For a lot of older technicians, the first exposure to an oscilloscope or scope was with a cathode tube monstrosity that could only look at secondary ignition waveforms. It was a great tool to identify worn point sets, spark plugs and wires. Outside of the ignition system, it did not have any other applications.

By the late 1970s, these scope machines were gathering dust in the corners of shops as electronic ignition diagnostics became very simple. The typical repair consisted of selling a tune-up that included plugs and wires. If that did not solve the problem, the shop would swap in a “know good” ignition module or coil. It was common practice to keep a few “known good” ignition modules and coils it the toolbox to perform these types of diagnostics. Ninety-five percent of the time, this solved the problem and cost the customer less than $150.

In the early 80s feedback carburetors, throttle-body injection and more advanced ignition systems with multiple coils changed how engines operated. Also, OBDI with all of its limitations was making scan tools a required for shops. But, the biggest change were new sensors that need to be diagnosed before they are replaced. The large test machine made a little bit of a comeback. Updated machines could measure the duty cycle of some solenoids, exhaust emissions and even perform relative compression tests. It also became the go-to device for diagnosing alternators with internal regulators. But, automotive technology was moving faster than then these machines. By the early 1990s, these machines were again relegated to the back of the shop.

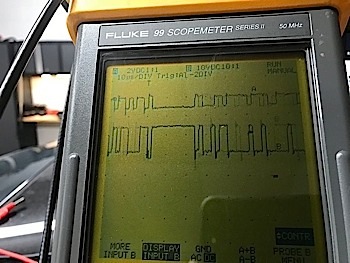

The first scopes came out in the early ‘90s these typically could display a decent waveform on a small LCD screen. Some could even store waveforms so they could be shared with other technicians. For some technicians, these shared assets replaced “known-good” parts.

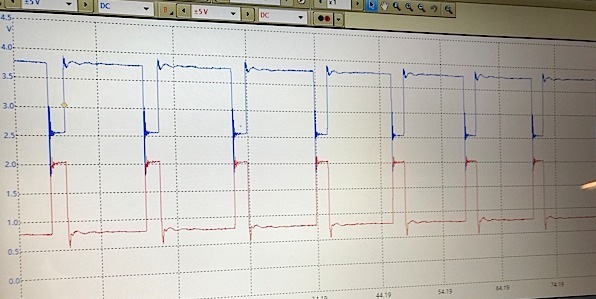

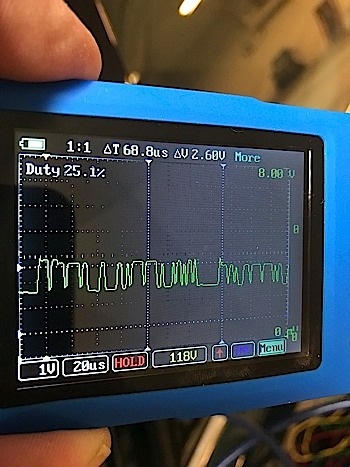

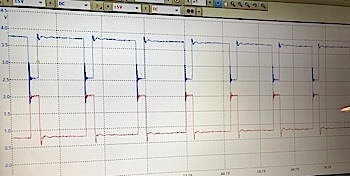

Over the past 25 years, the scope has evolved. New scopes are faster, easier to use with more automated features to capture waveforms faster. But, they all do the same thing since the 1960s, graphing voltage over time. As every year has passed, they have become faster and more intelligent on setting up scales and triggers automatically.

It still takes skill to refine the voltage scale, time and triggers to get a waveform. Being able to interpret the waveform requires time, training and most of all a source of “known-good” waveforms.

Being able to use a scope allows you to make a more accurate diagnosis faster. It is a tool that can prevent that second call to a customer advising them the initial estimate did not work. It can also be a triage tool that can save you from having to remove plugs to perform a compression test or give additional evidence if a misfire is electrical or mechanical.

Why do some technicians avoid the scope? Part of it is fear and intimidation. Some of the training I have seen either talks down to the technician or is too much about the features of the specific scope and does not tackle theory. Part of it is also not gaining experience by going out and capturing waveforms on vehicles that are not malfunctioning.