Corrosion Science: Bang, Burn Or Spray

Corrosion and rust are nasty problems that make repairing a vehicle difficult. Corrosion is the product of an electrochemical reaction. In a vehicle’s case, between two dissimilar metals and an electrolyte – so, an alloy wheel, a steel bearing hub and saltwater, for example.

Electronic Power Steering: Better Than Hydraulic?

Diagnosing electric power steering systems requires an understanding of voltage, current and loads. Also, a technician must understand how the modules and sensors work together to determine the level of assist.

Wheel Bearings And Locking Hubs

Automatic hubs are used on many 4×4 trucks to disengage the front wheels when four-wheel drive is not needed. Disconnecting the front wheels reduces friction and may improve fuel economy as much as one mile per gallon depending on the vehicle. A one mpg difference may not sound like much, but every little bit helps.

Brakelight: August 1952

Chet’s in Long Beach, CA, is still in business 65 years after this article was printed in Brake & Front End. Chet spent $18,000 in 1952 to build the shop — the equivalent of $163,000 today.

Springs: The Foundation Of Stability

When a wheel reacts to a bump or body motion, the spring is compressed and then releases the energy. During this cycle, the steel of the spring will compress, and just a little bit of life is taken out of it. It’s not the amount of travel that matters, but the frequency of the cycles.

Upgrading Brake & Front End

Earlier this year, we upgraded Brake & Front End’s website. We completely redesigned the site to make it more mobile phone- and tablet-friendly. Now, it is easier than ever to view past and present digital issues of Brake & Front End, renew your subscription and find technical articles on the fly.

How Quick Fixes Can Lead to Long-Term Problems

Once in a while, some of these in-the-ditch repairs truly are born out of a roadside emergency, but I tend to believe that even these quick fixes could be avoided with a little bit of proper maintenance know-how. The problem is that some people like to tackle repair work themselves regardless of their repair acumen.

Building Brake Lathe Labor Sales

Many automakers are putting more “meat” on rotors compared to just a decade ago. Also, OE ceramic brake formulations are minimizing rotor wear due to less aggressive formulations that transfer a layer of friction material to the rotor. This means that rotors are lasting longer and seeing two or more sets of pads.

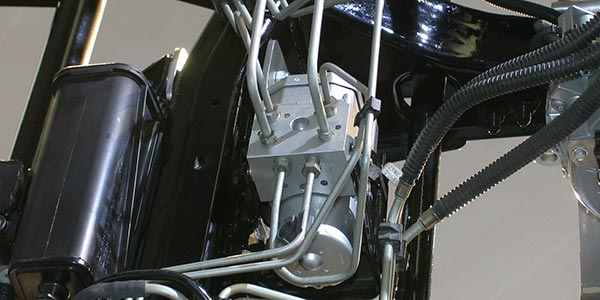

Failed Brake Booster Seal Causes Master Cylinder Leak

Chronic master cylinder failure due to fluid leaking past secondary seal in the master cylinder bore. A defective master cylinder pushrod seal in the power brake booster allows vacuum to draw fluid past secondary seal of the master cylinder.

GM Tech Tip: Trailer Wiring Damages Body Control Module

GM cautions not to splice in trailer light wiring into the factory wiring harness when preparing for trailer towing on Acadias, Enclaves, Outlooks and Traverses. On these vehicles, the circuits for stop lamps/turn signals, tail lights and the lighting grounds are controlled through the Body Control Module (BCM).

Honda Accord With ABS Codes

This system will set codes when there is high resistance to the ground. Following the diagnostic tree in this case will have you replace the ABS modulator, when in most cases it can be repaired by cleaning the ground G203.

Brakelight (August 1952)

The “Pull a Wheel!” campaign from the 1940s and 1950s played a critical role in stressing the complete inspection of brake systems. Most vehicles of this period had drum brakes.