the amount of unburned oxygen in the exhaust and produces a voltage signal that varies from about 0.1 volts (lean) to 0.9 volts (rich). The computer uses the O2 sensor’s signal to constantly fine tune and flip-flop the fuel mixture so the catalytic converter can do its job and clean the exhaust.

If the O2 sensor circuit opens, shorts or goes out of range, it usually sets a fault code and illuminates the Check Engine or Malfunction Indicator Lamp. However, some O2 sensors that are badly degraded will continue to function well enough not to set a fault code, but not well enough to prevent an increase in emissions and fuel consumption. The absence of a code or warning lamp, therefore, doesn’t mean the sensor is doing its job.

The performance of the O2 sensor tends to diminish with age as contaminants accumulate on the sensor tip and gradually reduce its ability to produce voltage. This kind of deterioration can be caused by a variety of substances that find their way into the exhaust such as lead, silicone, sulfur, oil ash and even some fuel additives. The sensor can also be damaged by environmental factors such as water, splash from road salt, oil and dirt.

As the sensor ages and becomes sluggish, it may not allow the computer to flip-flop the fuel mixture fast enough to keep emissions within acceptable limits. If the sensor dies altogether, it will cause the feedback control system to go back into open loop with a fixed, rich fuel mixture. Fuel consumption and emissions go up, and the converter may suffer damage if it overheats.

A recent EPA study found that 70 percent of the vehicles that failed an I/M 240 emissions test needed a new O2 sensor.

So for these reasons, it’s important to check the sensor’s performance periodically, as when doing routine maintenance (like changing the spark plugs) or diagnosing a vehicle for an emissions failure or converter failure.

The best way to check O2 sensor performance is with a digital oscilloscope. A good sensor should produce a waveform that flip-flops from near minimum (0.1 to 0.2v) to near maximum (0.8 to 0.9v). O2 sensors in feedback carburetor applications have the slowest flip-flop rate (about once per second at 2,500 rpm), those in throttle-body injection systems are somewhat faster (2 to 3 times per second at 2,500 rpm), while multiport-injected applications are the fastest (5 to 7 times per second at 2,500 rpm).

When the mixture is made artificially rich by injecting some propane into the intake manifold, the sensor should respond almost immediately (within 100 milliseconds) and go to the maximum (0.9v) reading. Likewise, making the mixture artificially lean by opening a vacuum line should cause the sensor’s output to drop immediately to the minimum (0.1v) reading.

Another approach is to replace the O2 sensor periodically for preventive maintenance. Instead of waiting for the sensor to go bad, you replace it before it can cause trouble.

Though most new car manufacturers do not require O2 sensors to be replaced as a regularly scheduled maintenance item, aftermarket suppliers are touting the benefits of O2 sensor replacement as preventive maintenance. Bosch, for example, now lists specific mileage recommendations by year, make and model in its catalog for replacing O2 sensors.

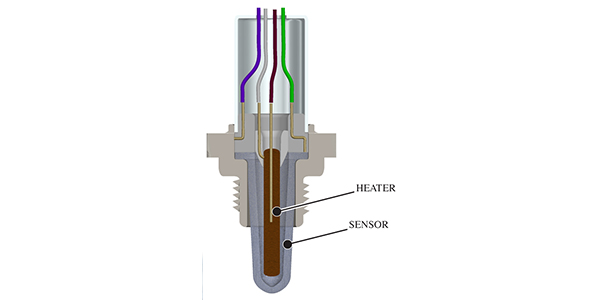

Oxygen sensor manufacturers recommend replacing unheated 1- or 2-wire wire O2 sensors on 1976 through early 1990s applications for preventive maintenance every 30,000 to 50,000 miles. Heated 3- and 4-wire O2 sensors on mid-1980s through mid-1990s applications should be changed every 60,000 miles. And on OBD II-equipped vehicles, the recommended replacement interval is 100,000 miles.

Telling your customer that he should replace something that hasn’t yet failed for preventive maintenance can be a tough sell, especially if the customer has never heard of an oxygen sensor or has no understanding of how it affects emissions, fuel economy and performance. So the key here is educating your customers.

First, they need to be told that their vehicles have an oxygen sensor. Second, they need to be told what the sensor does and how important a good sensor signal is for good fuel economy, emissions and performance. Lastly, you need to explain the benefits of replacing the sensor for preventive maintenance.

If a vehicle with a sluggish O2 sensor is only averaging 18 mpg, and is driven 12,000 miles a year, replacing the sensor can save $100 or more a year in fuel bills if the new sensor improves fuel economy 10 to 15 percent (which it often can). It’s not a big savings, but there are other benefits, too. As we said earlier, bad O2 sensors are a major cause of emission failures. Bad O2 sensors are also a leading cause of catalytic converter failures.

Replacing O2 sensors for preventive maintenance, therefore, is something you should recommend not only to restore peak fuel efficiency and to minimize exhaust emissions, but to also prolong and protect the life of the converter.