How To Diagnose NVH Complaints In Drivetrain Components

Thanks to advanced technology, modern vehicles operate with fewer noise, vibration and harshness (NVH) complaints than ever before. Consequently, when a NVH issue arises, it’s most likely caused by worn drivetrain components like universal joints, constant velocity joints or wheel bearing hub assemblies. In any case, NVH complaints can often be the most challenging to diagnose when you can’t duplicate the driving conditions under which they occur.

Lift Your Shop’s Profit Potential; Align It With Your Goals

Like all other shop tools and equipment, alignment equipment and lifts have come a long way over the years. Advances in technology have made these automotive repair shop essentials more profitable and productive — increasing a shop’s ROI (return on investment) faster than ever. Alignment Equipment Alignment systems that use digital imaging technology offer shops

Active Drivetrains And Differentials

Vehicles equipped with 4×4 or all-wheel-drive (AWD) systems are designed to provide advantages throughout the year, but winter tends to bring these vehicles into focus.

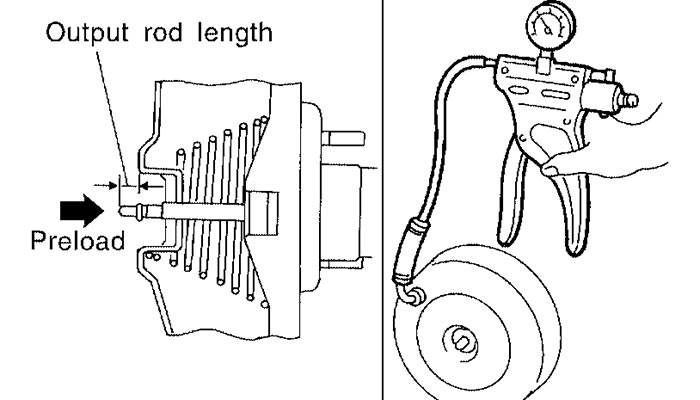

Brake Service Case Study: Nissan Frontier

Bob Dowie looks at some of the undercar issues he has faced with Nissan vehicles over the years and discusses how to deal with some common issues you may see with them.

Preventing Wheel Bearing Failure

Most manufacturers recommend lubrication at 24,000 miles for the front-wheel bearings on rear-wheel drive vehicles, but bearings often are not lubricated until the brakes are replaced. That means bearings may go nearly twice as long as recommended before being relubricated, which can lead to problems.

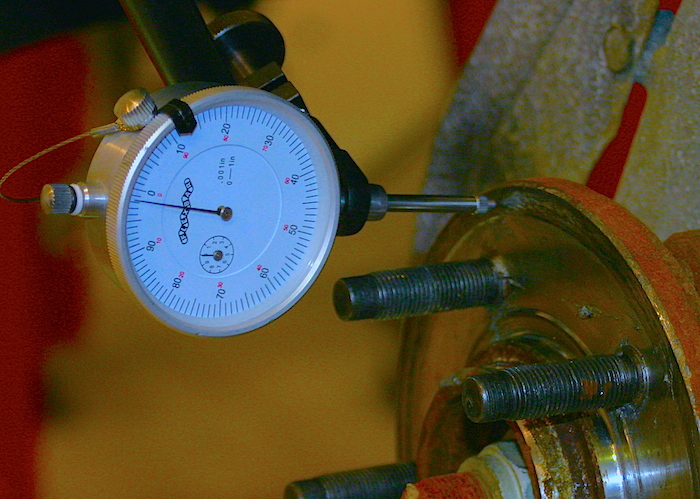

Torque And Runout: Measure Twice, Install Once

There are two critical measurements when installing a modern hub unit or cartridge bearing: torque and runout in the flange. Ignoring these critical numbers to save time will only lead to more comebacks and angry customers.

Wheel Bearing Torque Dos and Don’ts

While it may appear to be easier to use an impact wrench, it is not recommended. OEM and bearing manufacturers always recommend using a torque wrench for installation. During removal, an impact wrench can damage the axle nut threads and shock the CV joints. It can also create a false sense of security when adjusting a nut or bolt, which may be under or over torqued.

Alignment Specs: 1997-2004 Chevrolet Corvette

With different front and rear run-flat tire sizes, the 1997-2004 Corvette must be aligned every 20,000 miles or when the smallest amount of abnormal tire wear is present. If the customer does not have this service performed, even the slightest amount of extra toe, camber or caster can result in an expensive tire replacement bill.

Performing an alignment on a C5 Corvette is actually easier than on most vehicles because most of the adjustments are built into the vehicle. Also, you can adjust the ride height without replacing parts. But, you need to take care and be aware of what makes the Corvette different than most vehicles.

Tech Tip: SKF Offers Preventive Maintenance Recommendations and Tips for Avoiding Bearing Failure

A recent technical bulletin by SKF provides preventive maintenance recommendations for avoiding premature bearing failure, including tips on how to prevent repeat failures and assure customer safety.

Tech Tip: Diagnosing and Servicing 4WD Bearings

4WD operation can be hard on wheel bearings and seals. The most common complaint you’ll encounter is no 4WD operation, which can usually be traced to problems with the vacuum-actuated front hubs. Some manufacturers require that the driver shift the transfer case into four-wheel-drive, choosing either high- or low-range gearing. The driver must then flip a switch that opens a vacuum-control valve, sending vacuum to the locking front hubs and engaging them to ….