The brakes on the Chrysler Sebring/200 and Dodge Avenger are relatively problem free. There are very noise or pulsation complaints. There are no recalls or specific TSBs for the brakes.

Replacing the brake pads and rotors is straightforward. But, care has to be taken to make sure the calipers are free and the rotors are true.

The Chrysler 200 uses a TEVES MK25 ABS system antilock brakes with Electronic Stability Control (ESC) and Electronic Variable Brake Proportioning (EVBP). EVBP is used in place of a rear-proportioning valve. The EVBP system uses the ABS system to control the slip of the rear wheels in partial braking range. The braking force of the rear wheels is controlled electronically by using the inlet and outlet valves located in the ABS modulator.

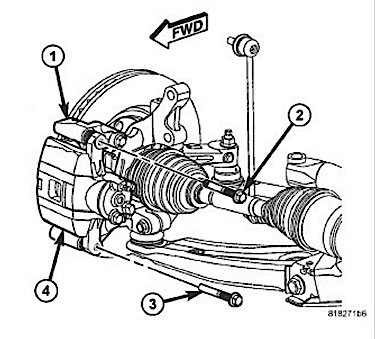

Front Brakes

The front brakes are straightforward and have very few noise complaints. The average life of the front pads is around 30,000 miles according to reports online.

The upper guide pin bolts have a special sleeve that helps to reduce vibration. The front pads only have abutment clips. The guide pins have a torque spec of 32 ft/lbs. The caliper bracket bolts have a torque specification of 80 ft/lbs.

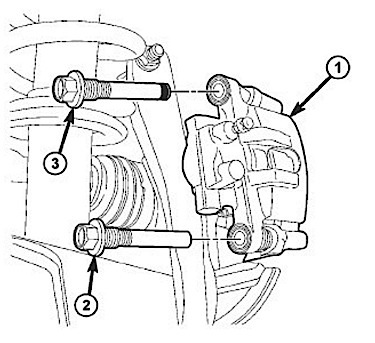

Rear Brakes

The rear brakes use a single piston caliper mounted on two guide pins that have a torque spec of 32 ft/lbs. Like the front, the upper pin has a special sleeve designed to eliminate noise.

There are two abutment clips on the inner pads supports, the outer pad is held in with a clip. Place the brake pad with the audible wear indicator attached on the inboard side. The audible wear indicator should be positioned at the bottom when installed.

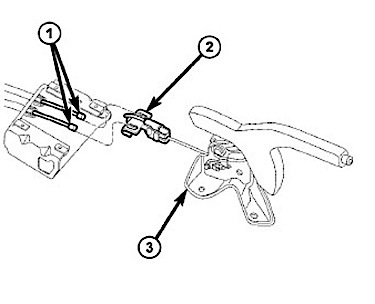

The adjuster can be accessed through a hole in the rotor. To turn the star adjuster, align the left side to seven o’clock and the right side to five o’clock. When adjusting the parking brake shoes with the drum-in hat rotor installed, rotating the adjuster wheel upward will loosen the adjustment. Rotating the adjuster wheel downward will tighten the adjustment.

With the parking brake lever in the fully applied (up) position, attempt to hand rotate each rear brake rotor to ensure that the parking brake shoes are working properly. With the parking brake lever in the released (down) position, rotate each rear brake rotor to ensure that the parking brake shoes are not dragging.

If you have to service the lever the cable that goes from the lever to the equalizer bar has a special clip that sets the tension for the cables. Chrysler calls this a “bent nail” and is designed to stretch a quarter inch when the nut on the cable is adjusted. The bent nail adjuster on the equalizer bar should be replaced if the cables are replaced. There should be 22mm of threaded bolt exposed past the top of the nut.