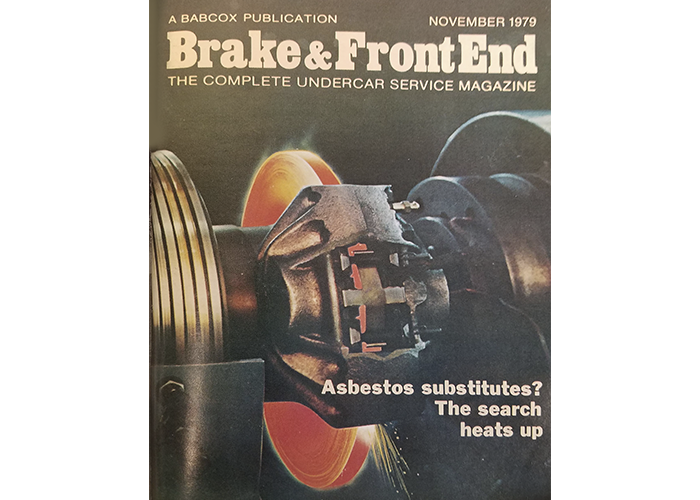

Brake Light: November 1979

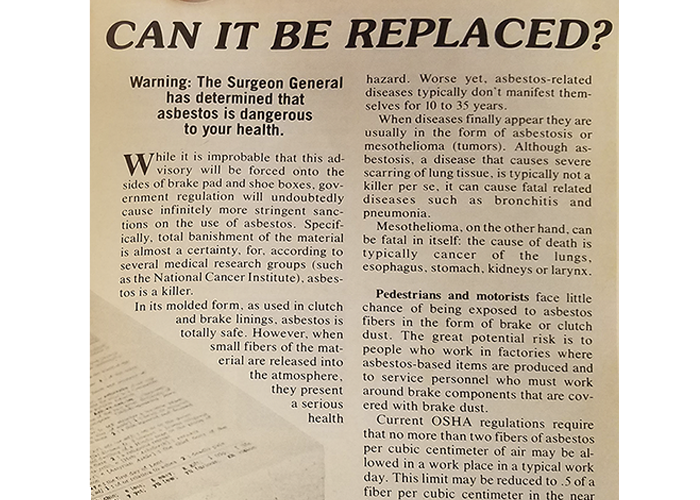

Exposure to asbestos was first discovered to be toxic in the 1960s but it was not until 1976 that a plan was enacted to phase out asbestos in brakes and other products. The fear in this industry was that an immediate all-out ban on the mineral in brakes pads and linings would lead to unsafe brakes. The complete phasing out of asbestos was to take place by 1989 because time was needed to find alternatives. Some manufacturers used Kevlar and other man-made materials – the one material that offered similar properties to asbestos was ceramic fibers. But during the slow phase-out process, brake pad manufacturers also became better at formulating semi-metallic materials leading to products that we have today.