How much oil is too much oil for a shock or strut to leak? There have been many technical service bulletins written on the topic to help OEMs avoid needlessly replacing units under warranty. What was their conclusion? Some oil leakage is expected.

The first thing you need to realize is that no seal is perfect. The seal that keeps the oil and nitrogen inside a shock will leak tiny amounts of oil and gas from day one. As the shaft travels past the seal, some oil will stick to the shaft. We are talking about microscopic amounts of oil for every stroke. The oil eventually coats the outside of the unit.

The better the finish on the shaft and higher-quality seals means less oil will be lost during the unit’s life. In the past 20 years, shaft surfaces, hardness and seal materials have improved.

Not too long ago, the recommended replacement interval for struts was 50,000 miles. This was the average mileage when the unit’s performance started to degrade. Today, some units can go 80,000 to 100,000 miles without degrading performance.

The performance degrades because there is less oil inside the unit. With less oil, the pressure decreases inside the unit. Less pressure means that the oil can aerate and cause foam. Since foam and bubbles can be compressed and do not move the same through the valves, the unit can’t control the movement of the suspension.

The loss of oil and gas from inside the unit can be increased if the finish on the shaft is damaged. This can include small scratches caused by sand or dents due to rock strikes. OEMs have improved boots and shields to prevent this type of damage.

When the oil inside a unit heats up, it can affect the flow rate through the valving as it either thins out or becomes more viscous. Some shock manufacturers also use multi-weight oils that work like motor oils. When the oil is cold, it may flow like 15-weight oil. But, as the oil heats up, it could flow like a 20-weight.

The oil can become contaminated with debris either from the outside or internal components. In rare cases, dirt can enter the shock through the gasket that seals around the rod.

Gas is added to some shock absorbers and struts to reduce the foaming or aeration of the oil caused by cavitation as the oil passes through the valving. Over time, shocks can lose this charge of gas. If all the gas escapes, the shocks can overheat and fade.

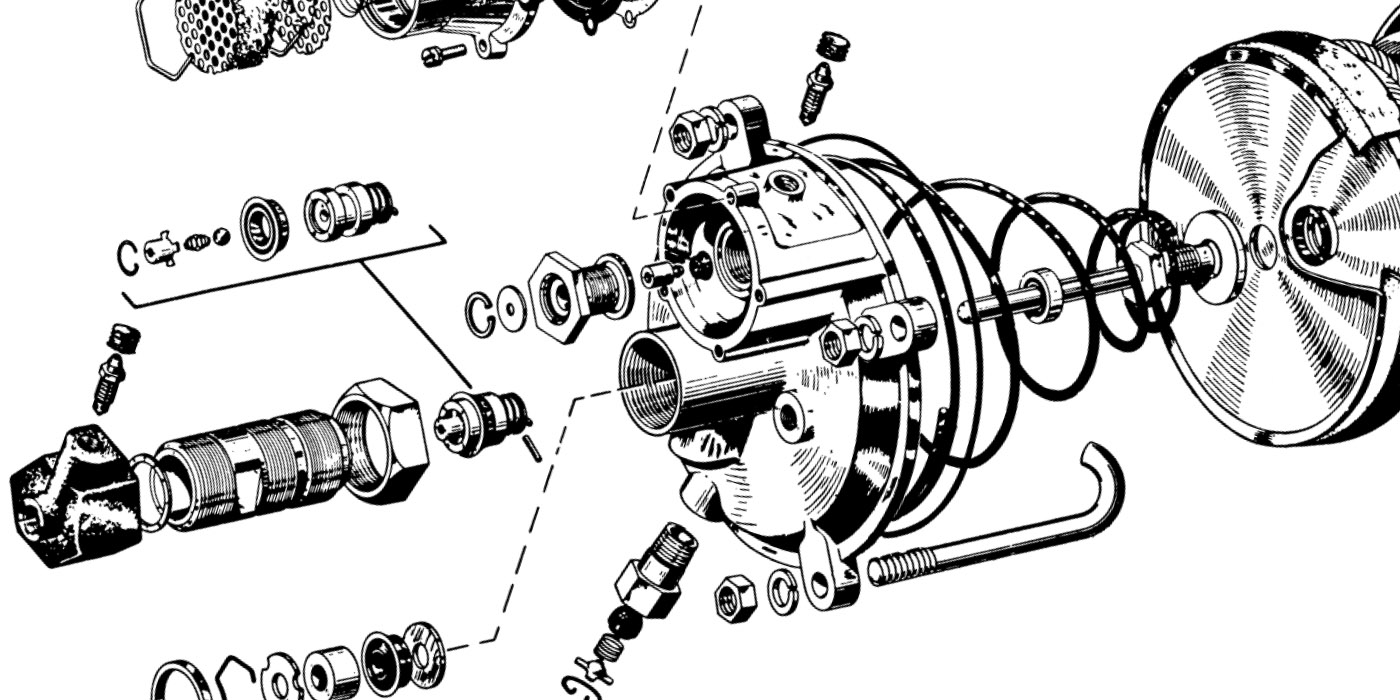

Wear can occur between the piston and tube, and, over some time, the oil will pass between the piston and tube. If the suspension bottoms out, contact between the piston and the bottom of the tube could occur. This can damage the piston and the valving. And, if the shock is worn, the springs will have to work harder and could wear out sooner, causing ride height and ride problems.

Shocks use valves to control the flow of the oil. Valves are located either in the piston or at the base of the shock. The flow rate will influence how much force it takes to move the piston. Valving works in both compression and rebound directions, and, in most shocks, both are independent rates. Like the shaft and seal, it can also wear out due to fatigue. This type of fatigue affects the metal parts of the discs and springs.

So, what is the advice for almost every oil when it comes to inspecting shocks and struts? If the oil stains are glossy appearance, it is a sign of a rapidly developing leak. But, on the other hand, if the oil has a matte or dull finish, it is a normal sign of leakage from the unit and probably should not be replaced. But, any inspection should be followed up with a test drive.