Is it the tire, suspension or steering?

pull on a vehicle typically involves more than one angle or component. How well a vehicle stays in a lane is the result of a complex equation involving the suspension, steering and tires on all four corners.

The customer’s definition of a lead/pull condition is explained by the wheel not being straight when traveling in a straight line. An engineer’s definition of a lead/pull condition is the chassis and tire conditions that require steering input to achieve travel in the desired direction. For a technician, it’s about capturing what the driver is experiencing and diagnosing if the condition meets the mechanical criteria for the complaint. When looking to cure the problem, it could be an issue with stacked tolerances of different components and systems.

But it is also physical and psychological. If a driver has to apply a constant input to the steering wheel, it causes fatigue. It makes driving unpleasant. Remember, every driver has a different threshold for a pull.

Lead/pull conditions occur at all speeds. In general, the amount of force on the steering wheel or steering angle will increase with speed. If the customer states the lead/pull problem is sporadic, then the cause could be the stability control system or electric power steering system. These systems can measure the steering angle and the direction of travel. If there is an issue with the data generated by the sensors, it will try to correct the problem when there isn’t a problem.

THE TEST DRIVE

Test driving the vehicle is critical. Just pulling the car into the alignment bay, taking readings and looking for the specification that is out of whack will typically never solve a customer complaint or car problem. It is critical to ask the customer at what speeds they experience the condition and on what type of roads. Without knowing this information, you will never solve the problem.

Many OEMs have criteria for steering pulls and if they need further investigation to determine if the OEM should pay for a warranty claim. Some manufacturers say a vehicle drift over one lane in five seconds at 60 mph qualifies for a warranty claim. Other manufacturers have weights that mount to the steering wheel. These procedures and tools take the guesswork out of determining if the driver is crazy.

TIRES

The first item to inspect are the tires. While it is not as big of a problem as it was 20 years ago, it can still seen. Today’s tires are made to higher tolerances and the decreased sidewall area can reduce the chances of a tire’s rolling circumference from causing pulls.

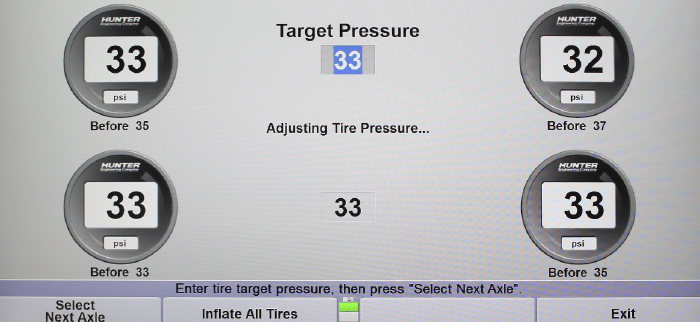

But there is one thing that remains constant: drivers not checking the inflation pressure regularly. A side-to-side difference as small as 3 psi can cause a lead/pull condition.

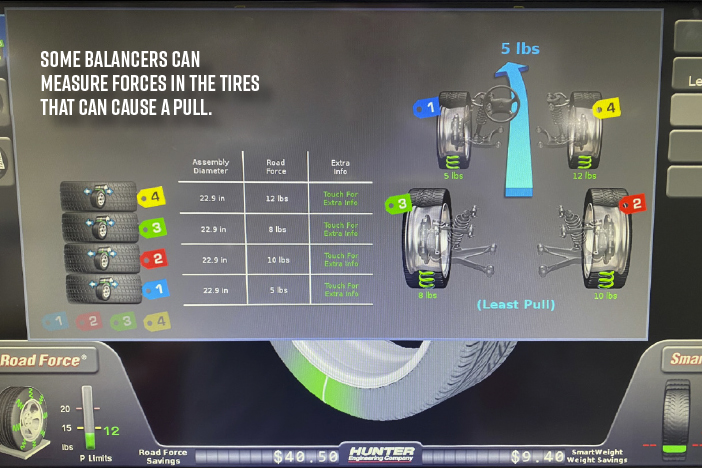

Rotating tires can give you an indication if the problem is related to the tires. If you rotate the front tires side to side and the pull is in the opposite direction, you may have found your problem. If you rotate the tires front to rear and the problem is gone, you just might have solved the problem until the next rotation. Some balancers are able to measure the “road force” of the wheel and tire assemblies. Look at the full set of tires and wheels and come up with a mounting strategy to cure the steering lead/pull.

