Nobody would argue with the fact that engine balancing is right up there with “blueprinting” an engine. The goal is to equalize the reciprocating and rotating forces inside the engine so it will run smoother, last longer and achieve its maximum power potential.

Nobody would argue with the fact that engine balancing is right up there with “blueprinting” an engine. The goal is to equalize the reciprocating and rotating forces inside the engine so it will run smoother, last longer and achieve its maximum power potential.

Although balancing would seem to be most important for high revving performance engines, it can also provide benefits for relatively stock engines, as well as low revving heavy-duty diesel engines. When proper balance is achieved, it reduces NVH (noise, vibration and harshness) that can be felt inside the vehicle, whether it is a daily driver, a race car or over-the-road truck.

Better balance makes for a smoother running and quieter engine. But, even more importantly, proper balance also maximizes the engine’s longevity by reducing the pounding that imbalance produces on the crankshaft’s main bearings.

The centripetal forces generated by any imbalance increases exponentially in proportion to speed. Double the rpms and you quadruple the force. A 2 oz.-in. (ounce-inch) imbalance on a crankshaft will generate only about 14 pounds of centripetal force at 2,000 rpm. But when the engine revs to 8,000 rpm, that slight imbalance now becomes a pounding force of 227 pounds! The resulting thrashing motion that the crankshaft experiences with every revolution can pound the bearings and main caps to death over time – and the greater the imbalance, the greater the pounding force that is being exerted on the bearings and main caps.

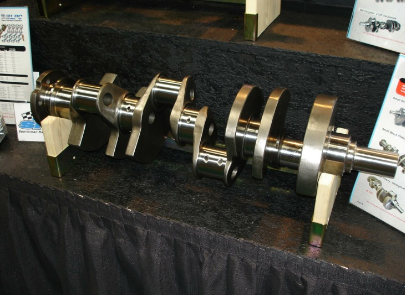

When a crankshaft spins, it wants to rotate around its center of gravity. That’s a basic law of physics. As long as the rotating weight is evenly distributed around the circumference of the crank, the center of gravity will line up with the center axis of the crank and the crank will spin smoothly without any wobble.

But, if there is an imbalance, it will offset the center of gravity and force the crank to oscillate from its true axis as it spins. Of course, the crank can’t wobble too much because it is held in place by the main bearings. Even so, the wobbling motion exerts a pounding force against the bearings and can even cause flexing and bending within the crankshaft itself if the forces are great enough.

Over time, this may lead to metal fatigue, stress cracks and crankshaft failure. It can also create annoying engine vibrations that can be felt throughout the vehicle, as well as harmonics in the camshaft and valvetrain that may result in a loss of horsepower.

Whether you have a large imbalance force acting on the crankshaft over a short period of time, or a relatively small imbalance force acting on the crankshaft over a very long period of time, the end result can be the same in either case: bearing fretting and fatigue that eventually leads to bearing failure and/or crank failure.

A high revving racing engine obviously needs a good balance to minimize these destructive forces, but balancing can be just as beneficial to low revving engines, too, including big over-the-road truck engines that only turn 1,800 to 2,800 rpm. Why? Because of the cumulative effect even a small imbalance can have on engine longevity.

Recognizing this, the auto makers have tightened up their balance tolerances in recent years to not only reduce NVH but to also extend engine durability. What used to be “race only” balance tolerances are now everyday production tolerances for many engines. Today’s lighter and higher revving engines can’t handle as much imbalance as older, heavier cast iron engines, so they are typically balanced to much closer tolerances.

Little Tolerance for Imbalance

The “old school” tolerances for balancing used to be plus or minus 2 ounces for stock engines (56 grams), half an ounce (0.5 oz. or 14 grams) for street performance and two-tenths ounce (0.2 oz. or 5 to 6 grams) for racing engines.

These numbers provided relatively good results with the engines and speeds that were common a couple of decades ago, but they are not even in the ballpark with today’s stock and racing requirements.

Most electronic balancing equipment that’s on the market today can easily achieve balances to within 0.1 grams (0.004 oz.), or even less for specialized applications such as turbocharger impellers that spin at extremely high rpms.

A dime weighs 2.268 grams (0.08 oz.). If you glued a dime to the outside edge of a counterweight on a crankshaft, it might not cause much of an imbalance in a low revving stock engine, but it would be too much of an imbalance for most performance engines.

Most racers today want their cranks balanced to within one ounce or less, and many of the big boys (NASCAR, ProStock, etc.) will aim for fractions of a gram. On some of Ford’s newer V6 engines, the factory balance is within 0.16 oz.-in. (4.5 grams) – which is old school racing tolerances. It’s important to keep this in mind because any time you are rebuilding a late model engine or a performance engine and change internal parts (pistons, wrist pins, rods or the crank), you change the balance.

The same thing happens with externally balanced engines if you replace the flexplate, flywheel or harmonic dampener.

