If you’ve ever cooked a meal in the kitchen, painted a wall, or installed a tile floor, you already know the importance of “the prep work”. Prep work can mean any number of things depending on the job, but more often than not it means starting with a clean space, laying out your tools or supplies so you can find them easily, and planning out the entire job so you can follow a simple workflow.

Sometimes in our eagerness to “beat the book time”, we can end up skipping steps which are critical to ensuring a long-lasting repair. Today, we’re going to focus our attention on cleaning out the fuel tank before installing a new fuel pump, and why it’s so important that we do so every time.

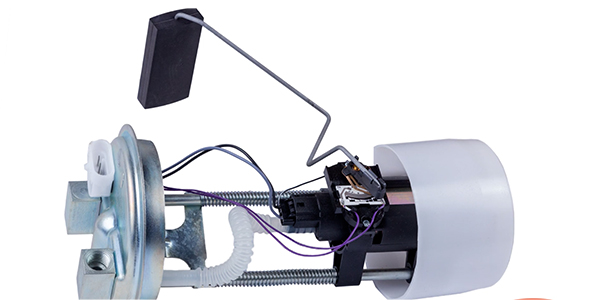

Let’s start by thinking about how a fuel pump is constructed. The first line of defense is the fuel strainer, also known as the pickup or sock. This mesh screen helps to prevent contaminants in the fuel from reaching the pump. However, if the strainer begins to clog up with dirt, debris, or rust particles, it can become an obstruction. This will restrict the amount of fuel which is pulled into the pump, forcing it to work even harder to supply the right amount of fuel to the engine. This can lead to premature failure, and a customer comeback.

Unlike those pesky leaves in your backyard pool, contaminants inside the fuel tank will likely sink to the bottom of the tank, and stay there. If those contaminants remain inside the tank, simply replacing the fuel pump will not solve the problem. Start by using a fuel extractor to pump out the contaminated fuel, then use a suitable cleaner to thoroughly clean the inside of the tank. A fuel caddy is a great tool to have on hand in your shop for this type of repair.

There are three likely sources of fuel contamination:

A faulty or missing fuel filler cap can allow dirt, debris, and other contaminants to find their way into the fuel tank by way of the filler neck.

Contaminants can also come from poor-quality or dirty fuel which is pumped into the tank from the gas station pump.

Lastly, the fuel pump itself can be a source of contamination. If the pump self-destructs, or suffers some sort of internal failure, debris could find its way into the fuel tank.

Cleaning the inside of the fuel tank is simply the best thing you can do to maximize the service life of the new fuel pump. You’re giving the pump a clean environment to operate in, and it’s going to last a long time. If you need to reuse the extracted fuel, be sure to filter it before you put it back into the tank.

This video is sponsored by Carter.