r set for overdrive and a roller clutch to drive the output shaft. The Borg Warner and Doug Nash mechanicals are quite different from the GV overdrive. This is most probably the reason they are no longer in production. The Borg Warner used a shifting a linkage, collar and gear to mechanically connect the input and output shaft for reverse.

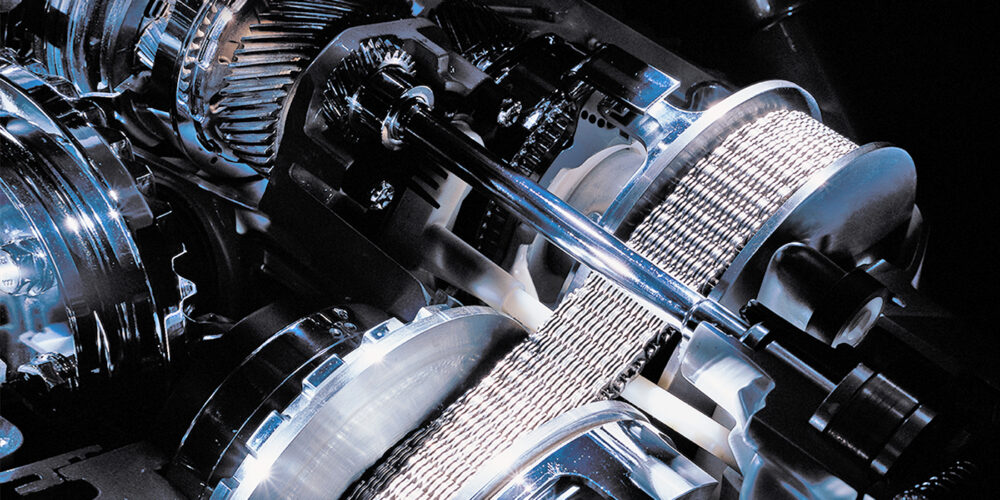

When the collar and gear is disengaged from the output shaft, the input shaft is connected to the planetary gear set and roller clutch producing direct drive. A solenoid-operated pawl would engage a dog clutch to stop the sun gear and turn the planetary gear set for overdrive (Figure 1). All overdrives use a roller clutch to engage the planetary gear set and ring gear to the output shaft. The Borg Warner roller clutch will not allow compression braking, or reverse. This is freewheeling and it was both a good and bad feature. It also had a governor that would not allow the solenoid to operate the pawl and dog clutch to engage the overdrive below a certain vehicle speed.

The MH5 overdrive used an automatic transmission type clutch pack to engage the planetary gear set to the ring gear and a band type clutch to control the rotation of the sun gear. The GV overdrive uses a conical clutch to engage and disengage the planetary gear set. The roller clutch is designed to engage the ring gear in forward gears and provide compression braking under deceleration and reverse (Figure 2).

The MH5 overdrive used an automatic transmission type clutch pack to engage the planetary gear set to the ring gear and a band type clutch to control the rotation of the sun gear. The GV overdrive uses a conical clutch to engage and disengage the planetary gear set. The roller clutch is designed to engage the ring gear in forward gears and provide compression braking under deceleration and reverse (Figure 2).

