The Ford® Bronco® is America’s original sports-utility vehicle, built for fun and distinguished by its toughness and durability. So when you need to upgrade or repair a Bronco, choose top-quality parts that match the rugged strength of these trucks. Specifically, the axle shafts, axle bearings, ball joints, and ring and pinion gearing in Broncos built from 1966 through 1996 are all components that will likely need attention at some point. Choose OE-quality parts that are application-engineered for the Bronco to keep these rigs on the road for years to come.

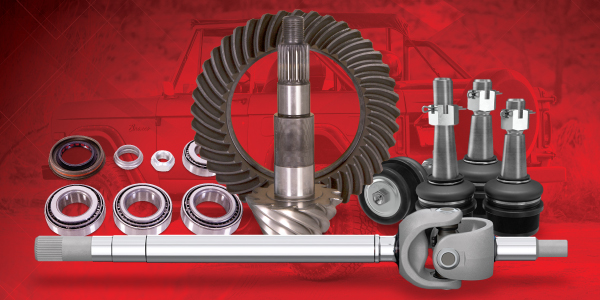

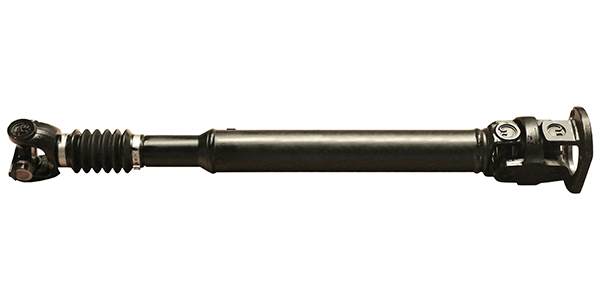

For a replacement axle shaft on a 1971-1977 Bronco with a Dana 44™ axle, seek out a nickel chromoly axle shaft that’s engineered for optimum strength. SAE-4340 nickel chromoly steel construction can provide toughness and abrasion resistance. If the shaft is subjected to heat treatment processes during manufacturing, this will ensure ideal hardness throughout the part.

