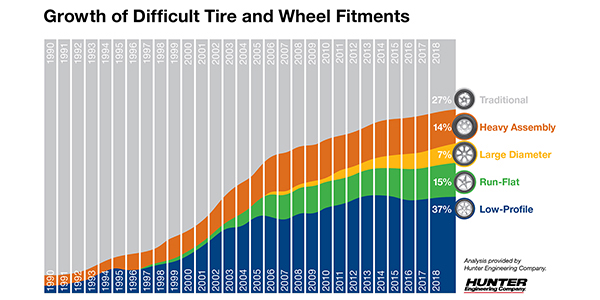

Hunter Engineering has released data illustrating difficult tire and wheel fitment trends. This data shows a significant shift in growth of difficult tire and wheel assembly fitments throughout the last 15-20 years.

Low-profile (45 series or lower), run-flat, large diameter (wheel size in excess of 20 in.), and heavy assemblies (overall diameter exceeds 30 in.) have proved to be difficult to service. Ranging across multiple OEMS, assemblies are requiring more skill from technicians using conventional tire changers and traditional balancers.

“New assemblies demand accuracy as well,” said Pete Liebetreu, vice president of marketing. “They can be sensitive to vibration and damage during service. The best equipment and best equipped shops are better able to handle these additional requirements with easy mounting, damage-free tire changers and accurate, weight-efficient, Road Force capable balancers.”

As difficult-to-service tires and wheels continue to become the norm, it is vital for automotive service providers to be equipped with the most advanced, OEM-derived technology on the market today, allowing equipment to eliminate these challenges.

Hunter Engineering’s Tire Changer Decision Guide can be found here.

For additional information, visit Hunter Engineering Company.