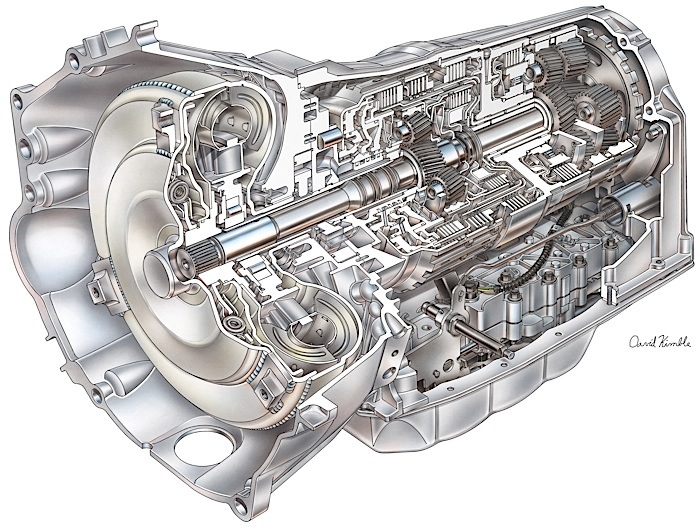

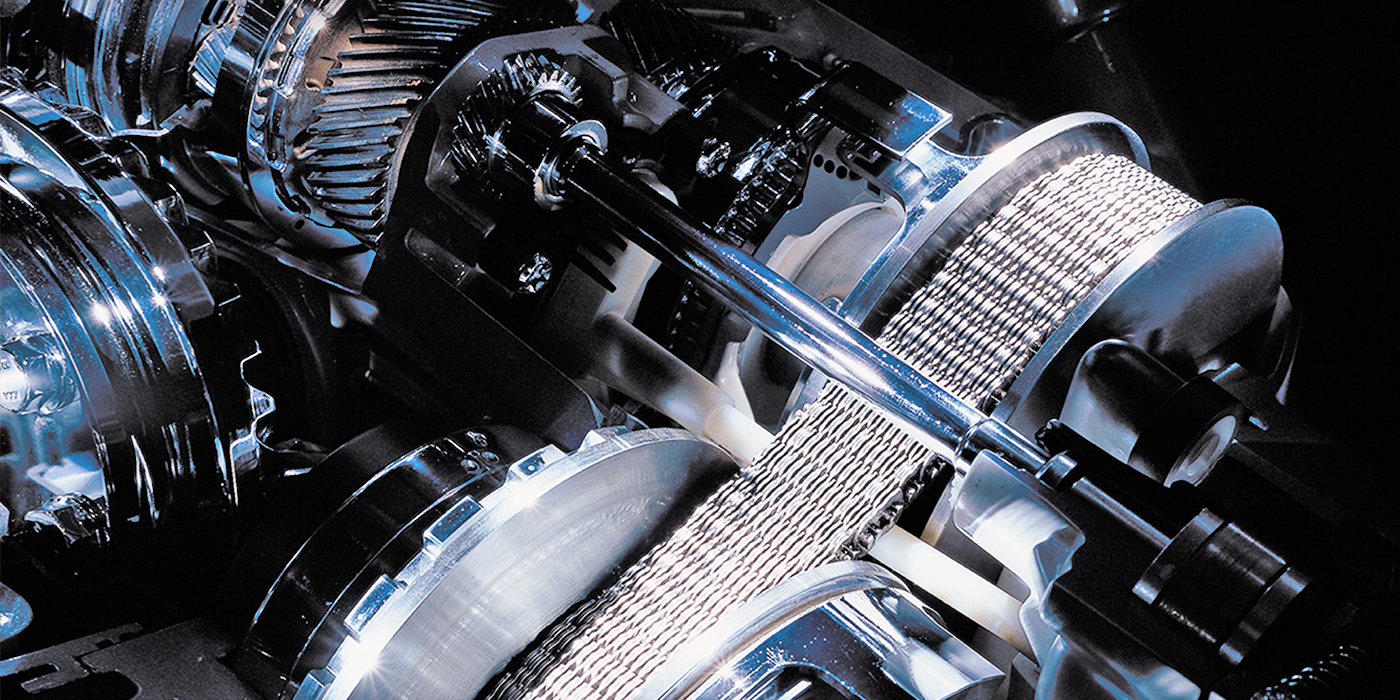

When replacing a transmission, you have many options. Remanufactured transmissions are disassembled and rebuilt in a factory environment. Rebuilt transmissions are those that are characteristically cleaned, inspected and wear items like clutch plates and seals are replaced. These transmissions usually come with only a short-term warranty.

When replacing a transmission, you have many options. Remanufactured transmissions are disassembled and rebuilt in a factory environment. Rebuilt transmissions are those that are characteristically cleaned, inspected and wear items like clutch plates and seals are replaced. These transmissions usually come with only a short-term warranty.

Used or salvage transmissions can be pulled from anywhere and installed in a car without being disassembled, internally cleaned or inspected. Typically, these are removed from vehicles in recycling yards. This is usually an option when affordability is the bottom line for the customer.

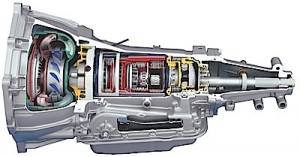

Remanufactured transmissions, on the other hand, are constructed to meet like-new specifications. This means that all the core pieces and parts of the transmission are examined and scrutinized against original equipment specifications. These parts are gone over to ensure correct dimensional tolerances are met and that operating pressure is consistent with OE design. If any parts are needed in a remanufactured transmission, these will typically either be new or requalified to precise standards. These transmissions must go through testing in order to certify they meet the high standards of the remanufacturing party.