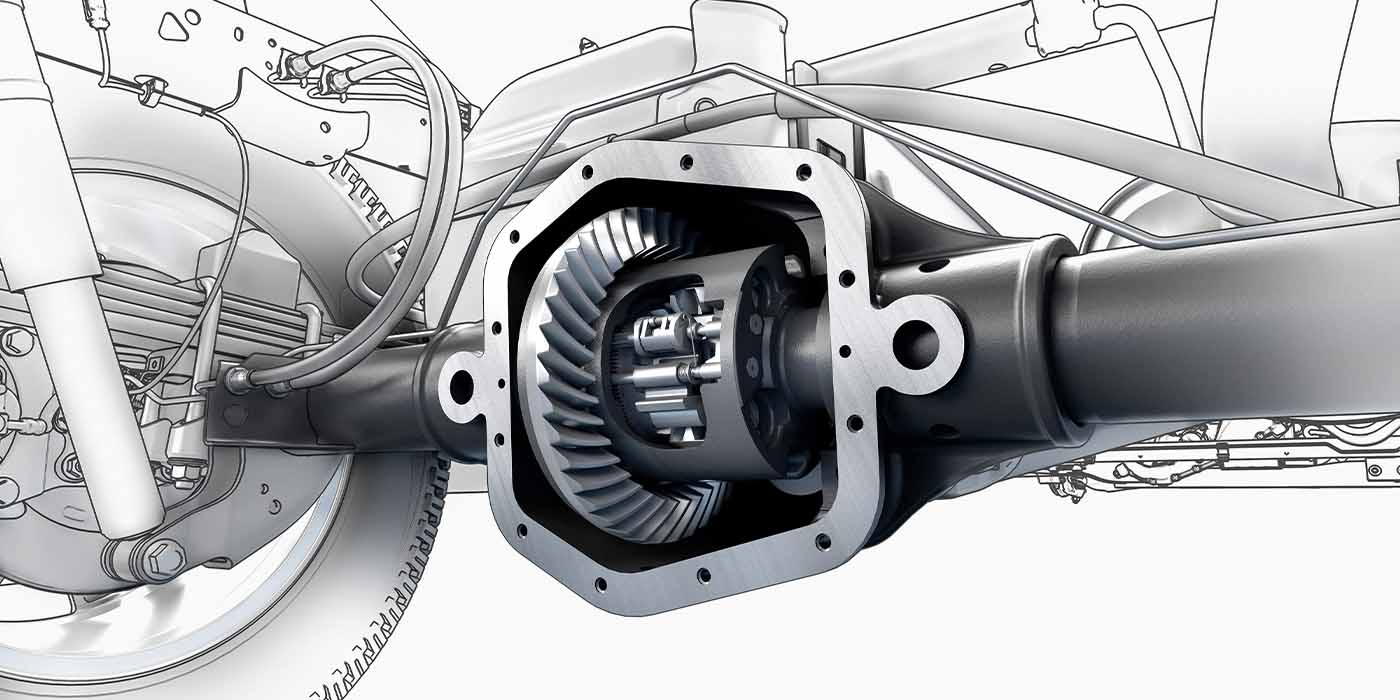

The GV overdrive’s main components are made up of an actuator, planetary gear set, actuator clutch and roller clutch. The planetary gear set is made up of a sun gear, planetary gear carrier, and a ring gear. The sun gear is attached to the actuator clutch assembly. The planetary gear carrier is attached to the input shaft. The ring gear drives the roller clutch. The roller clutch is splined to the output shaft.

The actuator clutch has a cone shape surface and friction material on both sides to engage and disengage the actuator clutch. The actuator uses springs for direct drive and hydraulic pistons to engage overdrive. The hydraulic pistons that operate the actuator clutch are powered by a piston-type pump driven on an input shaft eccentric (Figure 3). Pressure from the pump is sent to the pistons by a solenoid valve and pressure regulator.

When the sun gear is held stationery and the planetary gears and carrier are rotated by the input shaft, the ring gear drives the roller clutch faster than the input shaft (Figure 4). The sun gear (S) has 23 teeth, each planetary gear has 16 teeth (P) and the ring gear has 52 teeth (R). For every 45º of rotation of the planetary gears and carrier, the ring gear will rotate 66º. The ratio for the gear set in overdrive can be calculated using the formula: [1 ÷ (1+ S ÷ R) with values 1÷ (1+ 23 ÷ 52)]. For the gear set, the ratio is 0.693 to 1 or rounded to the nearest tenth 0.7 to 1.

The overdrive is to the internal combustion engine and transmission what the afterburner is to a jet engine. They both produce an increase in performance with a major difference. The overdrive saves fuel and the afterburner uses fuel.

On a long pull with a load, an overdrive can provide the ability to stay at the top of the torque band. As an example, a one-ton series truck with a loaded trailer on a grade could work more efficiently in second/overdrive to maintain speed and stay at the top of the torque curve verses lugging in third or shifting to second that increases engine speed and fuel consumption.

On a long pull with a load, an overdrive can provide the ability to stay at the top of the torque band. As an example, a one-ton series truck with a loaded trailer on a grade could work more efficiently in second/overdrive to maintain speed and stay at the top of the torque curve verses lugging in third or shifting to second that increases engine speed and fuel consumption.

