One of the most difficult clutch-related problems is chatter. Chatter is sometimes difficult to diagnose because it has many root causes, and some of them may not seem related at first.

Chatter can be detected as a pulsing or a grabbing sensation that resonates into the vehicle cabin and originates from the driveline or chassis/suspension.

The driver may complain that the vehicle is hard to maneuver because the entire vehicle is “bucking or jumping.” This will be especially evident while parking in tight spots, leaving from a traffic light or while trying to back up a trailer. Chatter is most evident when engaging the clutch or launching the vehicle. The driver will sense this at any contact point they have with the vehicle, such as the seat, steering wheel or floor of the vehicle.

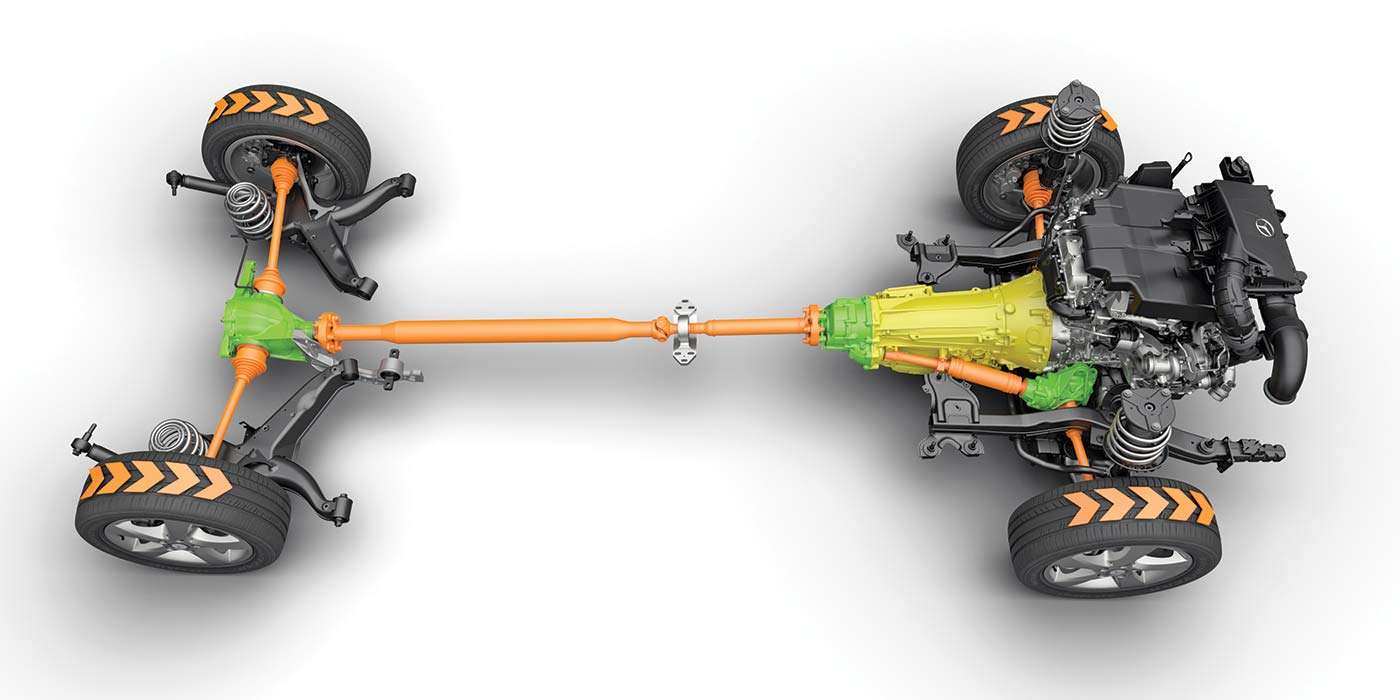

Chatter has two primary origins: within the bell housing or the suspension and/or driveline.

Chatter from the bell housing:

1. Contamination by any lubricant will cause an uneven coefficient of friction on the disc friction material that can cause grabbing and lead to a chatter condition. Contaminated friction material may result from:

• Grease or oil during installation.

• Excessive lubrication on the input shaft spines.

• Leaking rear engine main seals or transmission input shaft seals.

2. Any condition that causes the disc to be clamped unevenly between the clutch and flywheel. This could be caused by:

• Damaged drive straps on the clutch (using the clutch to brake the vehicle).

• An improperly machined flywheel (too much lateral runout).

• A warped disc (transmission not properly supported during installation).

• A warped clutch cover (tightened using impact wrench vs. evenly hand-tightened using a torque wrench).

• Glazed friction material (slipping, excess heat).

Chatter from the suspension or driveline:

While the clutch gets blamed for chatter most of the time, the suspension and driveline are often the root cause of chatter.

Keep in mind that the driveline and suspension must work in concert to transmit power/torque to the drive wheels. Any component that is loose or worn can create a frequency that the driver will feel as a chatter condition, such as:

• Worn or damaged universal or CV joints.

• Worn or broken engine/transmission mounts.

• Loose crossmember.

• Worn suspension grommets.

• Weak/broken springs.

• Worn torque damper on transverse mounted engines.

• Improper driveline angle, suspension modifications or lift kits.

All of these areas need to be inspected to determine and eliminate the root cause of chatter.

One of the main causes of chatter is installation error.

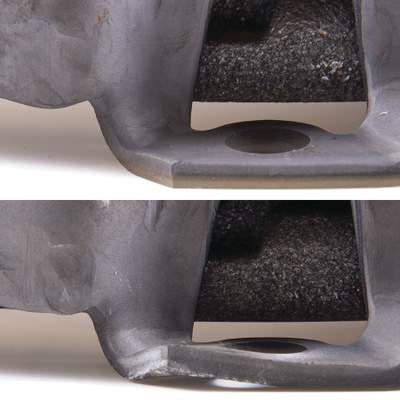

• The clutch must be torqued down evenly against the flywheel. Failure to do so may cause distortion of the stamped steel cover of the clutch (see Fig. 1). This, in turn, leads to uneven clamping of the pressure plate and contributes to a chatter condition. It’s recommended that the flywheel is resurfaced or replaced before the installation of a new clutch assembly.

• Important: Always use a torque wrench and tighten the clutch bolts by hand using a calibrated torque wrench in a star or cross pattern. This will ensure that the stamped steel clutch cover will not be distorted by the powerful diaphragm spring, especially in diesel truck applications.

• A clutch that has been tightened unevenly will clamp unevenly and display “hot spots” on its surface (see Fig. 1). This is visible after teardown for a clutch chatter complaint.

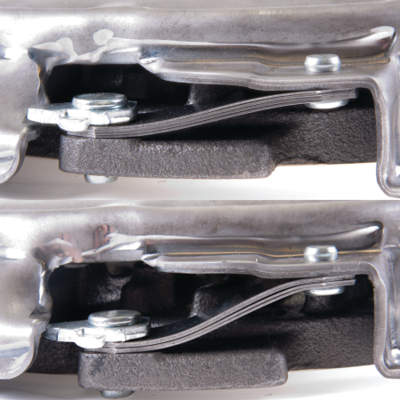

Another main cause of chatter is driver-related:

• Using the clutch to help slow the vehicle can bend the clutch drive strap and cause uneven clamping of the pressure plate and create a chatter condition (see Fig. 2).

• To avoid this situation, downshifting the transmission to slow the vehicle must be done gently. The vehicle brakes should be used to slow the vehicle down instead of the transmission.

Courtesy of Schaeffler Group USA.