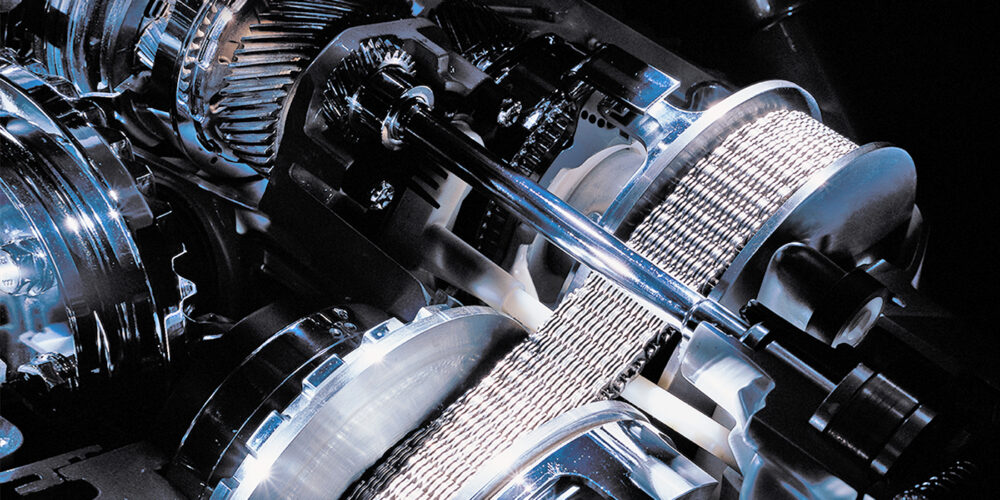

Transmissions – CVT

Knowing what the common issues are & understanding the options available to isolate & fix problems are the keys to success.

All transmission models have unique problems that are common to that model; JATCO CVT units are no exception. Technicians are facing an uphill battle when it comes to diagnosing and repairing CVTs if they don’t have the right information on hand. Knowing what the common issues are and understanding the options available to isolate and fix problems are the keys to a successful repair.

