Cause

The most common cause of these problems is the bushings that connect the upper control arms to the knuckle. The internal components of the joint can degrade in as little as 40,000 miles. The problem can be corrected with SuspensionMAXX’s SSmodule (Part Number SMX-SM850). Prior to the SMX-SM850, complete knuckle replacement was the only option, which required major disassembly of the suspension.

Vehicles

2002-2006 Buick Rendezvous

2005-2006 Buick Terraza

2001-2004 Chevrolet Venture (AWD)

2005-2006 Chevrolet Uplander (AWD)

2001-2004 Oldsmobile Silhouette (AWD)

2001-2004 Pontiac Montana (AWD)

2001-2005 Pontiac Aztek (AWD)

2005-2006 Pontiac Montana SV6 (AWD)

2005-2006 Saturn Relay (AWD)

Parts and Tools

SSMod Tool (SMX-MDT)

SSModule SMX-SM850 (#l8060685 fits the right and #I8060684 the left)

Disassembly Procedure:

Note: Apply all steps to both sides of vehicle (modules to be replaced in pairs).

1. Lift the vehicle and remove the rear wheels.

2. Support lower control arms

3. Carefully loosen parking brake bracket allow inward movement creating cable clearance for upper bolt (Figure 1).

CAUTION: Do not over-loosen or remove bolts. Brake parts may become dislodged inside parking brake’s drum.

4. Remove upper thru bolt. Be sure to note bolt direction (nut forward) (Figure 2).

5. Temporarily place the parking cable below control arm.

6. Press the old module forward with SSMod-Tool (SMX-MDT) . Do not deform the knuckle (Figure 3).

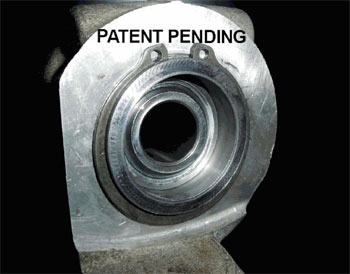

7. Thoroughly clean cylinder of all debris. Inspect for nicks or obstructions. CAUTION: Do not oversize the diameter. Clean and inspect backside for snap ring clearance — the surface must be flat.

Assembly Procedure

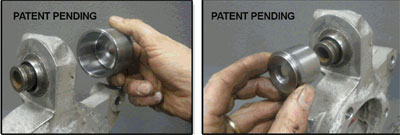

1. Lubricate the bore with anti-seize. Press new SSMODULE (SMX-SM850) with the SSmod-Tool (SMX-MDT) squarely into knuckle.

2. Install snap ring (Figure 4).

3. Clean control arm mount location using care not to remove base material. CAUTION: Inspect A-Arm mounting location for grooving or wear. If there are signs of contact from the knuckle, a replacement A-arm will be required.

4. Lubricate the SSMODULE liberally with automotive-based grease.

5. Install module extension tubes/seals, seating squarely with swivel ball. Note: Place brake cable above control arm.

6. Inspect thru bolt for rust damage, replace if needed. Re-install thru bolt as removed (nut forward). Torque to manufacture’s spec (63 ft. lbs.).

7. Tighten parking brake cable bracket to torque specifications for the vehicle.

8. Install wheel (torque to spec).

9. Perform wheel alignment.

Tip Courtesy of SuspensionMAXX. For more information go to ssmodule.com