Independent rear suspensions are starting to become the norm on not only cars, but SUVs of all sizes. The first advantage of an independent rear suspension is ride. The second advantage is handling.

When you are looking up at one of these from under a lift, keep in mind that alignment angles and the condition of suspension are all connected in order to give the best possible ride, handling and tire wear.

The Basics

A vehicle’s weight, center of gravity, height and dimensions will influence the amount of weight transfer. The amount of weight transferred equals the vehicle’s weight times the center of gravity height, times the lateral or fore-and-aft force coefficient (expressed in g force), all divided by the track or wheelbase dimension expressed in inches.

Weight transfer can be reduced by lowering the center of gravity height, by reducing the total car weight, or by increasing the car’s track or wheelbase width. Moving the wheels further apart works because it is expanding the base that is supporting the center of gravity. This design philosophy can be seen when comparing the different designs of the Ford Explorer over the past five years. Ford might have said that widening the track for 2003 gave more interior room for a third row seat, but it really made it more stable.

Weight transfer happens during all maneuvers and for all drivers, from aggressive teenage drivers to senior citizens. Most crossover SUVs experience and deal with weight transfer a little bit differently than their car platforms.

When a driver hits the brakes and turns the steering wheel, a variety of things happen. When the brakes are applied, weight is transferred to the front wheels, and the nose of the vehicle dives and the rear may rise up. When the driver turns the wheel, weight is transferred to the outside front wheel and the body tilts to that side. As the driver returns the steering wheel back to center and accelerates out of the turn, weight is transferred to the rear and it squats down.

To be a better technician, it is critical to look at these events from an alignment, steering and chassis perspective. Also, you must look at it from a parts perspective.

Dynamic Angles

Alignment angles are not static. This is a critical concept that the undercar technician must understand. When a vehicle is on the alignment rack and the angles are measured, it is only a small snap shot. Sometimes it is an incomplete picture that the technician needs to complete with a careful inspection and taking other measurements.

