Models

2013-2019 Cadillac Escalade

2013 Chevrolet Avalanche

2014-2019 Chevrolet Express Van

2013-2018 Chevrolet Silverado

2019 Chevrolet Silverado LD/2500/3500

2013-2018 Chevrolet Suburban

2013-2018 Chevrolet Tahoe

2014-2018 GMC Savana Van

2013-2019 GMC Sierra

2013-2019 GMC Yukon

Starting with some 2013 models, Powertrain Grade Braking is now enabled while in Normal Mode (Tow/Haul mode OFF), along with a new driver information center (DIC) message “GRADE BRAKING ON” or “GRADE BRAKING ACTIVE” when it goes active for the first time. The messages can catch the driver off-guard, and cause them to bring it to your shop. It is important to understand how the system operates so you can help explain it to the customer as a normal operation for the truck or van.

Powertrain grade braking has been available since 2009 on LD models and since 2007 on HD models, but Tow/Haul mode had to be selected. The powertrain grade braking should not be confused with “Cruise Grade Braking.”

Normal mode powertrain grade braking assists when driving on a downhill grade to help maintain desired vehicle speed by using the engine and transmission to slow the vehicle. The mode helps reduce brake temperatures and wear on the traditional braking system. Normal mode powertrain grade braking defaults to “ON” after each ignition key cycle. To disable or enable all grade braking within the current ignition key cycle, press and hold the Tow/Haul button for three seconds. No grade braking is available in Range Selection Mode (Manual Shift Mode).

For grade braking to activate it requires the driver to apply steady brake pedal pressure to maintain desired speed while driving on a downhill grade. The vehicle’s modules monitor the amount of brake pedal apply, vehicle deceleration rates, and other factors to determine if normal mode powertrain grade braking is necessary. When the feature activates for the first time that ignition cycle, the DIC will display “Grade Braking On” or “Grade Braking Active” and you will notice the transmission downshifts and engine RPM increases. At this point, if the brake pedal is released the transmission will hold the current gear. If additional engine/transmission braking is needed to help maintain the desired speed, reapply steady brake pedal pressure and additional downshifts may occur.

Normal mode powertrain grade braking will have a less aggressive transmission downshift schedule than Tow/Haul mode powertrain grade braking. Grade-braking can be exited by depressing the accelerator pedal.

DIC MESSAGES

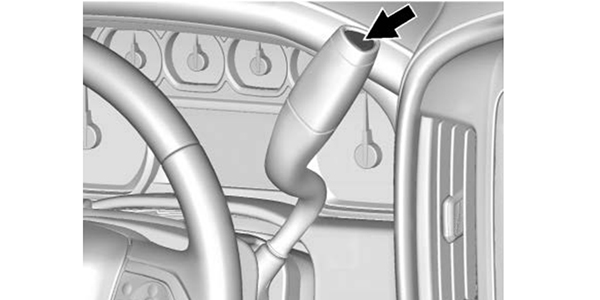

GRADE BRAKING DISABLED or OFF: This message displays when the grade braking has been disabled with the tow/haul mode button on the end of the shift lever.

GRADE BRAKING ENABLED or ON: This message displays when the grade braking has been enabled with the tow/haul mode button on the end of the shift lever.

GRADE BRAKING ON or ACTIVE: This message displays when the grade braking has been activated while driving on downhill grades. This message will only appear the first time the feature is activated in an ignition cycle. This message will not display if Cruise Control Grade Braking goes active.

On 2016 to 2019 model year Express and Savana Vans, there are no DIC messages indicating grade braking is Enabled, Disabled or Active. The grade braking feature is operational, but there are no DIC messages. Every time the ignition is cycled on, the grade braking feature is enabled. After that point, if the Tow/Haul button is pressed and held for three seconds, the feature will be disabled. If the Tow/Haul button is pressed and held again, it is enabled and so on. Remember, every time the ignition is cycled on, the grade braking feature will be enabled.