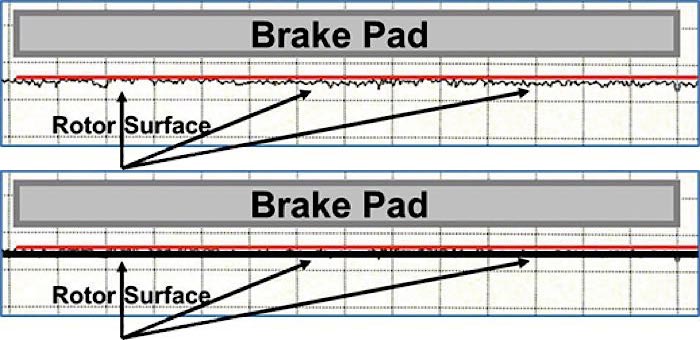

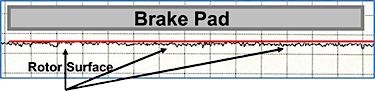

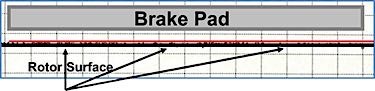

An effective burnish cycle to seat the friction materials into the opposing rotor and drum surfaces requires approximately 200 stops. The 200 stops are consistent with the burnish procedure outlined in the FMVSS 105 and FMVSS 135. As 200 stops may not be practical for many repair shops, we recommend the following burnish procedure:

• Make approximately 20 complete stops from 30 mph

– OR –

• Perform 20 slowdowns from 50 mph to 20 mph with light to moderate pedal pressure

• NO PANIC STOPS

• Allow at least 30 seconds between brake applications for the brake pads or shoes to cool down

• It is critical to follow cooldown procedures to avoid damaging NAO, ceramic and semi-metallic friction material, as well as the rotor/drum

• No high-speed stops and/or braking under heavy loads that could result in glazed or otherwise damaged linings

Using these guidelines, the friction materials will have conformed to the surfaces of the rotors and drums for improved stopping performance. In addition, the thermal conditioning of the friction materials during this process will increase the stability of braking effectiveness over a greater range of temperatures compared to when they were first installed.

It’s a good practice for repair shops to communicate with their customers that the friction materials and rotors have been conditioned and that the customers should continue this process by avoiding aggressive braking for a couple of days. Good communication will be helpful and prevent comebacks.

Courtesy of Wagner Brake