For the performance minded, when the cone clutch of the overdrive engages there is no slippage. It’s like a “bang” shift. That can shave tenths of a second off an elapsed time. The overdrive can turn a four-speed automatic or manual into an 8-speed. By split shifting from 1st through 4th, the transmission and overdrive have each shifted four times and produced eight speeds.

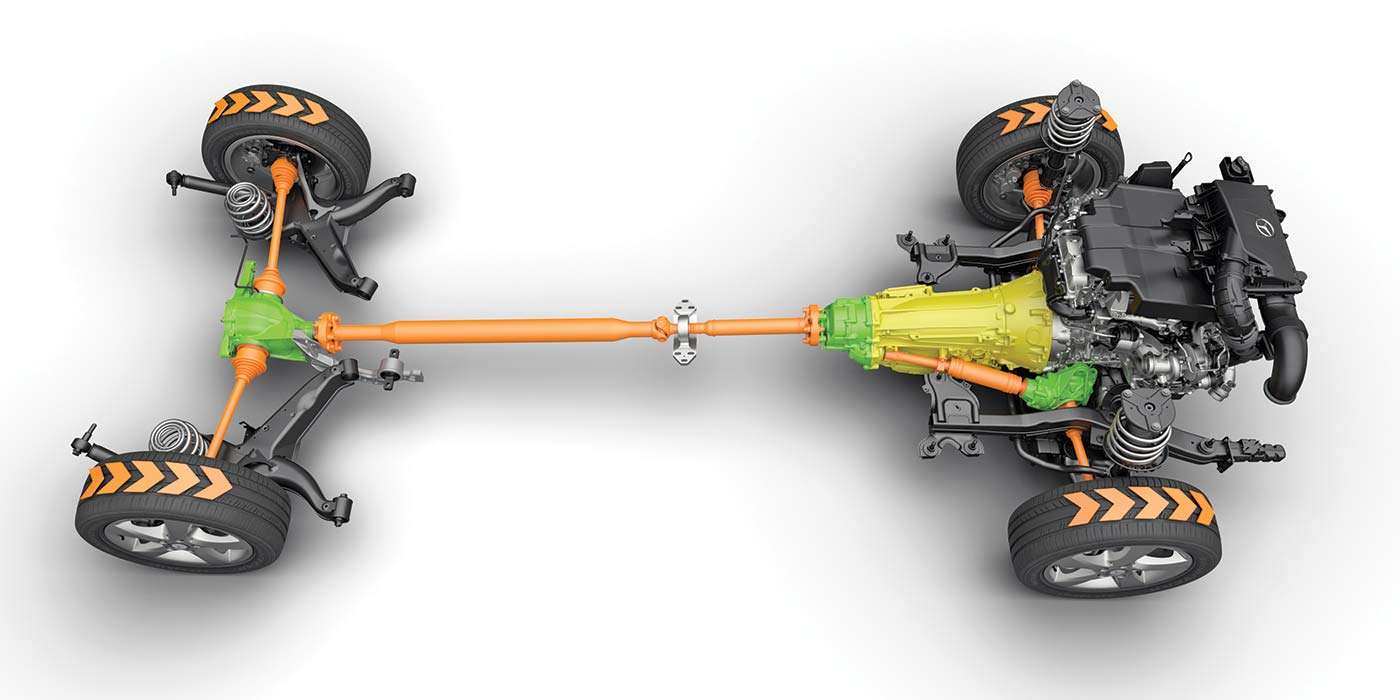

Installing an overdrive requires the removal of the transmission tail shaft housing and replacing it with an adaptor for the overdrive. The overdrive is then mounted to the adaptor.

The extra length of the overdrive will require that the drive shaft be shortened. In the case of a two-piece drive shaft, the center carrier bearing may need to be moved toward the rear and both drive shafts shortened. Installation of the control module, switches, indicator lamp and wiring completes the project.

There is a considerable cost to install an overdrive, but with today’s cost of fuel, the operator of a high mileage three-quarter or one-ton diesel can increase in fuel economy by 22% and justify the cost. If you have a need for speed and performance that can apply gobs of torque at any cost and shove you back in the seat with a trick shift, a GV overdrive could be in your future. Figure 5 is a cutaway of the real thing.