Bosch has been manufacturing and supplying automotive parts and systems to vehicle manufacturers since the very beginning of the automobile. As inventor, manufacturer and supplier of many ground-breaking automotive technologies – such as the oxygen sensor which was introduced in 1976 – to original equipment manufacturers (OEMs), Bosch enjoys a unique position in being able to bring OE-level quality, fit and function to its aftermarket products.

Bosch has been manufacturing and supplying automotive parts and systems to vehicle manufacturers since the very beginning of the automobile. As inventor, manufacturer and supplier of many ground-breaking automotive technologies – such as the oxygen sensor which was introduced in 1976 – to original equipment manufacturers (OEMs), Bosch enjoys a unique position in being able to bring OE-level quality, fit and function to its aftermarket products.

“Oxygen sensors are a major engine management device,” said Dave Pankonin, group product manager, “and Bosch’s leadership position, quality control programs and advanced marketing in this category have made it the world’s largest manufacturer and supplier of oxygen sensors to OEMs and the aftermarket. Bosch oxygen sensors cover 99.9 percent of vehicles in operation (VIO).”

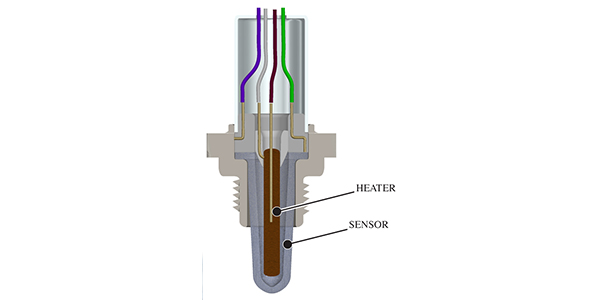

Introduced by Bosch to the aftermarket in 1980 – soon after the OEMs adopted it in 1976 as part of the tightening emissions laws in the United States – oxygen sensors function as a means to measure tailpipe pollutants. Positioned both upstream and downstream of the catalytic converter in today’s exhaust system, the oxygen sensor measures the richness or leanness of the exhaust and delivers feedback to the engine control unit (ECU) enabling it to adjust the air to fuel ratio to make the combustion as efficient as possible.

In 2005, Bosch received the prestigious Technology innovation Award for oxygen sensors from Frost & Sullivan, a global strategic and marketing consulting firm. The award was presented to Bosch “for demonstrating category excellence in technology innovation, being first to market and providing new product or process introduction in comparison with other aftermarket participants.”

According to Pankonin, “Total quality is the hallmark of all Bosch products whether OEM or aftermarket. And all subsequent improvements on a part that was OEM at the outset, are incorporated into the aftermarket part so that sometimes a replacement part can actually be better than OEM.”

Bosch advises motorists to check and or replace a “lazy”oxygen sensor with every tune-up to improve vehicle performance, reduce harmful exhaust emissions, save on fuel cost and prevent premature failure of the catalytic converter.

The Bosch portfolio of oxygen sensors includes the latest wideband, planar and heated and unheated switching sensors. It also includes the recently introduced complete OE SmartLink sensor system, which allows 14 OEM-specific, heated oxygen sensors to cover up to 96.2 percent of all OE domestic and import vehicle applications by simply installing the sensor on the existing wire harness. A 24” extra-length wire harness allows for replacement of any worn wire from the existing harness. The OE SmartLink system features a waterproof connector body; special high-temperature Posi-Lock connectors; resistance to vibration, thermal exposure and thermal shock. The OE SmartLink system installation kit contains all necessary components to do the job right.

Bosch is a proud supporter of the Automotive Aftermarket Suppliers Association’s Know Your Parts education and awareness campaign. This initiative promotes the importance of quality brand name aftermarket parts backed by full service suppliers, and its impact on delivering reliable products to today’s motorists. For more information, visit www.AASAKnowYourParts.org.

Posi-Lock Connector is a trademark of Swenco Products, Inc.

For more information on Bosch Automotive Products, visit www.boschautoparts.com.