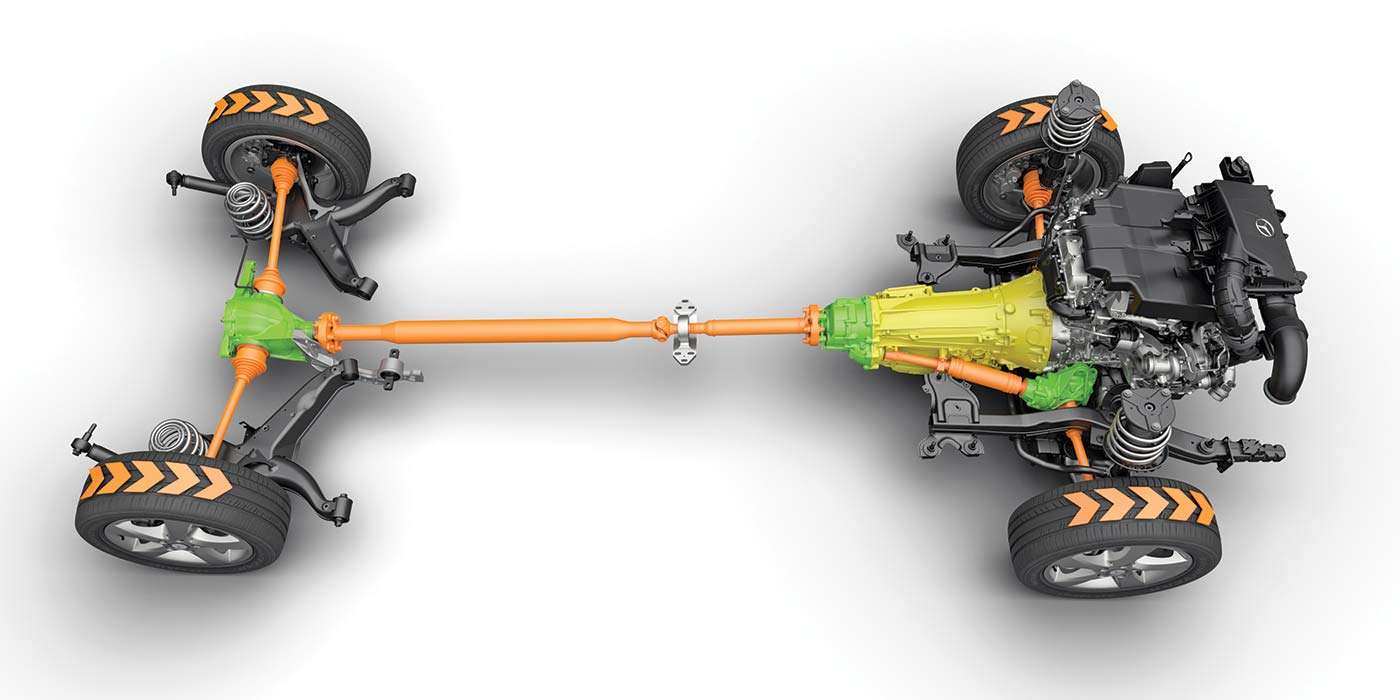

Simplifying AWD Systems

No matter the manufacturer, there is almost always an all-wheel drive (AWD) option.

Manual Transmission Service

Parts that wear out must be replaced.

Transmission Fluid Hydraulics

You need to know how transmission fluid flows inside an automatic transmission.

Advanced Wheel Bearing Diagnostics

Can a bump set a wheel speed sensor code?

Other Posts

BMW Transfer Case Service

The transfer case is a rather unique design in the way that it operates a clutch pack mechanically, not hydraulically.

How Well Do You Know Your Driveshaft?

There are three types of modern driveshafts with multiple configurations.

Transmission Service

The following is an example of a dishonest vehicle and how to go about catching it in its lie.

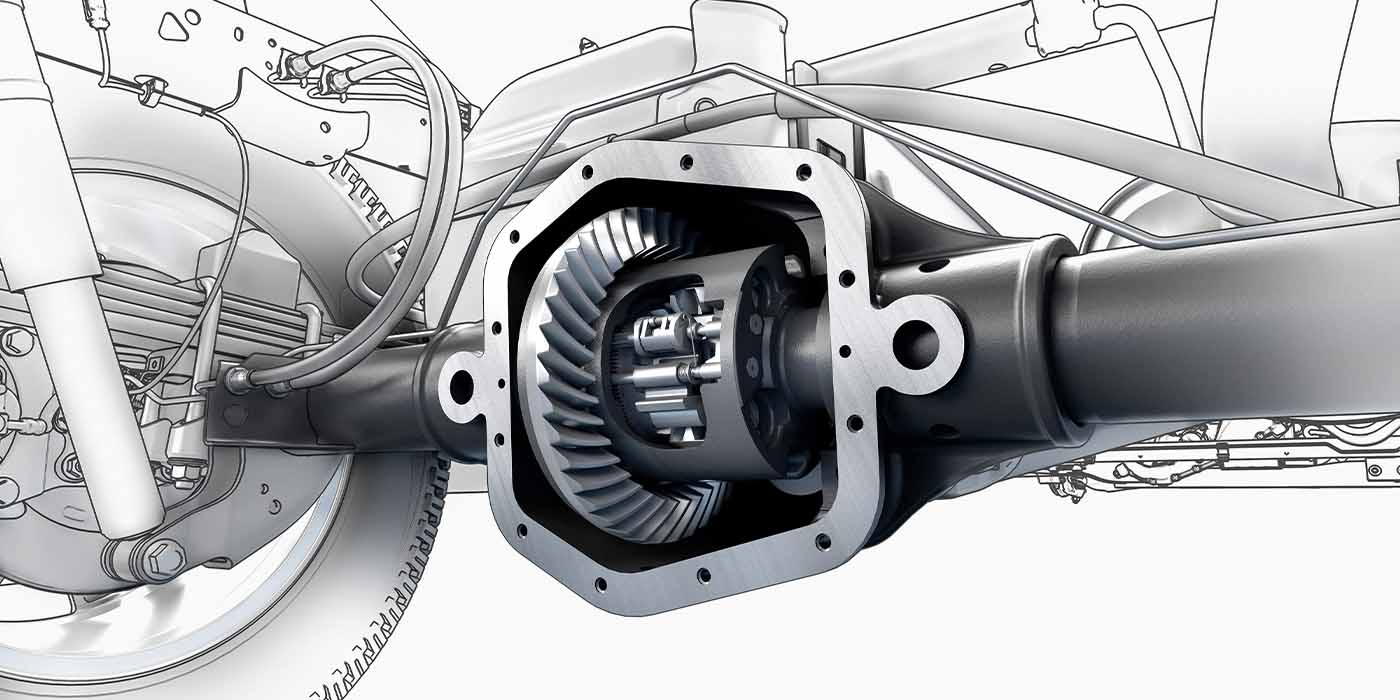

Limited-Slip Differentials And Diagnostics

A limited-slip differential helps to control the tangential forces.