The rear brake calipers clunk when you first apply the brakes after changing the direction of the vehicle.

Applicable Vehicles:

• 2001-’03 MDX, all; and

• 2004 MDX, from VIN 2HNYD1…4H500001 through 2HNYD1…4H514801.

Probable Cause:

The outer shims on the rear brake pads do not allow the pads to slide easily when you press the brake pedal. This causes the outer pad to hit hard during a change of direction, resulting in a clunk.

Corrective Action:

Replace the rear brake pad shims.

Note: Brake pad replacement and disc resurfacing is not needed to get rid of the clunk.

Parts Information:

Rear Brake Pad Shim Set: P/N 06435-53V-A01

Required Materials:

M-77 Assembly Paste: P/N 08798-9010

Repair Procedure:

-

Remove and discard the rear brake pad shims (three per caliper). Refer to the 2001-’02 MDX Service Manual, page 19-16, or the 2003-’04 MDX Service Manual, page 19-18.

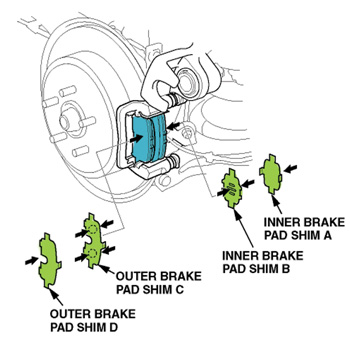

Remove and discard the rear brake pad shims (three per caliper). Refer to the 2001-’02 MDX Service Manual, page 19-16, or the 2003-’04 MDX Service Manual, page 19-18. - Apply a thin coat of M-77 assembly paste to the new brake pad shims in these areas:

- The back of inner shim A and outer shim D; and

- Both sides of inner shim B and outer shim C. See Fig. 1.

- Install the new brake pad shims (four per side) on each rear caliper. Refer to the 2001-’02 MDX Service Manual, page 19-17, or the 2003-’04 MDX Service Manual, page 19-19.

Technical service bulletin courtesy of ALLDATA.

For additional information, visit www.alldata.com.