Models

2006-2010 MX-5, 2004-2010 RX-8, 2007-2010 CX-7, 2007-2010 CX-9, 2004-2010 Mazda3, 2004-2010 Mazdaspeed3, 2006-2010 Mazda5, 2008-2010 Mazda6

Service Precautions

Service Precautions

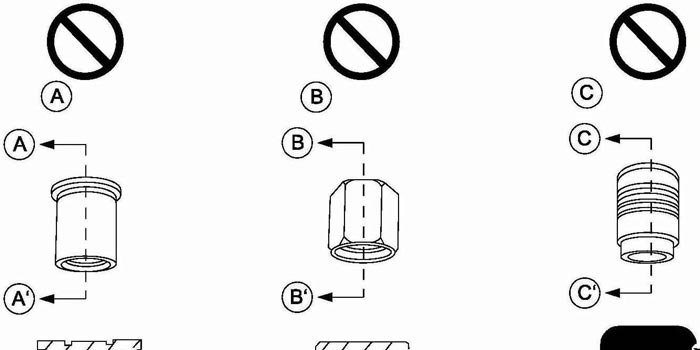

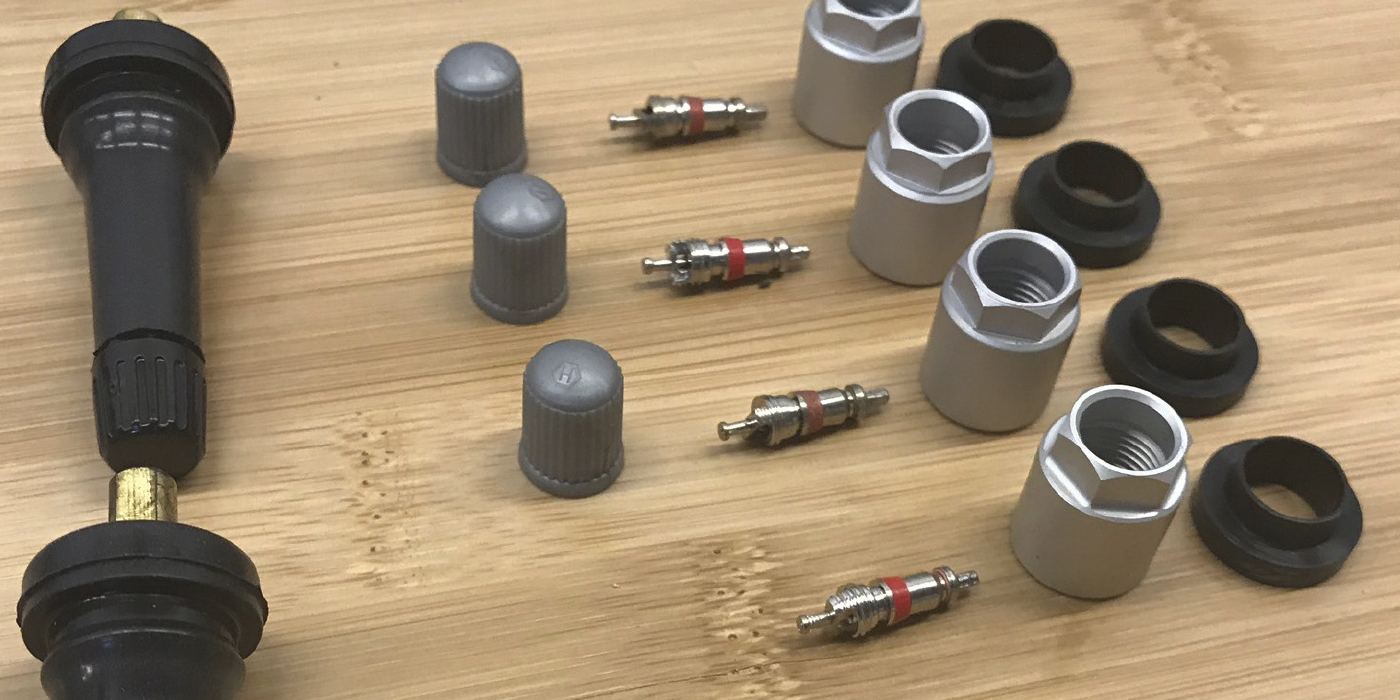

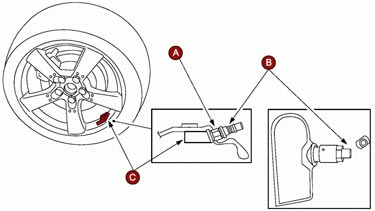

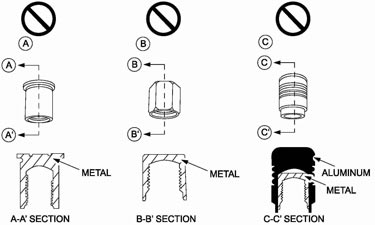

1. DO NOT use metal stem caps. Some vehicles may experience the aluminum valve stem (B) breaking off of the TPMS wheel unit (C) when removing aftermarket valve stem caps during procedures such as routine checking of air pressure in tires.

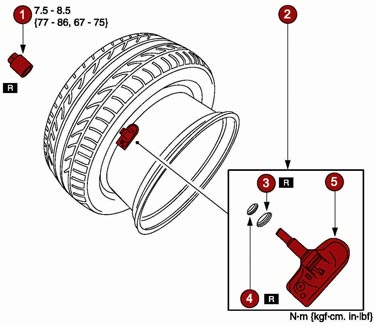

TPMS sensor nut (A): Initial torque 67-75 in-lbf (7.5-8.5 Nm)

Some aftermarket valve stem caps are made of metal or have thread inserts that are made of metal. Examples of these types of aftermarket valve stem caps are shown to the right. When metal and aluminum are together in such a condition, galvanic corrosion occurs between the aluminum valve stem of the TPMS sensor unit and the metal threads of the valve stem cap. This corrosion can cause them to fuse together, becoming difficult to remove by hand. When more force is used to remove the valve stem cap, the aluminum valve stem of the TPMS sensor unit will break off and the TPMS sensor unit will need to be replaced.

Typical aftermarket valve stem caps:

Typical aftermarket valve stem caps:

(A) – Metal

(B) – Chrome over metal

(C) – Aluminum with metal insert

This service bulletin can aid in informing customers of the damage that may be caused to the TPMS sensor units by installing these types of valve stem caps. Advise customers to use aluminum or plastic caps ONLY.

Also, ensure that the caps they choose to install DO NOT have a metal thread insert.

2. Torque TPMS sensor nut (A) and valve core (B) properly. Excessive torque on TPMS sensor nut and/or valve core may result in damage/breakage of the valve stem.

2. Torque TPMS sensor nut (A) and valve core (B) properly. Excessive torque on TPMS sensor nut and/or valve core may result in damage/breakage of the valve stem.

NOTE: The torque of the TPMS sensor nut slightly decreases after filling the tire with air. 17.7-26.6 in-lbf (2-3 Nm) is acceptable at this stage. DO NOT retighten after that.

3. Replace TPMS sensor nut when TPMS sensor (C) is detached. The TPMS sensor nut must be replaced with seal washer and seal when TPMS sensor is detached from the wheel.

1) TPMS sensor nut

2) TPMS sensor components

3) Seal washer

4) Seal

5) TPMS sensor

Courtesy of ALLDATA.