Dodge Chargers have seen quite a range of sizes and platforms since the first generation muscle cars were built in the late ‘60s. Since then, they have been built on three different platforms. The Charger name has been used on subcompact hatchbacks, full-sized sedans and luxury coupes.

Redesigned in 2011, the seventh generation Dodge Charger is the most recent. The modifications included new side scoops along both front and rear doors, as well as more angular headlights, an aggressive looking grille and improved aerodynamics. The side and rear styling cues are a throwback to the 1968-1970 models.

The Super Bee platform (called Scat Pack), built from 2012-present, included a 6.4L engine with 470 HP, four-piston Brembo calipers, slotted rotors, paddle shifters, and notably included SRT launch control features for drag racing.

The non-SRT models included four-wheel disc brakes. There were brake packages available for standard and premium. The standard brake system is referred to as “17-inch.” The premium brake system is referred to as “18-inch.”

The “17-inch” brakes (designed to fit 17-inch wheels) are standard on rear-wheel-drive models with V6 engines. They feature single-piston aluminum calipers and vented rotors in the front and single-piston aluminum calipers with solid rotors in the rear.

The “18-inch” brake package (designed to fit inside 18-inch wheels) came standard on FCA’s international models and are an optional upgrade for other models. They feature twin-piston aluminum calipers and vented rotors in the front and single-piston aluminum calipers with vented rotors in the rear. Although the rear calipers appear the same as the 17-inch system, the rear calipers used with this system feature a wider jaw to compensate for the wider vented brake rotors.

The twin-piston caliper is the same for all models, but the RWD models mount the caliper to the rear of the knuckle and on AWD models it mounts to the front of the knuckle. The Police Package models have heavy-duty brakes.

For Non-SRT vehicles, new caliper mounting bolts should be used because they come with thread locker on them. If reusing caliper-mounting bolts, be sure the threads are thoroughly cleaned and then apply new thread locking compound.

ABS Function

Popping sounds and slight brake pedal movement have been reported when the car is first started. The ABS warning lamp may also come on for about 5 seconds after the ignition is switched on. Some vehicle owners have reported a humming sound that can be heard and felt between12-25 mph. According to the manufacturer, these conditions are a normal function of ABS when the system is performing a diagnosis check.

Premature ABS cycling can occur at any braking rate and on any road surface. Furthermore, the brake indicator light (red) and ABS indicator light (amber) may come on but won’t trigger any fault codes under these conditions. Symptoms of premature ABS cycling include clicking sounds from the solenoid valves, the pump running or pulsations in the brake pedal.

Premature ABS cycling should be assessed whenever diagnosing a problem with the antilock system. Use a scan tool to detect and verify this condition. Also check for damaged wheel bearings that may cause tone wheel issues, damaged wheel bearing housings where wheel speed sensors mount, and loose wheel speed sensor mounting bolts.

Parking Brake

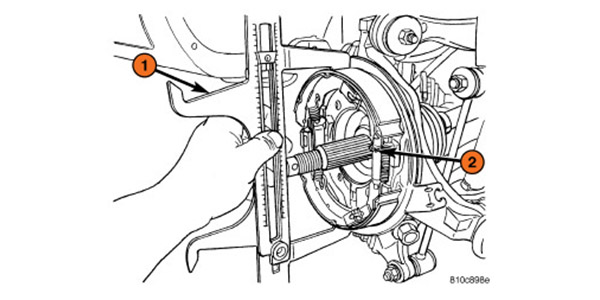

Most seventh generation Chargers require only a fine adjustment to the parking brake. However, some vehicles may need a preliminary adjustment before a fine adjustment can be made. The rear brake rotor needs to be removed if a preliminary adjustment must be performed.

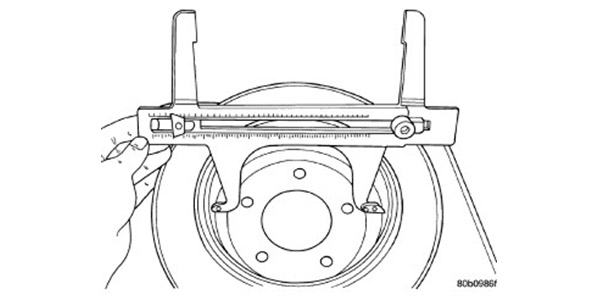

Use a brake gauge tool to measure inside diameter of parking brake drum portion of the rotor. Place the gauge over brake shoes at the widest point and adjust shoes until the linings on both parking brake shoes barely touch the edge of the gauge.

The final procedure is to go on a road test and make several stops to seat the brakes in properly. If the vehicle is equipped with the Police Package, the pads and rotors must be bedded in using a special procedure that can be performed by the police department or agency.

Brake Job Specs:

Lug nuts: 110 ft.lbs; 140 ft.lbs (Police Package)

Front caliper bracket bolts (models built before 8/2012): 140 ft.lbs.; 121 ft.lbs. (on models built after 8/2012)

Rear caliper bracket bolts: 98 ft.lbs

Front ABS wheel speed mounting screw: 97 in.lbs (8 ft.lbs)

Rear ABS wheel speed mounting screw: 71 in.lbs (6 ft.lbs)

Front caliper guide pin bolts: 44 ft.lbs.

Rear caliper guide pin bolts: 23 ft.lbs.

Minimum brake pad thickness: 1 mm (measured at its thinnest point); 0.04 inches or less.