Thanks to the increasing reliability of modern vehicles, most diagnostic technicians are seeing fewer pattern-failure driveability complaints.

Thanks to the increasing reliability of modern vehicles, most diagnostic technicians are seeing fewer pattern-failure driveability complaints.

For that reason, many techs won’t gamble expensive shop time chasing an illusive no-code driveability complaint.

Instead, many will write “no problem found” on the repair order and move on to the next vehicle.

Unfortunately, at some point in time, the intermittent, no-code driveability will either be solved or the vehicle will be traded or sold for scrap. This month’s Diagnostic Dilemma will discuss in detail how I approached the no-code, intermittent driveability complaint on three

different vehicles.

The Stalling Camry

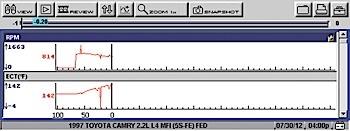

Last summer, I encountered a customer with a no-code, intermittent stalling complaint on a 1997 Toyota Camry. According to the customer, the stall most often occurred during engine warm-up or would manifest itself as an occasional hesitation at road speeds.

Although well-maintained, this vehicle had rolled up in excess of 200,000 miles. At this point, the crankshaft position (CKP) sensor had been replaced with no result.

While I don’t believe in searching for silver bullets, I do believe in doing preliminary research by consulting a professional database for technical and anecdotal case-study information.

It didn’t take but a few minutes online to determine that a faulty engine coolant temperature sensor (ECT) was causing many Camry stalling complaints.

The simplest procedure might have been to replace the relatively inexpensive ECT and let the customer drive the vehicle to verify the repair.