RIDE HEIGHT

Ride height is more than a measurement to gauge the health of the springs. It is a diagnostic measurement that can be used even if you do not have the specifications or procedures. One method to measure ride height is to measure the height of the lower inboard control arm bolt and the height of the spindle or center of the wheel. Subtract the height of the spindle from the bolt height. Now compare that measurement to the other side. If the measurement is ½-in. or more off from the other side, start looking for bent parts or worn bushings. After that, look at the springs for missing coils or lackluster ride control qualities on the test drive.

The most important thing to remember is that as the suspension compresses, the alignment angles change. It is possible to set toe, caster and camber within specifications on a vehicle with lower ride height. But, as the suspension moves, the changes in camber and toe can be more severe. Both camber and toe can cause steering pulls. Also, changes in caster can change steering feel and stability.

IN THE GREEN, STILL A PULL?

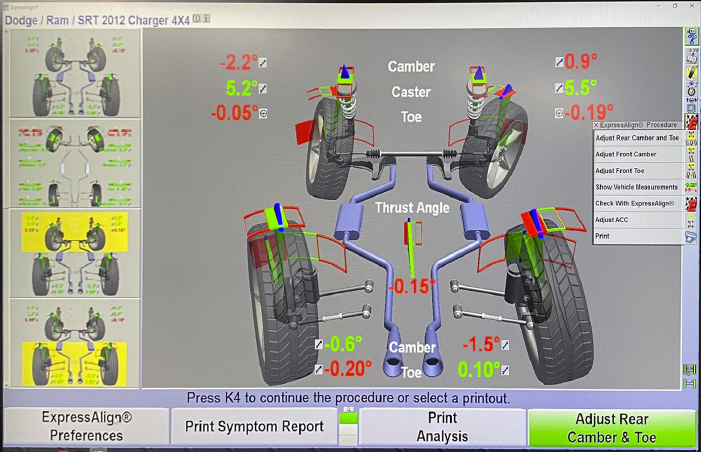

Even if all of the angles are in the green, the car may still have an alignment problem. Interpreting the angles and thinking about how an angle on one side can “add up” to trouble on the opposite side is critical for avoiding comebacks. Positive camber on one side with negative camber on the other can add up to a pull even if the specs are within tolerances. That is because +0.3 degrees on the left and -0.3 on the right can cause a pull to the right, even if the angles are green.

The other issue could be the thrust angle. The thrust angle is determined by the rear toe. Toe in the front equalizes when the vehicle is moving due to the steering rack; the rear axle can’t do this trick. It causes the thrust angle to differ from the centerline of the vehicle. The front steering angle changes to keep the vehicle going straight if the thrust angle is great enough. This results in a steering wheel that is off center when the car is going straight. A thrust angle can be hard on tires and cause uneven wear patterns.

Electric Power Steering Wrinkle

The electric power steering system measures steering wheel torque being applied by the driver to keep the vehicle in the lane. When the software detects extra effort being used, the steering assist motor adds torque in the proper direction to prevent the driver from having to make corrections to keep the vehicle on the path he selected. This active-assist reduces driver fatigue and effort and makes steering easier. The software automatically resets itself to compensate for changing road conditions or the vehicle turning on curves.

This software will compensate for a specific range of lead/pull-up to its maximum limit within a set of parameters that can prevent a motor from overheating. This type of active compensation can be disabled with a scan tool so the cause of the pull can be diagnosed.

If a customer comes to your shop with a steering pull complaint, never jump to conclusions. Before you start making changes, confirm all the angles and parts.