Service Procedure:

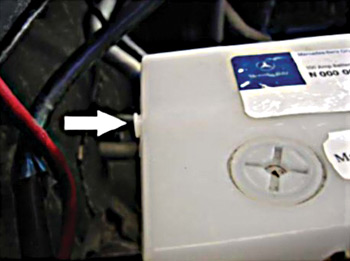

1. Insert plug in the rear battery vent hole (See Fig. 1, arrow).

2. Attach an elbow pipe with approximately a 25 cm hose on the front battery vent hole (See Fig. 2, arrow).

3. Fasten a clip to the battery box cutout using a cable tie (See Fig. 3, arrow).

4. Fasten the receptacle to the battery box using a cable tie (See Fig. 4).

5. Route the vent hose (See Fig. 5, arrows) and attach it to the receptacle.

Warnings: Battery electrolyte contains sulfuric acid that can cause severe caustic burns to the skin and eyes. Exercise  strict caution when handling damaged lead-acid batteries (i.e. when removing them from accident-damaged vehicles) because of the sharp edges on the fractured housing and direct contact with the lead plates.

strict caution when handling damaged lead-acid batteries (i.e. when removing them from accident-damaged vehicles) because of the sharp edges on the fractured housing and direct contact with the lead plates.

• Risk of explosion from gas — charging lead-acid batteries produces a highly explosive gas mixture.

• Risk of poisoning and internal caustic burns from swallowing battery electrolyte.

• Risk of caustic burns to the eyes and skin from battery electrolyte, electrolyte mist and from handling damaged lead-acid batteries.

• NO fire, sparks, open flames or smoking.

• Wear acid-resistant gloves, clothing and eye protection.

• Pour battery electrolyte only into suitable, appropriately marked containers.

Refer to WIS document AS54.10-Z-0001-01A for more detailed battery-handling information and precautions (including “Possible Hazards: Risk of Explosion, Risk of Poisoning, Injury Hazard,” “Protective Measures/Rules of Conduct,” “First Aid Measures,” “Fire Protection Measures” and “Warning Instructions For Lead Acid Batteries”).

Courtesy of ALLDATA.