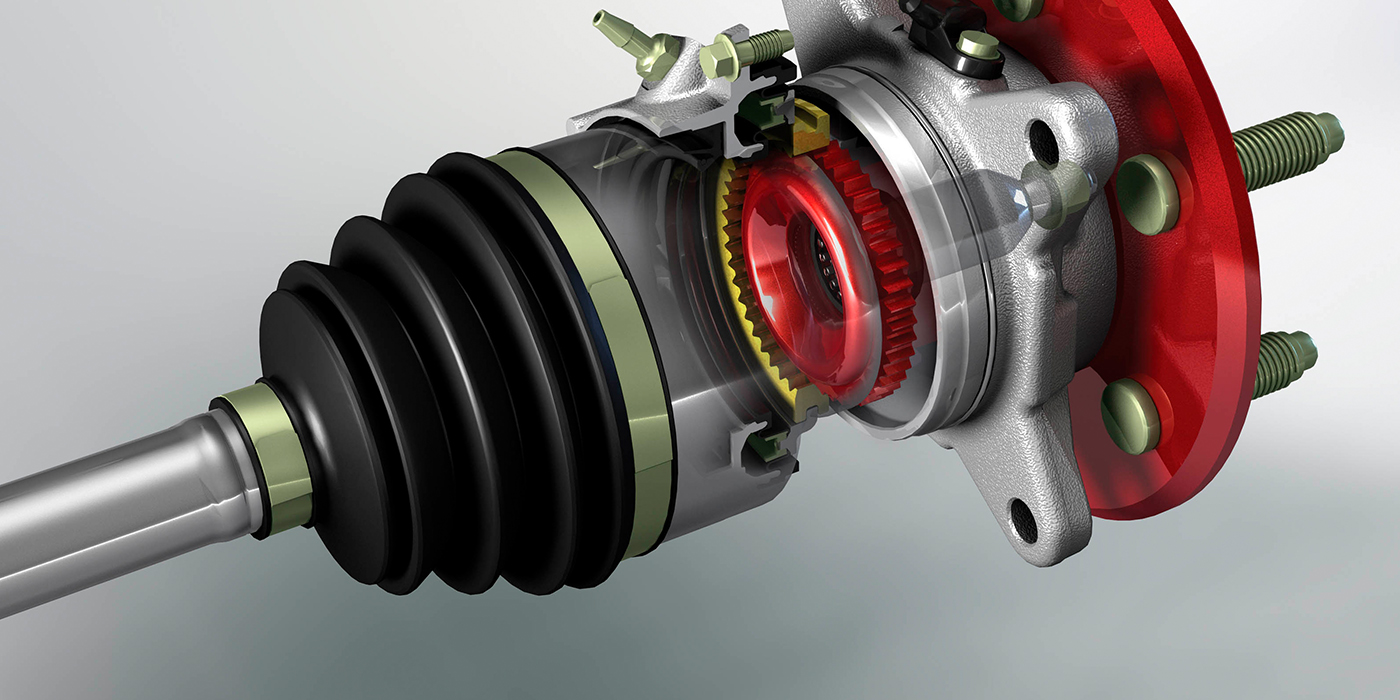

Are you repairing a hard-working family vehicle, or installing new bearings when regearing a Bronco for maximum strength? Using a kit can save you money and downtime when regearing or fixing axles in older-model Broncos manufactured through 1992. There are lots of axle bearing kits out there to choose from; take the time to find one with the highest-quality mix of shims, bearings, cups, and cones to avoid the aggravation of additional repairs in the future. If your kit also includes premium oil seals and the required RTV compound, you’ll be two steps ahead before you even begin.

The factory ball joint in a Bronco with a Dana 30™ or Dana 44™ axle is engineered for strength, yet upgrading a Bronco to larger-than-stock tires generates additional stress. This stress can damage and quickly wear out the OE ball joints and contribute to uneven tire wear. For increased resistance to stressors like deflection and deformation, a high-performance ball joint that’s designed with metal-on-metal construction is an ideal solution.

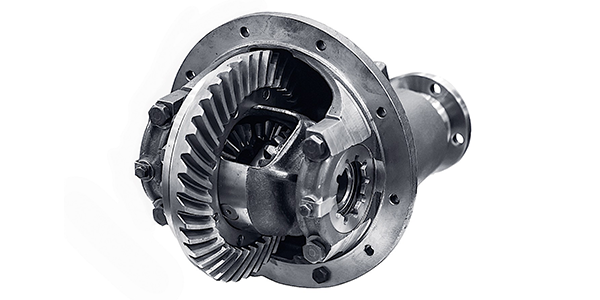

Modifications to a 1966-1996 Ford Bronco may ultimately indicate a gear ratio change. Every fan of rugged, off-road-ready rigs knows that you simply can’t skimp on the ring and pinion gearing. Top-quality gearing can provide the easiest possible set-up, a quieter ride, and unsurpassed strength.

If you’re in the market for any of these aftermarket parts, why not choose components from companies that have been a part of Bronco since the beginning? Spicer® parts from Dana have been integral to the iconic Bronco since the first one rolled off the line in 1966—and they’re now featured on every 2021 and newer Bronco. Dana and Spicer genuine service parts are application-engineered specifically for the Bronco, and Dana’s time-honored, rigorous standards assure dependability and durability.

See for yourself how Dana design, testing, and manufacturing processes all work together in Spicer parts. In Spicer nickel chromoly axle shafts, statistically-controlled manufacturing processes and top-quality materials yield a factory-grade fit—and strength that can exceed OE standards. Spicer bearing kit components are precisely selected by the Dana engineering team for maximum performance, and each kit comes with exactly the parts you need. When you need a heavy-duty ball joint for a 1966-1991 Bronco, the Spicer performance ball joint kit replaces the OE plastic-on-plastic design. And finally, Spicer ring and pinion gearing for Ford Broncos with a Dana 30™, Dana 35™, or Dana 44™ axle offers a factory-grade fit and up to double the life of non-genuine parts.

When it’s time to replace or upgrade Ford Bronco drivetrain or axle components, get the highest-quality aftermarket parts out there. On the highway or off-road, trust Spicer parts to support and enhance the capable, ready-for-anything Bronco.