Because more care (and money) goes into the construction of remanufactured transmissions, it logically follows that more care should go into the installation of these systems.

Because more care (and money) goes into the construction of remanufactured transmissions, it logically follows that more care should go into the installation of these systems.

Remanufactured transmissions have a more extensive warranty than rebuilt transmissions, but oversight on the part of the installing technicians can lead to problems and even having the warranty voided.

Eric Nail, customer service technician for Jasper Engines and Transmissions, talked with Brake and Front End about best practices for installing these systems the right way the first time. As an advanced-level transmission tech, Nail troubleshoots transmission issues and helps diagnose when transmissions need to be replaced.

What are some of the main things technicians need to be mindful of when installing remanufactured transmissions?

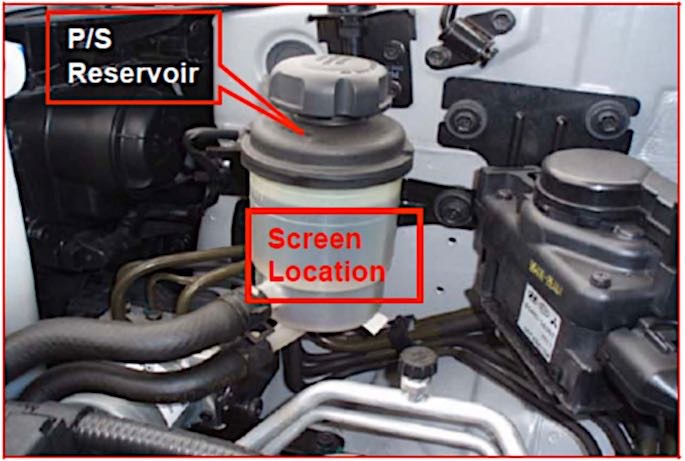

The common thing that we look for, and this goes for every unit we send out, is cooler restrictions. We give three options: One is replacing the radiator so you know there are no restrictions there; you can also purchase an auxiliary cooler bypassing the radiator, and use it as a standalone system; or you can flush it with the flush machine that we rent out that does a thorough job of flushing as well. That is probably the biggest thing you find in terms of being proactive on installing these — making sure the cooling system is in good working condition and it’s not restricted.

When you hear of problems due to installation practices, what are the most common errors?

A lot of times a technician will use a can of flush. And even though you might be able to use a can of flush to get oil through the system, if it’s a honeycomb-style cooler, you’re still going to have restrictions.

The other item that comes to mind is check valves that are in place in cooling lines. You have to make sure you have a good check valve that doesn’t cause any sort of overheating, because if the one-way check valve is defective, then it can prevent the oil from reaching the oil cooler itself. This can also give you internal damage and cause the transmission to overheat. That is something to be mindful of any time you have a check valve in the line or in the cooler itself.

What do you tell technicians about using the correct transmission fluid?

What do you tell technicians about using the correct transmission fluid?

In terms of fluid type, make sure you’re using the right kind of transmission fluid specific to that vehicle, because if you use a multipurpose-type fluid, you can create shudders and slippage. So, you always want to make sure you’re using those OE-recommended fluids and not a multipurpose transmission fluid.

Making sure you have the right fluid and have a good cooling system are two fundamental things Jasper recommends with every item we send out. Any TSBs that come with the unit, and any relearns you need to do (especially with grounds —make sure you have good grounds), make sure you’re following proper procedures.

What is one of the main areas of concern you get calls about from technicians?

One of the things you deal with a lot is torque converter shudders. That can be anything from the wrong type of fluid to engine-related concerns. Right now we’re seeing sensors on the engine, such as the mass air flow sensor, causing transmission shifting concerns. We hear about this quite a bit, almost on a daily basis. There is also a TSB published for that same reason.

Is there a concern about people taking on transmission jobs that might be a little bit outside their area of expertise?

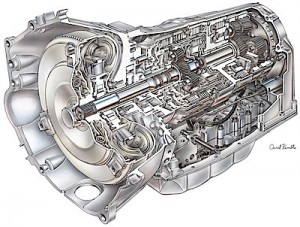

You see a lot more of these transmissions that have the control module internally. And if you don’t have the proper equipment to calibrate those units, per your VIN, that can be a hurdle to get over. We offer programmers to go along with the unit if the shop needs one to program the transmission control module internally in transmissions that have those. Not all have them, but late-models do. You can’t just do a quickflash anymore, a relearn, you have to program it through your VIN.

What do shops need to do in terms of communicating with the customer after installation?

Since these are remanufactured transmissions, and if you’re using your existing OE cooling system, you could have a failure where there is some contamination. We do recommend, on all of our units where the filter is serviceable, bringing it in after 5,000 miles for a filter and fluid change to be proactive in getting any of the transmission debris out that could be the result of the brake-in period. This gives you a chance to look inside there and make sure everything is good to go.

Going back to the relearns, with some of them, you just have to drive them even after you’ve performed the relearn with the scan tool; you still have to drive them to get more miles on them because the shift adapts will still eventually take place on some particular units. We get calls on that, where you may have a certain shift characteristic and we know it’s just going through the relearn process. So, explaining this to the customer, you have to let them know that it’s resetting the shift adapts, and the longer you drive it, the better it will become. We actually supply that bulletin with the units themselves on those units where we feel that it’s important to know the installation instructions. Essentially, we provide bulletins on shift characteristics the user may experience.

Any other best practices technicians should be aware of in dealing with remanufactured transmissions?

I think it’s big that when a vehicle comes into your shop with a failure, you need to understand why that unit failed in the first place so that you can be mindful of what to look for on the vehicle side of things prior to installing a remanufactured unit. It’s always important to document that, too. This might help you connect the dots and say, ‘OK, here is what’s going on,’ in case you need to reference that.