Applied Vehicles: 2004-’06 QX56 (JA60)

Applied VINs: 2004 and 2005 Vehicles, All VINS;

2006 vehicles built before 5N3AA08(**)6N 808731

Applied Dates: Vehicles built before Feb. 10, 2006

If you confirm a “groan” or “growl” noise coming from the front brakes, replace the front brake pads with the new ones noted in this bulletin.

This noise may occur after the vehicle has been stopped several times using moderate-to-hard braking effort. The noise might then be heard during the last few feet of braking when coming to a stop. The new brake pad kit includes new pad retainers and backing shims.

Service Procedure:

1. Remove the front brake pads.

2. Inspect the rotors; service as needed.

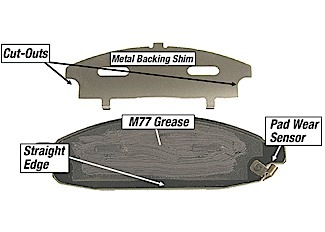

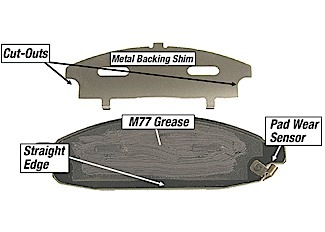

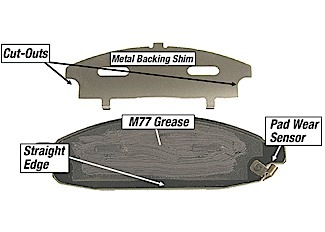

3. Prep the inboard brake pads for installation.

a. Apply a “moderate” amount of Molykote M77 grease (P/N 44003-7S000) to the back of each pad as shown in Fig. 1.

Note:

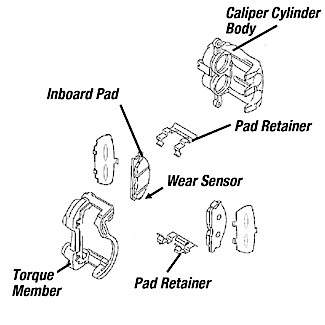

• The inboard pads have a straight edge and pad wear sensor.

• The inboard backing shims have cut-outs on the edges.

b. Install the shim and push down on it to squeeze out any excess grease.

c. Clean off all of the excess grease that squeezes out.

Caution: Don’t get any grease on the brake pad or brake rotor friction surface. Clean off any excess grease.

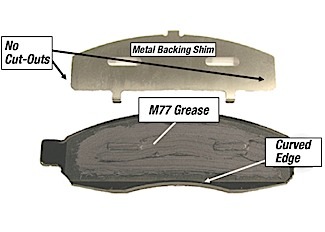

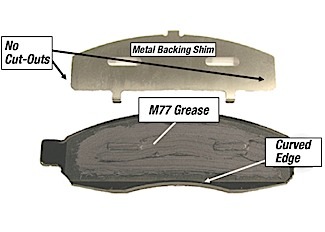

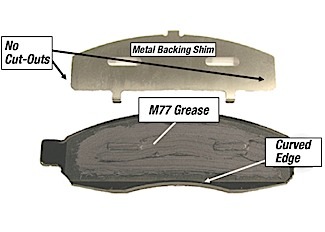

4. Prep the outboard brake pads for installation.

a. Apply a “moderate” amount of Molykote M77 grease to the back of each pad as shown in Fig. 2.

Note:

• The outboard pads have a curved edge.

• The outboard backing shims do not have

cut-outs on the edges.

b. Install the shim and push down on it to squeeze out any excess grease.

c. Clean off all of the excess grease that squeezes out.

Caution: Don’t get any grease on the brake pad or brake rotor friction surface.

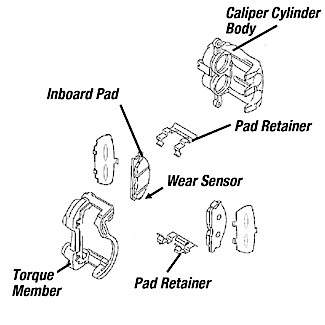

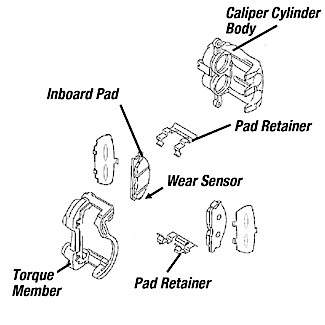

5. Install the new front brake pads and pad retainers, P/N 41060-ZC027.

• Apply a thin layer of Molykote M77 grease to the pad retainers.

• Make sure the inboard pads are installed with the wear sensors facing down — toward the ground (see Fig. 3).

6. Reinstall the wheels and lug nuts.

• Tighten lug nuts to 133 Nm (14 kg-m, 98 ft.-lb.) with a torque wrench.

• Do not tighten the wheel lug nuts with an air impact wrench.

• If you apply uneven or high torque to the lugs it may “distort” (warp) the brake rotor and hub. This could cause increased rotor runout and excessive rotor thickness variation as the rotor wears.

7. Burnish the brake pads.

a. Drive the vehicle on a straight smooth road at about 30 mph (50 kph).

b. Use medium brake pedal/foot effort to bring the vehicle to a complete stop from about 30 mph (50 kph). Adjust your pedal/foot pressure so that the vehicle stopping time is 3-5 seconds.

c. Cool the brakes down by driving at about 30 mph (50 kph) for approximately one minute without stopping.

d. Repeat a, b and c (above) 10 times to complete the burnishing process.