The most common reasons behind why a manual transmission fails are lack of lubrication, incorrect lubrication and improper or no clutch release.

COMPLEXITY OF LUBRICATION

Lubrication should be simple, but in the modern world NOTHING is simple. There was a time when virtually all stick transmissions ran on 90w gear oil. The synchronizer rings were brass or bronze, the cars and trucks shifted around 3,000 rpm and we had 3- and 4-speed transmissions. Ninety-weight did not like cold weather and generated multiple complaints to the manufacturer due to cold-shift problems. You needed two men and a boy to shift one of the units on a cold day until the fluid heated up.

Chrysler engineers, tired of the constant never-ending cold-shift complaints, specified ATF (automatic transmission fluid) for the manual transmissions, and cold-shift problems declined due to the very thin viscosity of the lube fill. There were some changes in the gear alloy used to make the gears as ATF had a much lower film strength than 90 weight gear oil. ATF was also better at finding any place it could leak, but better gaskets compensated for that.

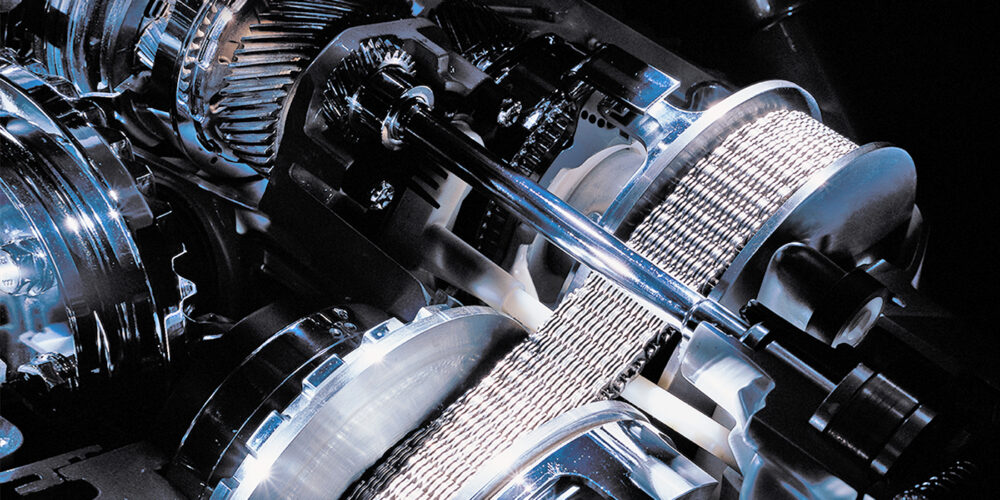

At this point in history the horsepower wars began, and 5-speed and 6-speed transmissions entered the market. Fuel economy and higher horsepower led to higher shift points, and the old synchro rings were not up to the task. The new designs were made of clutch paper like automatic clutch plates, Kevlar, carbon fiber and sintered metals, and each of these demanded a very specific fluid for lubrication. Single synchronizers morphed into dual- and triple-ring designs to shift at much higher revs and handle much more horsepower. The transmission installer now had to stock a variety of manual transmission lubes, as well as a growing number of lube fills for automatic transmissions that were undergoing the same development.

At this time, we started to sell fluid as self-defense against installers who would note the lube fill tag on the unit. But, if they were unable to provide it, they would put whatever was handy into the unit, which invariably generated a number of calls on Monday morning. Putting the wrong fluid in a unit with porous-synchro compounds would cause notchy grinding shifts, and after draining the unit of the wrong oil, might take two weeks of driving to get it right, resulting in loads of happy customers. Use the oil that is specified for the unit, even if it means you cannot deliver on time. Anything else is financial suicide and the death by 1,000 cuts.

CLUTCH RELEASE and SLAVE CYLINDER

Clutch release is something that seems to have never been taught in shop class. It is the single greatest cause of problems and damage in manual transmissions. Let us take a walk through history to study the changes. Back in the day, clutches were actuated by direct linkage from the clutch pedal to the side of the bell housing through a series of levers, rods, and springs. It was a simple system that failed as bushings, springs, and discs wore. Springs and levers gave way to flexible cables, and then to early hydraulics where the slave cylinder was mounted close to the bell housing.

