For the BMW 7 Series E65/E66 manufactured between 2001-’08, engineers went with an innovative rear air ride system. The Dynamic Drive system that uses active anti-roll bars to keep the vehicle level was standard on these models. Some of these vehicles have optional Electronic Dampener Control (EDC) that tunes the compression and rebound of the dampener to the movement of the wheels and body for the best possible ride.

For the BMW 7 Series E65/E66 manufactured between 2001-’08, engineers went with an innovative rear air ride system. The Dynamic Drive system that uses active anti-roll bars to keep the vehicle level was standard on these models. Some of these vehicles have optional Electronic Dampener Control (EDC) that tunes the compression and rebound of the dampener to the movement of the wheels and body for the best possible ride.

This air ride system is highly integrated into the vehicle’s sensors and systems. It can even be said that the air ride system and suspension system use more sensors than the engine. The air ride system has more than 100 codes that can be set by the two modules that control the chassis system.

The most common codes you will see with these systems are CAN communication codes. If you are not able to diagnose serial data bus wiring problems, you will have problems diagnosing these vehicles.

Other common codes you might see are “plausibility” codes for the compressor, sensors and reservoir. When you see a code with “plausibility” in the description, it is the system saying that there was an unexpected result with a correction or action taken.

Modes and Filters

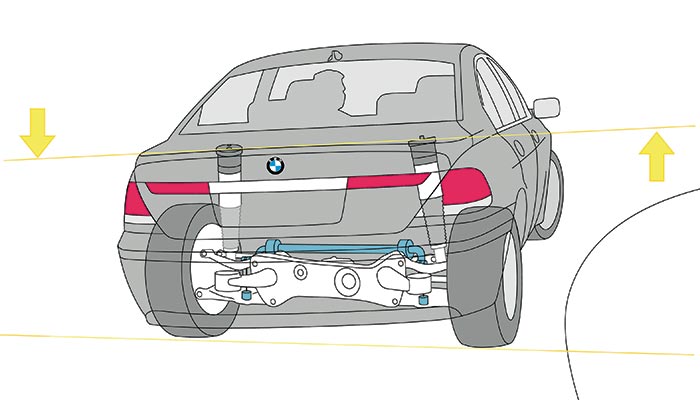

The task of the self-leveling suspension is to control ride height at the rear axle back to the target level if the load changes. The system works by feeding air in or extracting air out of the air bladders. The height sensors provide the control module with information on the heights. If the heights are outside the specified tolerances, the system intervenes using the air supply to trim the vehicle for a given mode or condition.

Most of the changes to the load take place when the vehicle is at a standstill before or after a drive. The system wakes itself up when the doors or trunk are opened and switches off 16 minutes after the vehicle has been parked.

In order to distinguish load changes from other disturbances such as road irregularities, the control modules filter the height signals. The modules will use inputs like wheel speed and lateral/vertical accelerometer data to verify the condition of the vehicle.

The system will shift between modes as conditions change. These changes also include changes in key and vehicle security.

System Modes

The air ride system on the BMW 7 Series has 10 air ride modes. Two of the 10 modes are used by the factory and dealership for transport and manufacturing. The eight other modes are used by the system to trim under various conditions.

Sleep: The sleep mode is the initial state for interventions. No changes in ride height take place.

Pre: In the pre mode, the load-cutout message of the power module initiates a time-controlled pre-run and after-run trim of the vehicle. The load-cutout signal is set by activities on the vehicle such as pressing the door handle or operating the central locking system and output on the K-CAN data bus. If the vehicle is parked, the load-cutout signal remains set for approximately 16 minutes after the last action.

Post: The post mode is used to balance out any visual inclination before entering the sleep mode. Intervention takes place within a narrow tolerance range of 7 mm.

Normal: The normal mode is the starting point for the normal operating status with the engine running. The fast filter is used with a narrow tolerance range of around 10 mm. It is a narrower tolerance range than pre mode and can be used because the alternator is working.

Drive: This mode is activated when the wheel speed sensor starts to detect movement. This mode is used when the car is moving and can be used to level the vehicle as fuel is consumed.

Curve: This mode is used to trim the vehicle in corners to keep the vehicle stable. It uses inputs from the height, steering angle and yaw/accelerometer cluster. Curve mode will add pressure to the outside wheels to level the vehicle. This mode quickly switches in and out of drive mode.

Kerb: This mode detects if the vehicle is parked with one or two wheels on an obstacle such as a curb, or if there is a wheel in a gutter. This prevents the vehicle from driving off with the suspension at uneven ride heights if the vehicle tries to self-level. This mode activates both the left and right sides if the difference is greater than 24 mm.

Lift: The lift mode will activate if the vehicle is lifted or jacked up in the shop. This mode is looking for suspension rebound that’s greater than 55 mm. The vehicle will rise slightly and stop other modes that may make the vehicle unstable if the customer is changing the tire. The mode typically deactivates when the system detects forward vehicle movement.

Dynamic Drive System

All E65 and E66 models have the Dynamic Drive system working with the air ride system to level the vehicle. The system uses two active anti-roll bars that are hydraulically controlled. It is an infinitely variable anti-roll bar that can push back. This allows for better wheel travel on bumpy roads and better body control in the corners without the disadvantages of a too-thick or too-thin anti-roll bar.

The Dynamic Drive control module uses the input signals from the height sensor, accelerometers mounted near the suspension towers, and a range of other sensors to control the hydraulic motors on the bars. The hydraulic system also has sensors to manage the pressure and valves.

From a diagnostic perspective, there is not much that can go wrong on the mechanical side. However, the electronic side is another matter. This system uses a lot of bandwidth on the CAN bus. Later models moved the Dynamic Drive and Electronic Dampener Control systems to a Flex Ray serial data bus. If you see a large number of communication codes in other models, this could impact the operation of the ride control system due to loss of information that the system needs to operate.

On higher-mileage E65/E66 models, the compressor will wear out before the air shocks. If you are pulling codes for compressor or reservoir plausibility errors, or codes that say the compressor timed out, it could be time for a new compressor. If an air shock has been damaged and the vehicle has high miles, it is a best practice to replace both units and the compressor.