At the start of World War II, Japan occupied the rubber plantations in the Dutch East Indies. This cut U.S. manufacturers off from the largest sources of natural rubber to make tires and products for the war effort. The U.S. solved the problem using rationing, recycling and lowering the speed limit to 35 mph. Another way to save rubber was to make sure brakes were in working order.

At the start of World War II, Japan occupied the rubber plantations in the Dutch East Indies. This cut U.S. manufacturers off from the largest sources of natural rubber to make tires and products for the war effort. The U.S. solved the problem using rationing, recycling and lowering the speed limit to 35 mph. Another way to save rubber was to make sure brakes were in working order.

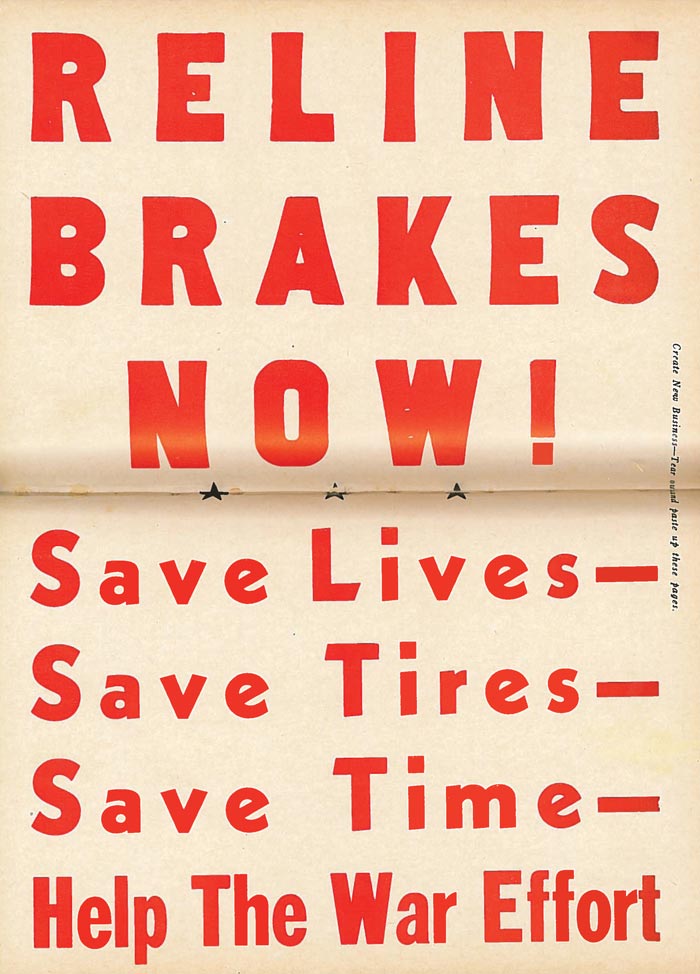

In the 1940s, most vehicles had drum brakes that did not self-adjust. If a brake shoe was worn, it might cause the wheel to lock when the brakes were applied. If the brakes were not adjusted, one wheel may lock before the others. Locking the brakes causes increased tire wear and more rubber to be taken away from the war effort.

Scientists had not figured out how to make synthetic rubber or artifical rubber in large quanties. Many communities contributed to the war effort by having rubber drives that collected anything made of rubber. BRAKE & FRONT END printed this pull-out poster in the April 1944 issue for shop owners to hang in their windows.