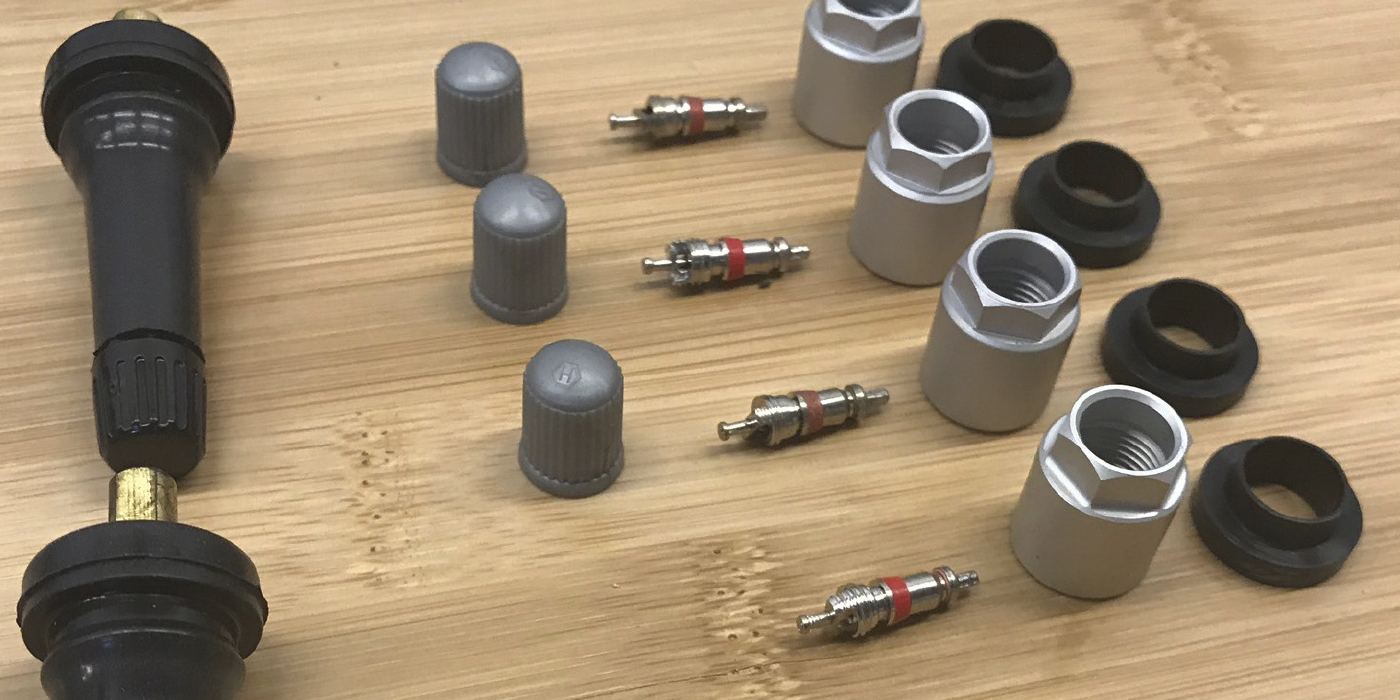

Every OEM that uses metal valve stems for its TPMS sensors advises that if any corrosion is seen on the valve stem, it should be replaced. If the valve stem breaks due to corrosion, it will result in rapid deflation of the tire.

Every OEM that uses metal valve stems for its TPMS sensors advises that if any corrosion is seen on the valve stem, it should be replaced. If the valve stem breaks due to corrosion, it will result in rapid deflation of the tire.

The nut has a bonded lubricant to help provide the proper torque required for seating a new grommet, in addition to the engineering advantages it provides. If a nut is reused, the anodized surface may be scratched away and corrosion may occur between the sensor, wheel and stem. It may even make the nut impossible to torque to the correct specifications or remove due to corrosion on the threads.

Corrosion can cause retaining nuts to split, resulting in the sensor dropping into the tire and creating a potentially catastrophic situation. Replace the service kit each time a tire is replaced. Ignoring these components when installing a new tire may leave the assembly with a worn-out seal and partially corroded components on the valve stem that can later fail and cause air loss and damage to the sensor.

If a valve stem is compromised by corrosion, the simple act of attaching an air chuck can cause the stem to snap. Likewise, using a longer truck-style air chuck can create enough leverage to snap even a good stem.