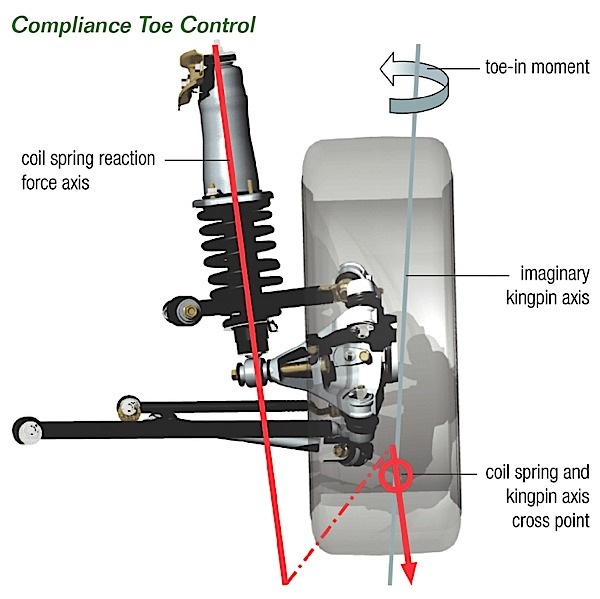

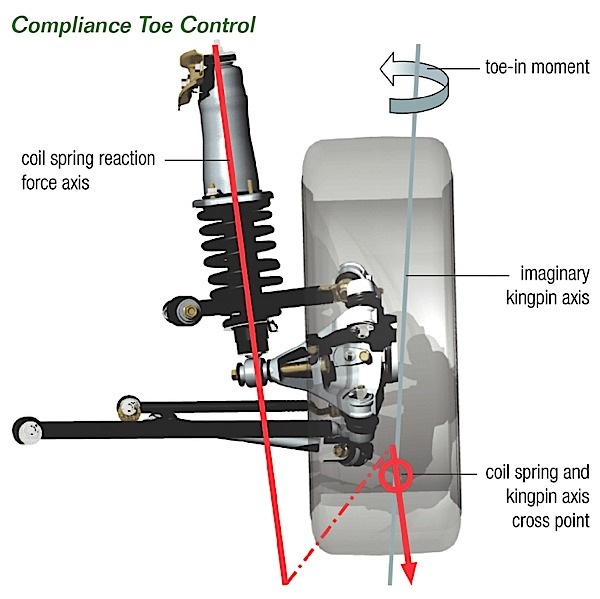

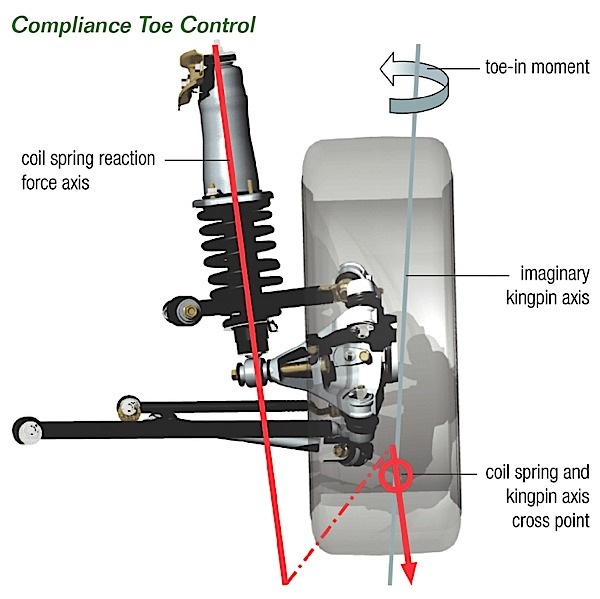

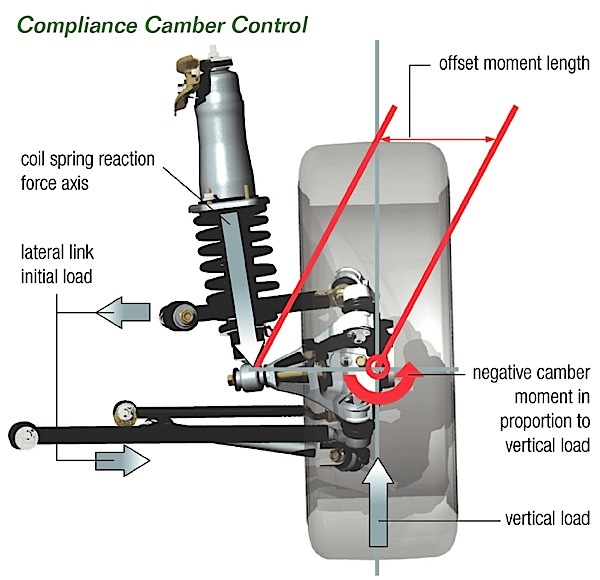

The geometry and pick-up points of a suspension change in relationship to the road as the vehicle’s pitch and yaw changes. Also, angles like caster, camber and toe influence each other as the driver turns the steering wheel. Another factor is flex, or compliance, in the suspension and steering system. If a bushing is soft, it will compress and effectively change the suspension pick-up point. If a steering rack bushing is worn, the rack could move and induce bumpsteer and maybe give the driver an uncertain feel. Wheel bearings and hub units that have too much play can cause changes in toe and camber. If more than one component has too much play, the tolerances could stack up and lead to a wild ride.

Some of these terms and concepts, like weight transfer and contact patch, you may have only associated with race cars. But, on today’s road vehicles with sophisticated suspensions, these terms are coming off the track and onto the road.

To understand the dynamic side of suspensions and steering, it is critical to first understand the weight transfer and how it interacts with the tires. These concepts can then be applied to the angles when the vehicle is in motion.

Suspension and Weight Transfer

Suspensions are designed to do more than simply keep the passengers more comfortable. The forces of weight transfer have to be absorbed or taken up by the suspension system, otherwise they will be quickly expended at the tire contact patch and could result in a sudden loss of adhesion.

Transferred weight is absorbed and dampened by the springs, shocks and sway bars. These components are tuned to give the best possible tire contact patch, while still giving the occupants a comfortable ride.

