This 2002 VW MkIV VR6 GTI was relatively unmodified from stock, which is rare these days as most of them have a multitude of aftermarket parts that may or may not perform as intended. With nearly 160,000 miles, it had a few hiccups in the first few months, namely the intake cam phaser for the VVT system. One thing we were not shocked about was the suspension. It was original and it was completely worn out. The body wallowed so much during cornering it felt like the sway bar was broken or disconnected.

There are several ways to restore and upgrade a suspension. Engineers spend a lot of time tuning the springs and valving of the suspension to give an acceptable ride and handling characteristics to a broad audience. But the engineers also have to work within the constraints of the corporate accountants. Some aftermarket suspension components are improvements on the stock parts.

A “phase one” option might be better struts and shocks paired with springs that are stiffer and lower the original suspension for both performance and cosmetics. These can improve the ride without compromising comfort. Some of these performance struts use better valving and construction over the original units.

Upgrading to coilovers gives the vehicle’s owner more adjustment for performance driving and track days. Before the coilover kit is even unboxed, be sure to inspect bushings, ball joints and entire suspension. The customer may think they need an upgrade when the reality is all they need is to repair the stock suspension. Also, stiffer springs and increased dampening forces are going to make a worn suspension bushing that much worse.

One of the most overlooked upgrades is sway or anti-roll bars. These act as a third spring that is only active when the vehicle is cornering. An anti-roll bar ties the body and suspension together, so the vehicle corners flatter. The bars improve the dynamic angles of the suspension and maximize the footprint of the tires.

The best part of sway or anti-roll bars is that they do not change the ride quality of the vehicle in a straight line. Larger diameter bars with adjustable links are available for popular applications and complement both lowering springs and coilover kits. But many customers would instead put money into coilover kits that only improve the cosmetics of the vehicle but do not improve the overall handling of the car.

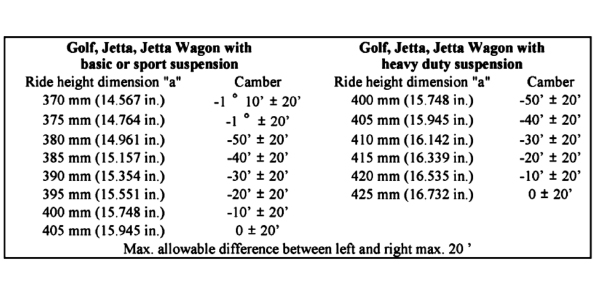

Part of the initial inspection should be measuring the original ride height. With this generation of the GTI, the ride height is measured from the center of the wheel to the bottom of the wheel opening. Volkswagen in their service information include charts that list how changes in the stock ride height change camber. Looking at the original specifications can give you a base line for the final setup.

The customer needs to be aware that what they can gain in looks and performance comes with the price of uneven tire wear and ride comfort.

Before installing any coilover kit, it’s a good idea to double check that all of the pieces are in the box. These coilover kits seldom include parts that can help adjust the caster and camber after the vehicle has been lowered. The vehicle may need cam bolts, adjustable upper strut mounts or control arm bushings.

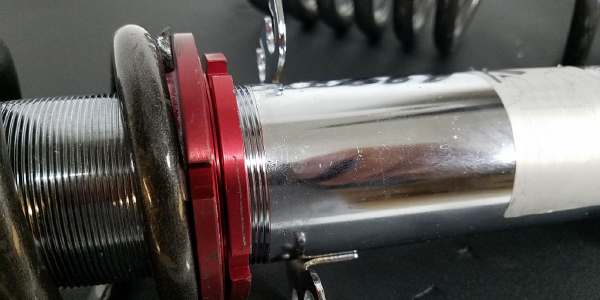

There is a fairly large adjustability range so some technicians recommend counting threads to a set height on both sides. You will also want to check the valving and set them to the softest setting and work towards the optimal stiffer setting.

Progressive springs give the car an aggressive stance without sacrificing ride quality. Unlike some constant-rate lowering springs that are stiffer all the way through the range of compression, these will get progressively stiffer as the coil compresses during hard cornering.

The spring perch has an adjustment ring on top that is adjusted with a special wrench provided in the kit. The bottom ring locks it down. Don’t tighten the bottom ring all the way down because you will want to adjust the spring height or corner weights after the car hits the ground.

You will need to install the strut bearing, mount and taper nut and then torque it down with a torque wrench to 44 ft/lbs. for this application. If your stock hardware is still in good shape, you can go ahead and reuse it. But since the suspension is apart, now is the time to install new bushings and upper strut mounts. This can save you the hassle of the customer coming back and complaining of a knocking noise.

The rear shocks are very simple to replace with the coilover upgrade on this GTI. You can reuse the stock strut mount or install a heavy-duty mount if you prefer. We will install a heavy-duty mount since our car has high-mileage and the rubber is likely worn out.

We will keep the stock bump stop but may have to cut it to fit. We will also adjust both rear spring perches to the same static height and leave it unlocked for further tuning when the car hits the ground.

When the car hits the ground we will measure from the top of the rim to the top of the fender and compare against our stock measurements. It is also a good idea to go for a quick test drive so the new springs and suspension components can settle. Before you leave the bay, turn the steering wheel lock-to-lock to make sure there is not any binding.

In our case, we don’t want to go too low since we drive it on streets in the Midwest filled with potholes and uneven pavement. For track days, we will lower the car a few turns on the spring perches and adjust the rebound.

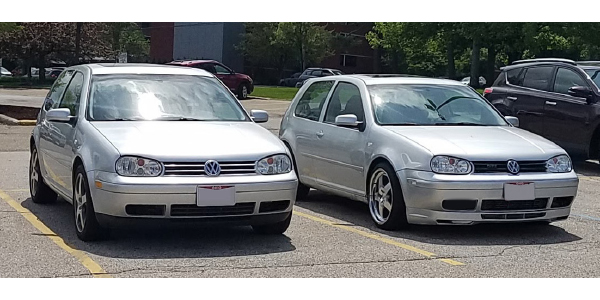

The final outcome from a stock stance compared to a GTI with coilovers is impressive. It looks like a completely different vehicle. Once we have the car set to the ride height we want, we will have it aligned and check our bump steer to make sure we don’t have any strange movements during cornering.