Millions of Ford Fusions were sold in the U.S. between 2005 and 2013. When it comes to alignments, it is critical to diagnose the customer first, to find out if their Fusion drifts or pulls, and then to check all of the possibilities for the complaint before throwing it on the alignment rack.

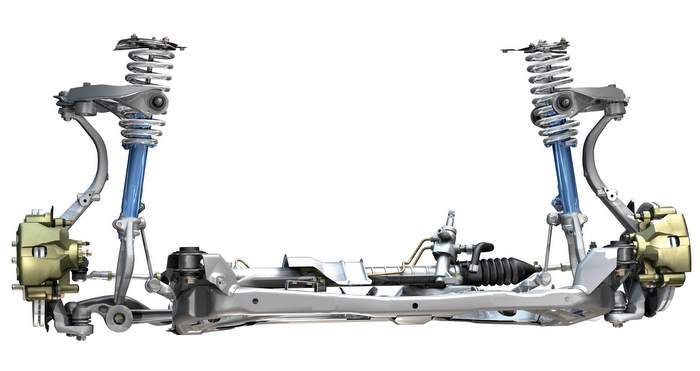

Front Suspension

The front suspension’s only built-in adjustment is for toe. To add camber adjustability, an aftermarket offset upper ball joint can be installed that can alter camber by ±1.5º.

Caster can only be adjusted by installing special upper control arms. To check the caster, raise and support the vehicle completely by the frame. This will allow the suspension and wheels to hang in the full rebound position and will provide a more accurate caster reading.

Ford has released four different control arm part numbers (two for each side) that alter the caster by ±0.4º depending on the control arm ordered. This is not a “standard adjustment,” but should be used as a last resort if the vehicle can’t be brought within specifications.

While in the area, it is a good idea to check the steering gear housing/inner tie rod for signs of wear or cuts that may have allowed water and dirt into the gear assembly. Replacement of the electronic power assist steering gear assembly might be necessary if damage is found.

Rear Suspension

The rear suspension is adjustable without any parts or kits. The toe is adjustable using a toe link; camber is adjustable by an eccentric bolt in the lower control arm.

Like all Ford vehicles with the blade-style upper control arms, the Fusion is sensitive to bushing wear in the lower links. If you see a Fusion with inner edge tire wear and negative toe, check all the bushings in the rear.

DTCs P07AE, U0415

DTCs P07AE, U0415

According to TSB 11-11-03 released by Ford, Fusions built between Feb. 1, 2011, and Aug. 16, 2011, can experience a severe amount of friction in the front lower control arms that can affect the camber and caster. A sensor in the steering system (known as an abstract steering system) will detect an acoustic vibration and generate a signal. A traction control light or steering fault may illuminate on the instrument cluster accompanied by P07AE and U045 trouble codes.

Lower Control Arm Installation

The vehicle must be in neutral and on a lift while being completely supported by its frame, allowing the wheels to hang in the full rebound position. Support the front wheel knuckle at the rear lower ball joint using a jack. In this position, you can remove the front lower arm-to-sub frame bolt, fork-to-lower arm bolt flag nut and lower ball joint nut.

The last step before replacement is to separate the front lower ball joint from the wheel knuckle. Before attempting this, place a separating item between the lower arm and outer CV joint in order to prevent the lower arm from striking the CV joint boot when free. Use a ball joint separator to do the job right, and some light tapping of the wheel knuckle might be necessary.