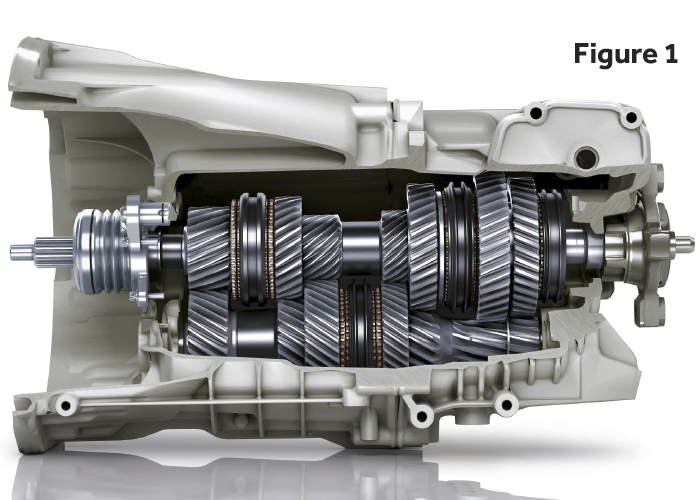

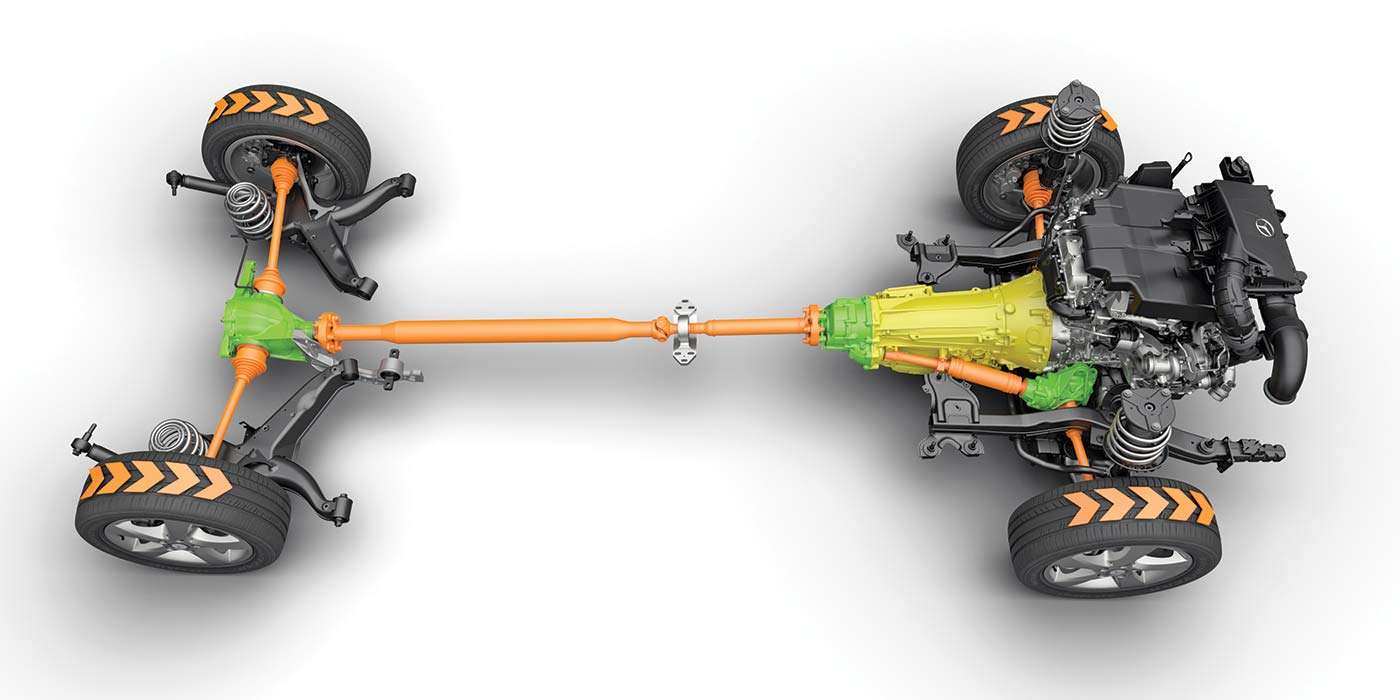

Then things began to get more complicated. The clutch can be adjusted to fully release the input of the transmission from the torque of the motor, which permits clean, wear-free shifts. The clutch can be adjusted where it never completely locks up and the disc will slip, harming the clutch pressure plate disc and flywheel, but causing no transmission problems. This shows up as slippage, with engine rpm walking away under acceleration and the forward speed of the vehicle falling off. Burning up the clutch set does not hurt the transmission. But now we have incomplete clutch release that destroys the trans in short order. What happens here is the driver steps on the clutch pedal and the slave cylinder (Figure 1) cannot move far enough to cause the pressure plate to completely release the clutch and creates a 50/1,000 air gap between the disc and the pressure plate and flywheel. This means that the torque of the engine is still turning the transmission input shaft, and as the driver tries to complete the shift, the engine power as well as the vehicle weight and momentum gets applied to the synchro ring and damage starts immediately.