Some aftermarket replacement pistons and rods weigh about the same as the original parts, but others may be heavier or lighter depending on their design. What’s more, some piston and rod sets may be weight matched fairly close (plus or minus 2 grams) from the factory while others vary quite a bit. Consequently, if you do not weigh the parts on a highly accurate scale, you have no way of knowing how much they actually weigh or how much their weight

differs from the original parts.

Some aftermarket replacement pistons and rods weigh about the same as the original parts, but others may be heavier or lighter depending on their design. What’s more, some piston and rod sets may be weight matched fairly close (plus or minus 2 grams) from the factory while others vary quite a bit. Consequently, if you do not weigh the parts on a highly accurate scale, you have no way of knowing how much they actually weigh or how much their weight

differs from the original parts.

The Bobweight Effect All crankshafts have a target bobweight (plus or minus 2 percent typically) that approximates the weights of the pistons and rods that are going on the crank. The closer the target bobweight of the crank to the actual parts, the less drilling it takes to bring the crank into balance. Because of this, it’s important to know the approximate weights of the pistons and rods when you are buying or ordering an aftermarket crankshaft.

Balancing Basics

One of the basic goals of engine balancing is to equalize the weights of the pistons, wrist pins, rings, connecting rods, rod bolts and bearings so as to equalize the reciprocating and rotating forces that are acting on the crankshaft.

Each of the parts is carefully weighed to determine which piston and which rod is the lightest. The other pistons and rods are then ground or machined to equalize their weights to the lightest one in the set. Another trick that some engine builders use is to mix and match heavy and light pistons and rods that share the same journal to equalize the weights on each journal.

Once the weights have been measured and equalized, the rotating and reciprocating weights need to be separate from each other. The rotating weight is the big end of the

connecting rod, rod bolts and rod bearings, plus a few extra grams for oil while the reciprocating weight is the small end of the rod, wrist pin and locks, piston and rings.

After these values have been determined (for a 90-degree V8 engine), bobweights that simulate 100 percent of the rotating weight (times 2 because there are two pistons sharing the same journal) and 50 percent of the reciprocating weight (times 2 for the two pistons also share the same journal) are assembled by stacking metal weight shims. The bobweights are clamped on each rod journal and the crankshaft is then spun on the balancer.

Once the weights have been measured and equalized, the rotating and reciprocating weights need to be separate from each other. The rotating weight is the big end of the

connecting rod, rod bolts and rod bearings, plus a few extra grams for oil while the reciprocating weight is the small end of the rod, wrist pin and locks, piston and rings.

After these values have been determined (for a 90-degree V8 engine), bobweights that simulate 100 percent of the rotating weight (times 2 because there are two pistons sharing the same journal) and 50 percent of the reciprocating weight (times 2 for the two pistons also share the same journal) are assembled by stacking metal weight shims. The bobweights are clamped on each rod journal and the crankshaft is then spun on the balancer.

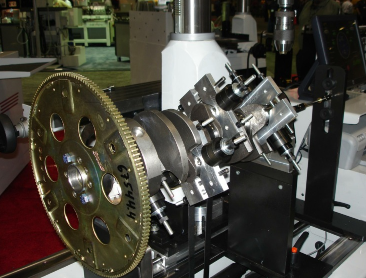

Highly sensitive motion sensors detect any wobble in the crank, and the balancer’s electronics split the crankshaft into two halves (right and left) and essentially balance each half of the crank separately (2-plane balancing).

Some balancers also compare the results of the left and right sides to see how the forces interact (3-plane balancing) before displaying the index location and amount of imbalance that needs to be corrected. Weight is then removed by drilling or machining the counterweights, or added by installing heavy metal tungsten (“mallory”) plugs into the counterweights to offset the indicated imbalance. The crank is then spun again to check the corrections that were made. This procedure is repeated as many times as it takes to achieve the desired degree of balance.

In the case of superlight racing cranks, the counterweights may be turned down so much that there isn’t enough metal to offset the bobweights. If this is the case, the crank will likely require heavy metal plugs to balance it and/or external balancing with the flywheel and harmonic dampener.

Another issue to watch out for is that some cheaply made import crankshafts may not have enough metal in the counterweights to achieve balance easily or inexpensively (heavy metal plugs are expensive). Or, the counterweights may not be positioned correctly on the crankshaft to allow proper balancing.

There’s no way of knowing this until you start to balance the crank and realize it’s way off the mark and will take a lot of work to balance it.

There’s no way of knowing this until you start to balance the crank and realize it’s way off the mark and will take a lot of work to balance it.

To reduce overall weight and cost, most crankshafts for 90-degree V8 engines have six counterweights instead of eight. No counterweights are used on either side of the center main bearing. If the crank had eight counterweights (one for each cylinder), each weight would be offset 180 degrees from its journal.

But with only six counterweights to serve this function, the counterweights are offset 135 degrees from their journals.

