While Saab as a company may no longer be around, its cars are still on the road and need alignments. The Saab 9-3 is built on the GM Epsilon platform that is shared with Chevrolet Malibu; however, Saab reengineered almost everything. It was revealed in the bankruptcy of the company that only 20% of the parts came from GM. The Saab 9-3 uses almost the same front end and multi-link rear suspension as the Malibu, but Saab has improved the bushings and geometry.

Front Suspension

The front suspension on the 9-3 uses a MacPherson strut mounted to a cast-iron knuckle and aluminum control arm. The ball joint is part of the control arm and cannot be replaced on its own. At the first signs of play, the ball joint should be replaced. The ball joint rests in a low-friction plastic insert. When the insert wears away due to contamination, the friction between the hardened metal stud and aluminum of the control arm can cause a fast failure.

The front caster is not adjustable and the angle can be used to determine if there is suspension or body damage. Too much cross caster can cause the vehicle to pull in the direction of the side with the most negative caster. Also, if the caster is out of specifications, check the condition of the control arm bushings.

Camber can be adjusted by installing cam bolts in the lower strut mounting holes. Cam bolts can give an ±1.75º of camber.

If the vehicle is pulling in one direction, look at the cross-camber angle. The cross-camber is the difference between the left side camber and the right side camber (cross-camber = left camber – right camber). Positive cross-camber may cause the vehicle to pull to the left. For example, if the vehicle pulls to the left, adjust the cross-camber more negative, and vice-versa. If the camber specification of either wheel is outside of specification after using this technique, look for other culprits like a pulling tire or damaged control arm affecting the caster angle.

Another problem area is the upper strut mount. As the upper mount degrades or collapses, the camber will change and cause a tire wear problem. It is also possible for the upper thrust bearing to become damaged. When it fails, it will make a knocking noise that sounds like a worn sway bar link. Also, the failed bearing can cause the steering to bind. The upper strut mount is one of the items that Saab reengineered.

Broken springs are also a common failure on high-mileage 9-3 models. Usually, the lower coil will break. This will cause ride height and camber issues. Replacements are available, but make sure you have the correct VIN and options information before ordering.

The most common complaint from 9-3 drivers is outside edge front tire wear. The only cure is to make sure the total toe is as close as possible to the specification.

Rear Suspension

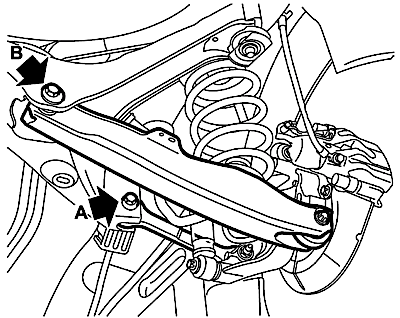

The four-link rear suspension is robust and has built-in adjustments for camber and toe. To adjust the camber, loosen inner lower control arm cam-bolt nuts and adjust the cam bolt to the correct specification. To adjust the rear toe, loosen the inner toe link cam bolt and nuts. Rotate the cam bolt to the required toe specification settings. The rear cams have a significant cross talk, so always recheck both angles after any adjustment of eith er cam.

er cam.

Steering

This generation of the 9-3 has electronically controlled hydraulic power steering. On four-cylinder models, the pump is powered by the camshaft. One of the most common failures on this vehicle is that the seal on the power steering pump fails and pressurized engine oil enters the system. It may appear that the reservoir was simply over-filled by a well-meaning customer or lube tech, but the real cause is power steering pump shaft seal failure. After the pump is replaced, flush the system with fresh power steering fluid.

The power steering system uses a combination of steering shaft torque sensor input, vehicle speed and steering angle to determine the amount of steering assist. The system has a steering angle sensor that must be recalibrated after the toe or thrust angle has been adjusted.

After an alignment is performed, it is required that the steering angle sensor and torque sensor are calibrated in order for the system to function properly. This is performed through the OBD-II diagnostic connector.

Only perform the steering position sensor recalibration procedure after the tires, suspension and alignment specifications have been inspected and corrected. The recalibration procedure should take place on the alignment rack with the wheels straight ahead.