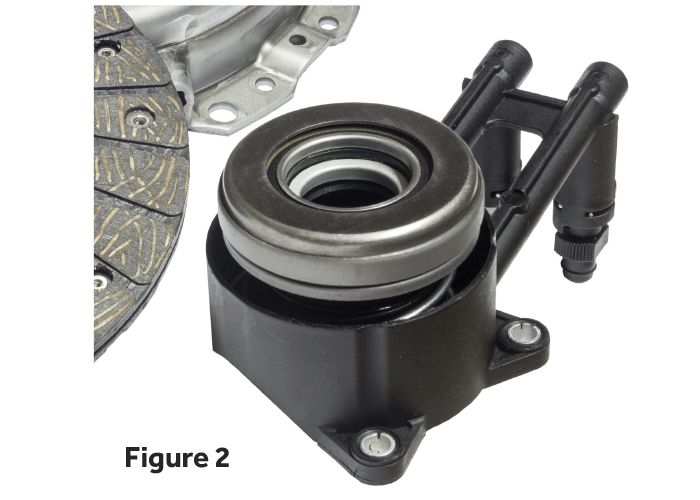

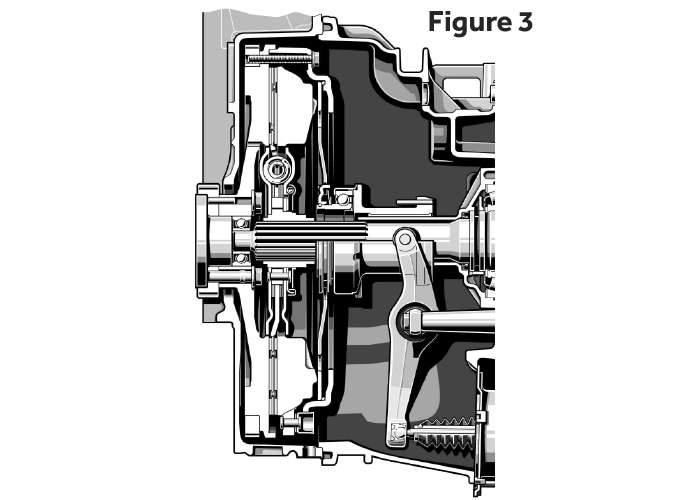

This situation worsened dramatically with the introduction of the concentric slave cylinder (Figure 2). This slave cylinder is hollow and mounts to the front of the transmission. It works fine if adjusted properly and if it’s properly bled of air in the hydraulics. However, one needs to measure the travel of the slave to the pressure plate fingers and determine if the slave cylinder needs to be shimmed forward toward the engine block. I have never seen any directions to do this on any packaging, but it is necessary to determine how much travel is required. This is not something you can see or measure when the trans is installed, but it is very easy to do before you bolt things together. To put this problem to bed, make a few measurements (Figure 3).

- Lay a straight edge across the fingers of the pressure plate.

- Measure the distance from the fingers of the pressure plate to the engine block surface to which the bell housing will be flush when bolted up.

- Make sure that the concentric slave is completely contracted toward the transmission face. Using a straight edge, measure from the contact section that will press on the pressure plate flange of the release bearing to the front flange of the bell housing that will bolt up to the engine block.

- Subtract the finger height measurement from the block surface from the bell housing to the release bearing – 0.780”-0.310”=0.470˝. We are looking for an air gap from the slave to the fingers of 0.190”. Subtracting 0.190” from 0.470”, we arrive at a 280/1,000 shim that must be placed behind the slave cylinder before it is bolted onto the trans to move the slave forward toward the pressure plate fingers and create a perfect clutch release. This is a very simple deal. In many cases, you will not need to make any shim changes when you are replacing stock parts with stock parts. When changing brands, doing custom-unit swaps, dual and triple disc from single disc, etc., always measure shim size and install the correct shim. You will save a tremendous amount of time and transmission damage by making a few simple measurements.

BLEEDING THE CLUTCH

Another issue that needs discussion is bleeding the clutch. Looking at most of the modern concentric slave cylinders, they are very difficult to bleed. They do not leave you adequate room to do this right and easily. The answer here is to extend the bleeder hose before installation. On the CTS-V Cadillacs, we made them three feet long and tied them up out of the way. Bleed the clutch from below. Use a power bleeder and the bubbles from below will naturally rise to the master cylinder. There are units that have the master cylinder mounted to the firewall at an angle (Ford Ranger). Jack up the rear of the truck until the master cylinder is level with the ground and bleed from below if you want to deliver this car sometime this month. Back in the ancient times, there was no way to get a good pedal on a SAAB without a power bleeder.

HELP THOSE WHO WANT HELP

Occasionally, I get calls on the tech line regarding the problems caused by lack of proper clutch release. We explain the procedures to rectify the situation and most callers seem to be grateful for the help and advice.

Lately, with some callers, there has been a sense of superiority, often due to information gleaned from the internet; a change in attitude. Some will tell me, I don’t know what I am talking about and my response is “why are you calling me?” I am an old-school guy who came up the hard way and was grateful for anything I was taught by experienced people. We are not impressed with today’s uninformed people who claim to have 2,000 friends on Facebook. I probably know about 6,000 people worldwide and they are acquaintances. I have two friends and they will come out at 3 a.m. in the rain to help me move a body with no questions.

Be kind to those who are helping you, give back whenever you can, learn something new more than once a day, and be proud of your profession and the people who made it what it is. Be a man, which means keep your word, and be courteous to all. Respect you have to earn.