The fifth-generation Buick Regal might seem like an easy car to repair on the surface when the pads need replacement, but if you assume that this is just another Buick, you could quickly find yourself in trouble.

Parts

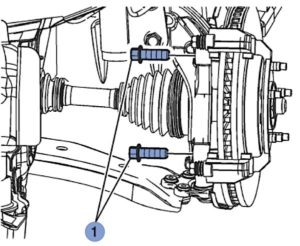

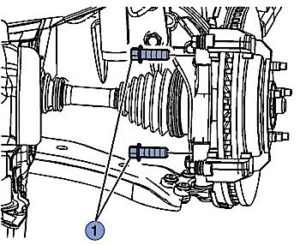

There are two brake packages for the Regal. Base models have a single-piston caliper in the front. High-performance models (GS) feature the J64 brake package that uses a twin-piston caliper in the front and a different pad. The ABS/ESC system also has a different calibration. For the GS model, Buick introduced the HiPer strut to correct the geometry problem that causes torque steer. The HiPer strut changes the SIA, or “king-pin angle,” so the angle to the tire’s centerline is less. They do this by placing two ball joints on the end of the strut.

Torque Angles

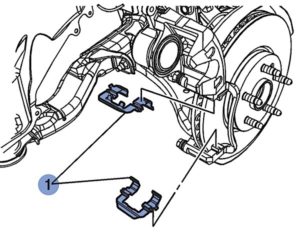

In order to reinstall the caliper bracket, you need a torque angle gauge and two new caliper bracket bolts. The bolts are torque-to-yield (TTY) fasteners that stretch. TTY fasteners are mounting fasteners that are torqued beyond the state of elasticity and, therefore, undergo plastic transformation. This causes them to become permanently elongated. The wheel bearing hub units also use TTY bolts to hold the unit to the knuckle. If you do not use the correct procedure or reuse the old bolts, the fasteners could fail. You need to tighten the front caliper bracket bolts to 150 Nm (111 lb ft) and turn the bolt 45 degrees, followed by another 15 degrees. The rear caliper should be tightened to 100 Nm (74 lb ft) and the bolt should be turned 60 degrees.

In order to reinstall the caliper bracket, you need a torque angle gauge and two new caliper bracket bolts. The bolts are torque-to-yield (TTY) fasteners that stretch. TTY fasteners are mounting fasteners that are torqued beyond the state of elasticity and, therefore, undergo plastic transformation. This causes them to become permanently elongated. The wheel bearing hub units also use TTY bolts to hold the unit to the knuckle. If you do not use the correct procedure or reuse the old bolts, the fasteners could fail. You need to tighten the front caliper bracket bolts to 150 Nm (111 lb ft) and turn the bolt 45 degrees, followed by another 15 degrees. The rear caliper should be tightened to 100 Nm (74 lb ft) and the bolt should be turned 60 degrees.

ABS/ESC/TCS

The Regal is equipped with a TRW EBC450 brake system. The electronic brake control module (EBCM) and the brake pressure modulator valve assembly are serviced separately. The brake pressure modulator valve assembly uses a four-circuit configuration to control hydraulic pressure to each wheel independently.

The dynamic rear proportioning system is a control system that replaces the mechanical proportioning valve. Under certain driving conditions, the EBCM will reduce the rear-wheel brake pressure by commanding the appropriate solenoid valves ON and OFF. The system will change the proportioning as the vehicle slows. This is done to control the attitude of the vehicle and makes for a smoother stop.

Electronic Parking Brake Control Module Description

The Regal has an electric parking brake switch in the center console, which takes the place of the manual parking brake system, the foot pedal, and the release handle. In case of insufficient electrical power, the electric parking brake cannot be applied or released. The system also adjusts the rear parking brake.

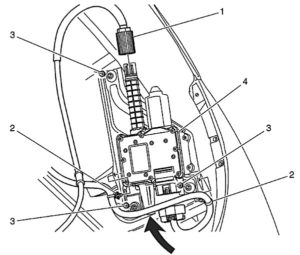

The parking brake control module has an internal motor, apply actuator, release actuator and temperature sensor. The parking brake control module also contains the logic for applying and releasing the parking brake when commanded by the park brake control switch.

The parking brake control module has an internal motor, apply actuator, release actuator and temperature sensor. The parking brake control module also contains the logic for applying and releasing the parking brake when commanded by the park brake control switch.

When the parking brake control module receives a signal from the switch, the internal circuit board temperature is checked to verify it is within operating range before the control module performs the requested operation.

The electric parking brake can be applied any time the vehicle is stopped or in motion. The electric parking brake is applied by momentarily lifting up on the park brake control switch. The red park brake light will momentarily flash while the parking brake is being applied. Once fully applied, the red park brake light will turn on. If the electric parking brake is applied while the vehicle is in motion, a chime will sound and the message “Release Park Brake Switch” will be displayed.

If the red park brake light is flashing, the electric parking brake is only partially applied or released, or there is a problem with the electric parking brake. The message “Service Park Brake” will be displayed.

To release the electric parking brake, turn the ignition switch to the ON or RUN position, apply and hold the brake pedal, and push down momentarily on the park brake control switch. When the electric parking brake is released, the red park brake light turns off.

The electric parking brake can be used to prevent rollback for vehicles with a manual transmission when on a slope. In a situation where no rollback is desired, an applied electric parking brake will allow both feet to be used for the clutch and accelerator pedals in preparation for starting the vehicle in the intended direction. In this situation, perform the normal clutch and accelerator actions required to begin moving the vehicle.

If the electronic parking brake control module is replaced or if there is a concern with either low pedal, noise or the brake is not holding, the module can be calibrated with or without a scan tool.

Calibration without Scan Tool

1. Ignition ON, apply and hold the brake pedal.

2. Push and hold the electric parking brake switch down for 5-6 seconds.

3. Release the electric parking brake switch.

4. Momentarily push the electric parking brake switch down.

5. Remove the EPB MODULE fuse and reinstall.

6. Apply the electric parking brake.

7. Release the electric parking brake.