Geometry

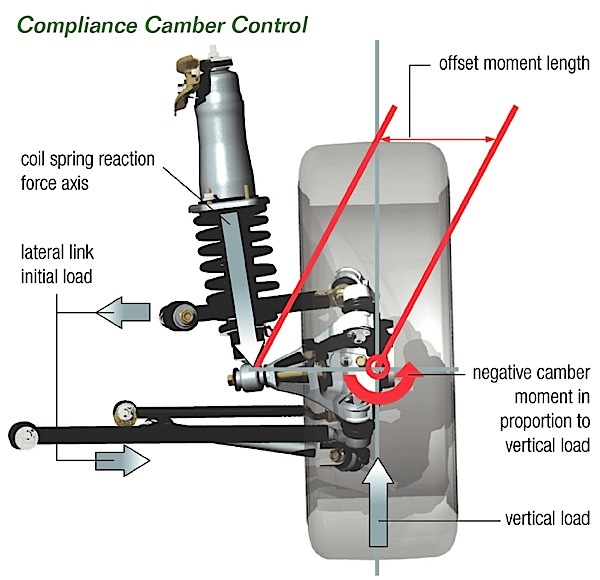

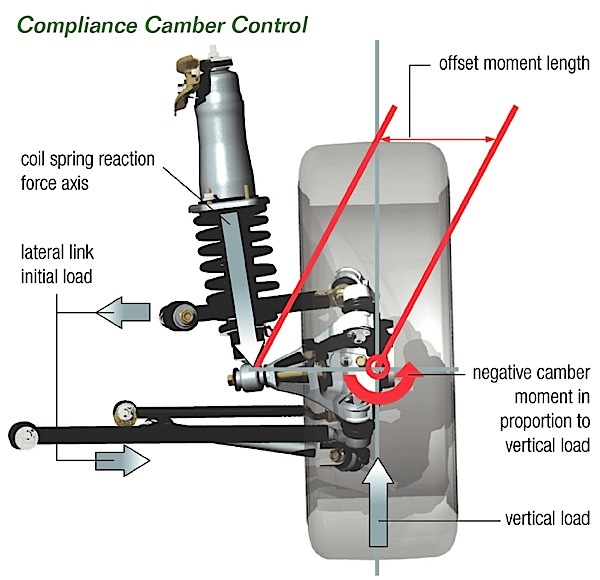

While the suspension is absorbing the forces of weight transfer and transferring it as a controlled vertical load to the tire, the control arms, links and related components are working to maximize the geometry to give the best possible contact patch as the ride height and body attitude changes.

Now that we have a solid understanding of weight transfer and tire performance, it can now be applied to a vehicle’s suspension and steering system.

When a vehicle is engineered, even before the first production prototypes are built, the suspension, steering systems and chassis are tested on a computer. The testing will “virtually” measure the suspension angles under the full range of motion. Also, it will take into account dynamics, like weight transfer and body roll.

From this information, the engineers will tune alignment settings. These computer models determine the specifications and tolerances you see on an alignment console. This is a snap shot of the static settings for that moment in time when no outside forces are acting on the vehicle.

Dynamic changes in camber can be difficult for some technicians to visualize. At speed, in a corner, the car’s body rolls (leans) to the outside of the corner. This lean and change in ride height is used by the suspension to change the camber to maximize the contact patch at that moment.

Wheels do not move straight up and down without any changes in camber. Trailing arms and suspension links move in different radiuses and arcs that affect camber. To make this easier, stick your arm out and move it up and down. Notice, it does not move in a straight line. Instead, it travels in a circle or arc. Now, just move your arm at the elbow. Notice that it travels in a tighter arc with a shorter radius. The same is true for control arms, tie rods and other suspension links. Engineers use this effect to induce dynamic camber.

On some of the BMW SUVs like the X5, the rear camber is -1.8º. This angle can change dramatically (along with the toe) under braking, acceleration and loads. These changes in the angles give the vehicle better stability. But, the angles also optimize tire wear.

The dynamic camber change works well if the vehicle is in proper working order. If the ride height is wrong, static alignment angles are out of spec, or suspension components have too much play in them, the whole geometry can make the car uncontrollable. This is why worn shocks, struts and springs could lead to longer braking distances and diminished handling. Also, if a vehicle has too much camber, it could diminish the braking ability by altering the contact patch.

Combining Camber and Caster

Camber is influenced by caster when the steering wheel is turned. This relationship is called camber roll. Caster in a spindle will cause the hub and wheel to move up and down as the steering wheel is turned. This is why it is important to keep the steering wheel straight when making a camber adjustment.

If the spindle moves downward due to caster, camber moves in the positive direction. If the wheel moves upward due to caster, camber will move in a negative direction. This effect can help to improve handling, while allowing a very neutral camber specification.

Having a grasp on what happens to alignment angles and chassis dynamics when a car is braking and turning is critical in completing the total alignment and steering system picture. This understanding of what happens when the vehicle leaves the alignment bay can help you to diagnose problems faster and make more alignment-related sales.