Where does brake noise originate from?

Where does brake noise originate from?

When a brake pad makes contact with the rotor, it causes the brake pad and rotor to vibrate. This is “ground zero” for all brake noise. If the vibration is transmitted through the brake pad’s backing plate and into the caliper and bracket, this could generate noise the driver could hear if the frequency is between 20- and 20,000-Hz.

How do shims absorb these vibrations and prevent noise?

Brake shims prevent and reduce the transmission of vibrational frequencies that cause excitation of the caliper, pad assembly and attached structure. The OEMs engineer shims to solve specific vehicle noise problems and eliminate certain frequencies. Using a generic or less expensive alternative technology for a brake shim may result in noise problems for the driver.

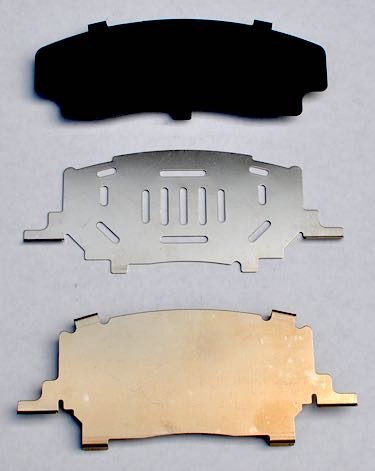

For certain Toyota (import and domestic manufacturer) applications, Asimco uses a two-piece shim like the original design. The outer shim is made from a sandwich of visco-elastic damping material and anodized stainless steel. The inner shim is made from anodized stainless steel that is not prone to corrosion. The inner and outer shims firmly clip onto the backing plates. The outer shim can move against the inner freely, this prevents vibration from being transferred to the caliper and suspension.

These corrosion-resistant layers can prevent noise over the entire lifetime of the brake pads, unlike some lubricants that can dry up and wash away.

These corrosion-resistant layers can prevent noise over the entire lifetime of the brake pads, unlike some lubricants that can dry up and wash away.

Most aftermarket brake pad manufacturers will use a single shim attached to the pad by using pressure-sensitive adhesives or other methods of mechanical attachment, and they do not float where they are required to. Also, the shims could be made of materials that do not dampen vibrations and are prone to corrosion. This could lead to noise problems long before the friction material is worn below replacement specifications.

About Asimco

Asimco’s roots stem from nearly 20 years of OE-supply manufacturing. The processes and quality control standards are OE-specific, resulting in a product that delivers the proper fitment and functionality. We pride ourselves on the formulation that is made with premium ceramics and is low-copper-standard compliant.

Courtesy of Asimco Brakes