There is more computing power in the average new vehicle than was on board the Apollo spacecraft that put men on the moon. That power comes from control modules, sensors, and other components that are linked together—and those links require connectors that can withstand the vibration, moisture, and other hazards without failure. GM’s Weather Pak connectors are probably the most familiar, but there other types of connectors available. One of those is the Deutsch connector. You will find the connectors on motorcycles, heavy trucks, and construction and agricultural equipment. They are also popular for racing and off-roading due to their vibration and weather resistance.

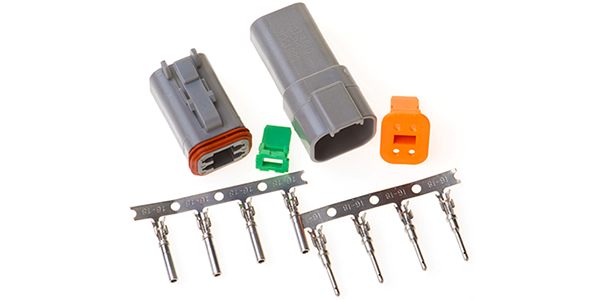

Deutsch connectors consist of male (pin) and female (socket) terminals—contacts in Deutsch-speak—and a housing with a male half (receptacle) and female half (plug). The connector you’ll most often encounter is the DT Series. There are two types of DT contacts—stamped/formed (open barrel) and solid (closed barrel). The contacts are interchangeable within the connector.

There are five common connector termination sizes: 4, 8, 12, 16, and 20. These sizes are the same regardless of the wire gauge. The only deviation in connectors is the wire gauge. DTM connectors are for 16-18 gauge wire, while DTP connectors are for 14-16 gauge wire.

DT connectors are a good option for custom wiring harnesses. They can be assembled and disassembled 100 times without electrical signal degradation, and properly wired and mated connections can be immersed in up to three feet of water without damage. You can also fit more contacts in a single connector than you can in, say, a GM Weather Pak. That reduces the number of connectors needed in a harness—and fewer connectors mean more reliability.

Deutsch DT connectors are available from multiple sources. For example, Summit Racing Equipment offers its own Deutsch Connector Kits with a selection of stamped/formed contacts and housings; you can get one with or without a crimping tool. Summit Racing also carries terminal and housing packs.

Deutsch Connector Tools

Stamped/formed terminals require open-jaw pliers to make the crimp. The writer has used an MSD ratcheting wire crimping tool with a set of MSD Deutsch connector jaw dies. With the terminal or pin installed (open end of the terminal faces up), insert a section of stripped wire into the pin, close the tool’s handles, and the wire/terminal combination is crimped.

Another option is S&G Tool’s pliers designed to crimp both Deutsch and Weather Pak terminals. It doesn’t have an internal ratchet mechanism but is less expensive at just under $28 from Summit Racing.

Deutsch connectors with solid contacts require a tool like the ones made by Techflex and S&G Tool. Simply insert the solid contact into the tool, slide in a stripped piece of appropriately sized wire, and close the handles to crimp.

Assembling Deutsch Connectors

The key to assembling Deutsch connectors is to remember that male contacts fit into the receptacle half of a connector and female contacts fit into the plug half. To install male contacts, push the wire through the orange silicone seal and into the back of the housing until you hear (or feel) a snap or a click. If you tug the wire, it should be snug. Use needle nose pliers to insert the green wedge lock beneath the contacts, flat portion facing down. Use a small flat screwdriver to push the wedge lock into place; it forces the contacts upward into a set of grooves in the top of the housing.

Female contacts fit in the connector the same way as male contacts. The difference is the wedge lock—you slide the orange-colored lock into the groove and snap it into place with your hands.

Disassembling Deutsch Connectors

Disassembling the male half of a Deutsch DT connector is easy when you have the right tool. Lisle and S&G Tools make tools with extractors sized for different gauge wires. Select the extractor for the wire you have and insert it from the back (wire side) of the socket. Push the extractor forward and you’ll feel the wedge lock release. The wire can then be removed.

Female connectors are disassembled by inserting a small flat blade screwdriver into the side of the assembly and twisting it to pop the wedge lock out. Inside the housing are two tabs. Depress them with the screwdriver and tug the back of the wire/contact assembly to release it.

Deutsch connectors are not difficult to use; provide secure, weathertight electrical connections; and don’t require expensive tools to assemble. Consider them another tool in your electrical system toolbox.