The main advantage of a loaded, unitized or complete assembly is not the cost of the part, but rather the efficiency it offers the technician and the greater effectiveness of repair it gives the customer. By packing a loaded caliper, strut, control arm or even knuckle into a job, you can create a “win/win” for everyone.

If a customer needs to have the bushings replaced on a control arm, you have options. New bushings may sell for $60 and a loaded control arm may cost $150. The labor to remove and replace the control arm might be 0.5 hours, while the labor time to install new bushings on a press might be and additional 0.5 hours. If a shop has a labor rate of $80 hour, the bushing job comes out to be $140 just to replace the bushings. If the loaded control arm is installed, the job sells for $190.

So, what does the customer and your shop get for $50? The customer gets a ball joint and a completely new assembly. Your shop gets 0.5 hours back of labor to sell on a more profitable job or to accommodate a last-minute customer.

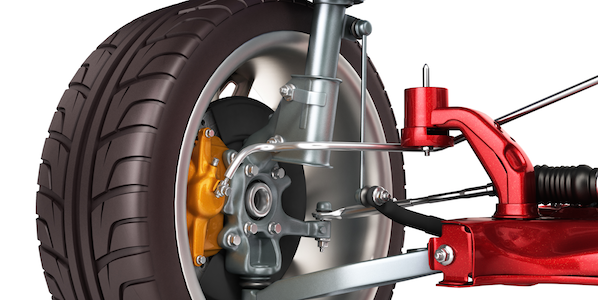

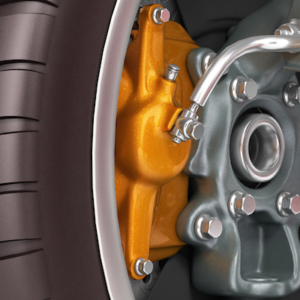

Loaded Calipers

One of the main advantages for the vehicle owner is that loaded caliper assemblies help restore the brakes to like-new condition. Not only do you get new friction, but also a professionally remanufactured caliper and properly matched hardware (shims, bushings, slides, etc.). This significantly reduces the risk of future leaks developing and prevents uneven braking or pad wear caused by calipers hanging up or dragging.

Loaded Struts

Loaded struts are typically twice the price of a strut and upper mount. Before you say to yourself that there is no way you could sell something that expensive or be competitive locally, put yourself in the shoes of your customer. If you can offer them an option that will return their vehicle to almost new condition, wouldn’t you take it even if the price was higher?

On the business side, it does not take an MBA to realize that if you can sell a more expensive part, under normal parts pricing policies, you will have more money in the bank. Also, by not having to do the strut compressor waltz, you will get the vehicle out of the bay faster so you can move on to the next job.

Loaded Control Arms

Loaded Control Arms

Complete replacement control arms and suspension links can be a more economical replacement option over replacing just the bushings. Depending on the application, the labor saved at the press can offset the price of a complete control arm. This means a thorough repair, as well as a more productive shop.

Loaded control arms can be a lifesaver if you have to deal with large and difficult bushings on aluminum components, which are not much fun to work with on a large press. New arms can also help you avoid possible corrosion issues.

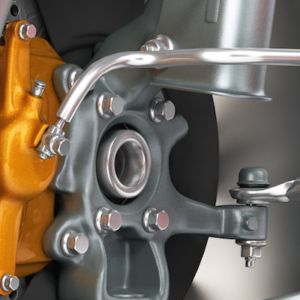

Loaded Knuckles

Loaded Knuckles

A lot of vehicles manufactured by Ford, VW and other carmakers over the past decade have been equipped with cartridge-style wheel bearings that need to be pressed into a knuckle. These bearing jobs can be difficult even if you leave the knuckle on the vehicle and use a special tool. The latest product to address this job is a loaded or complete knuckle that already has a new bearing installed.

Eliminating the need to press the bearing can save time. It can also save you the aggravation that comes from wondering whether or not you pressed the bearing in with the correct seal facing the wheel speed sensor. While you can beat flat rate, you can’t make more hours in the day. Loaded, unitized or complete components can maximize your profitability in the hours your business is open.