Vehicles Affected:

• Chrysler: 2001-’04 (JR) Sebring Convertible/Sedan, (PT) PT Cruiser, (RG) Voyager (International Markets), (RS) Town & Country;

• Jeep: 2002-’04 (KJ) Liberty, (KJ) Cherokee (International Markets); 2003-’04 (TJ) Wrangler; and

• Dodge: 2001-’04 (JR) Stratus Sedan, (RS) Caravan; 2003-’04 (PL) Neon.

Note: This bulletin applies to vehicles equipped with a 2.0L, 2.4L DOHC or 2.4L Turbo engine.

An irregular engine snapping sound may be noticed when the engine is idling in park between idle rpm and 1,400 rpm at normal operating temperature. The sound is on the upper end of the engine (cylinder head) toward the front of the engine or passenger side (right side). The sound is irregular, not periodic or harmonious. The frequency of the sound will increase with rpm. The sound is more of a higher pitch snapping noise, not a low, metallic knock.

Repair Procedure

1. Remove the cylinder head cover (refer to information available in TechConnect 9 – Engine/Cylinder Head Cover – Removal).

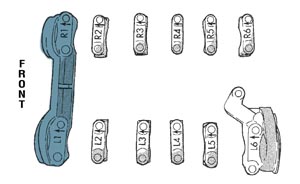

2. Remove the L2 cam bearing cap. See Figure 1.

2. Remove the L2 cam bearing cap. See Figure 1.

Note: Do not remove the L1/R1 or L6 cam bearing caps, or loosen the fasteners.

Note: Only remove one cam bearing cap at a time.

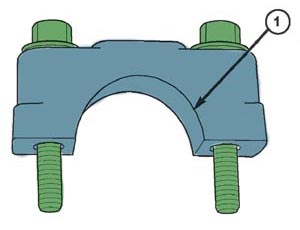

3. Lightly chamfer the two bore radius edges with a small hand file, creating a 45° chamfer 1.0 to 1.5 mm in width along the edge of each bore radius. See Figure 2.

Caution: Be careful not to scratch the bore surface of the cam bearing cap. Chamfer both bore radii.

Caution: Be careful not to scratch the bore surface of the cam bearing cap. Chamfer both bore radii.

4. Clean the part to remove any aluminum filings prior to reinstalling.

5. Reinstall the L2 cam bearing cap by loosely assembling fasteners. Prior to and during the torquing of each fastener, twist the cam bearing cap by hand in a clockwise direction, as viewed from the top of the engine. Torque the M6 fasteners to 105 in.-lbs. (12 Nm) while maintaining a clockwise twisting force on the cam bearing cap.

6. Repeat steps 2 through 4 for cam bearing caps L3, L4, L5, R2, R3, R4, R5 and R6.

Courtesy of Mitchell 1.

For more information on Mitchell 1 products and services, automotive professionals can log onto the company’s website at www.mitchell1.com.