Some math whiz figured this out and saved the auto makers a lot of money – but also made life harder for anyone who is trying to balance a really high revving engine or one with a long stroke crank.

So racing cranks with eight counterweights are available for applications where the extra weight really doesn’t hurt from a performance standpoint, but really helps from a balance standpoint. NASCAR engines typically run in excess of 9,000 rpm for much of a race so having an eight counterweight crank helps control vibrations and harmonics at these speeds.

Weighing Your Options

When it comes to balancing “tricks” some performance engine builders will slightly overbalance or underbalance the crankshaft in an attempt to minimize vibrations and harmonics within a specific rpm range. Overbalance means adding extra weight to the bobweights when the crank is balanced, while underbalancing means using less weight on the bobweights when the crank is balanced.

For example, if you want to overbalance an engine 2 percent, you would use 52 percent of the reciprocating weight of the pistons and small rod ends instead of the usual 50 percent weight when assembling your bobweights. To underbalance the engine 2 percent, you would use 48 percent of the reciprocating weight instead of the usual 50 percent. Imbalances and harmonics in the crankshaft are transmitted to the camshaft and valvetrain by the timing chain or timing gears.

If a slight overbalance creates vibrations that offset any undesirable valvetrain harmonics, the engine runs smoother and makes more power. But if the vibrations don’t offset and amplify one another, things only get worse.

Some say that slightly overbalancing a high revving engine helps dampen harmonics that may occur above a certain rpm. Those who use this technique claim it makes an engine run smoother and makes more power. The problem is, overbalancing may or may not smooth out high-rpm power and vibrations, and it may make things worse. Many piston and rod suppliers recommend a neutral balance (the usual 50 percent of the reciprocating weight) unless an engine is really experiencing some severe high-rpm shakes. What works on one engine may or may not work on another engine because of differences in valvetrain geometry, stiffness and dynamics.

Those who swear overbalancing works typically recommend overbalancing 1 percent (using 51 percent of the reciprocating weight) if the engine revs above 8,000 rpm, 2 percent if it revs to 9,000 rpm, and 4 percent if it revs to 10,000 rpm.

By comparison, some Formula 1 racing teams underbalance their engines several percent because they have found it helps offset the second order harmonics that occur at extremely high engine speeds (up to 18,000 rpm in some of these engines!) Underbalancing is also being used in some monster drag motors with long cranks (up to 4 percent underbalance) to smooth things out at high-rpm.

The point here is that overbalancing or underbalancing essentially creates a dynamic imbalance inside the engine. The imbalance will create vibrations the same as if the engine had not been balanced correctly in the first place.

But if the imbalance is tuned for a specific rpm range, it can offset bad vibes that are hurting performance. What happens outside this rpm range in a racing engine doesn’t matter because it’s outside the engine’s normal power range.

Did You Know… Engines that run at fairly constant high rpm typically benefit most from overbalancing (or underbalancing in the case of Formula 1 engines). However, engines that have to operate across a wide range of rpms may or may not realize any benefit from overbalancing or underbalancing, depending on the dynamics inside the engine. It may help at some speeds and hurt at others.

‘Ins’ and ‘Outs’ of Balancing

Many engines such as small block Chevys are internally balanced. The crankshaft has enough mass in the counterweights to allow the rotating and reciprocating forces to be balanced by machining the crank.

The flywheel and clutch are neutral or zero balanced, which means engine balance is unaffected if the flywheel or clutch have to be replaced later.

Smallblock Fords, by comparison, are externally balanced, as are some big block Chevys (454s). This means the flywheel (or flexplate) and harmonic balancer contribute to overall engine balance and must be mounted on the crank when it is balanced to achieve proper balance. It also means the index position of the flywheel (or flexplate) on the crank must be maintained if it is removed and reinstalled so balance isn’t upset.

It also means engine balance will be lost if the flywheel (or flexplate) is replaced with another unit unless the balance of the replacement is perfectly matched to the original (which it may or may not be).

Most performance engine builders say the best way to go is to internally balance the engine (if possible) for the advantages listed above.

Removing Stress

The harmonic dampener or balancer on the front of the crankshaft may be used to externally balance the engine, but it’s main purpose is to dampen torsional vibrations in the crankshaft.

Every firing pulse twists the crankshaft, so the dampener helps smooth out the jolts to reduce stress on the crank. If the dampener fails to do its job because it is defective or lacks sufficient mass, the crank may be stressed to the point where the nose snaps off or it breaks.

Consider Cam Balancing, Too

Many people overlook camshaft balance when balancing an engine because a camshaft has a relatively small diameter (only a couple of inches) and it turns at half the speed of the crank.

Even so, a slight imbalance in a camshaft can become a significant vibration in a high revving engine – possibly enough to cause lifter bounce, valvetrain harmonics and ignition timing issues with a cam-driven distributor.

For this reason, many high-end racers are also balancing their camshafts now, too.

Article courtesy of ENGINE BUILDER magazine.