The Flex can have a variety of advanced driver automatic safety (ADAS) systems.

The normal alignment is changing. Control arms can still bend and bushings can degrade, causing the camber, caster and toe to change. But, modern cars not only need the angles to be in the green, but they also need to have the sensors calibrated.

The Ford Flex shares the same platform as the Ford Taurus and Explorer. The front suspension uses a MacPherson strut and a lower control arm with a large bushing at the rear. The rear suspension is a multi-link arrangement that differs little between the front-wheel-drive and AWD models.

The Flex can have a variety of advanced driver automatic safety (ADAS) systems. All models come with electric power steering and stability control. Depending on the model year and trim level, it can have a radar sensor used for collision avoidance and cruise control.

Front Suspension Adjustments

Front caster is not adjustable on the Taurus. The camber is factory adjustable by rotating the upper strut mount. By turning the upper strut mount 180 degrees, it can give .5 degrees of positive camber. If the camber is out of specification, look at other issues with control arm bushings and the ride height. The tell-tale sign of a control bushing problem is a caster angle also out of specifications.

Rear Suspension Adjustments

The rear camber and toe are adjustablefrom the factory. The upper arm is slotted, where it connects to the knuckle. At the factory, the knuckle is pushed inboard for maximum negative camber. If additional camber adjustment is needed, cam bolts are available.

Steering

The Flex uses electric power steering, for more than just assisting the driver. It can make parking easier and even correct for uneven road surfaces. The Power Steering Control Module (PSCM) and Electric Power Assist Steering (EPAS) motor are mounted together.

The steering angle is computed with position sensors on the motor, angle sensor on the column, and data from the ABS module.

The system uses an electric motor coupled to the steering rack by a toothed belt.

The PSCM uses a temperature sensor to monitor the internal temperature of the EPAS gear. This DTC appearing by itself does not indicate a fault condition in the steering system. If the system detects higher than normal temperatures, code B1D23:4B (Overheat Sensor: Over Temperature) will be set.

Diagnose all other EPAS DTCs before diagnosing B1D23:4B. Overheating can be caused by a missing heatshield, heavy loads (low-speed maneuvers) or high ambient temperatures.

An example of a heavy load would be multiple parking lot maneuvers over a short duration of time with low tire pressure or towing for long distances, followed by multiple parking maneuvers.

The presence of DTC B1D23:4B prevents the active park assist system (if equipped) from activating. If set during an active park assist event, the event is terminated, and the active park assist system is deactivated.

The electronic power steering system adaptive learning helps correct road irregularities and improves overall handling and steering feel. It communicates with the brake system to help operate advanced stability control and accident avoidance systems. Additionally, whenever the battery is disconnected or a new battery is installed, you must drive your vehicle a short distance before the system relearns the strategy and reactivates all systems.

The system is very robust, but the weak point is the wiring. The connectors, modules and wires reside low in the engine bay and are subject to water, debris and heat from the engine. Ford has issued a general service bulletin and offers an updated harnesses to correct the problem.

Collision Avoidance And Adaptive Cruise Control

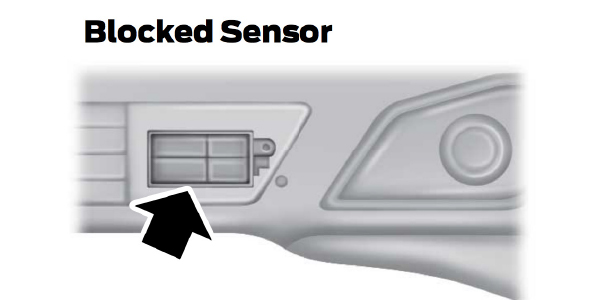

The later models of the Flex come with radar that is used for the adaptive cruise control and collision avoidance system. It is mounted in the lower-left area of the front bumper. Calibration of the radar requires the correct software scan tool and fixtures to align the radar module. The radar can cause issues and false alerts if it is covered in ice and snow or misaligned after a collision.

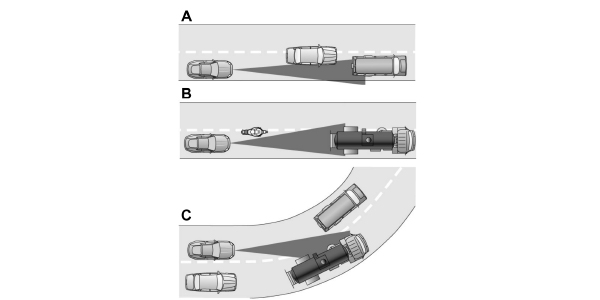

This system is designed to alert the driver of certain collision risks. A radar detects if your vehicle is rapidly approaching another vehicle traveling in the same direction as yours. If it is, a red warning light illuminates and an audible warning chime sounds. The adaptive cruise can keep a set distance from another vehicle.

The brake support system assists the driver in reducing the collision speed by charging the brakes. If the risk of collision further increases after the warning light illuminates, the brake support prepares the brake system for rapid braking. This may be apparent to the driver. The system does not automatically activate the brakes but, if the brake pedal is pressed, full force braking is applied even if the brake pedal is lightly pressed.

The biggest issue you may deal with is false activation complaints. The driver may complain about false warnings on the dash or unexpected application of the brakes. Most false activations are related to bad information from the steering angle sensor and/or radar. The best diagnostic strategy is to look for codes and data from the sensors. Small errors from the two sensors can add up to false activation. If the radar is misaligned, it can pick up vehicles too late or vehicles in the next lane.

If there is no issue with the sensors, the warning system sensitivity can be adjusted. Three possible settings can be selected by using the information display control if collision warnings are perceived as being too frequent or disturbing. Setting lower sensitivity would lead to fewer and later system warnings.