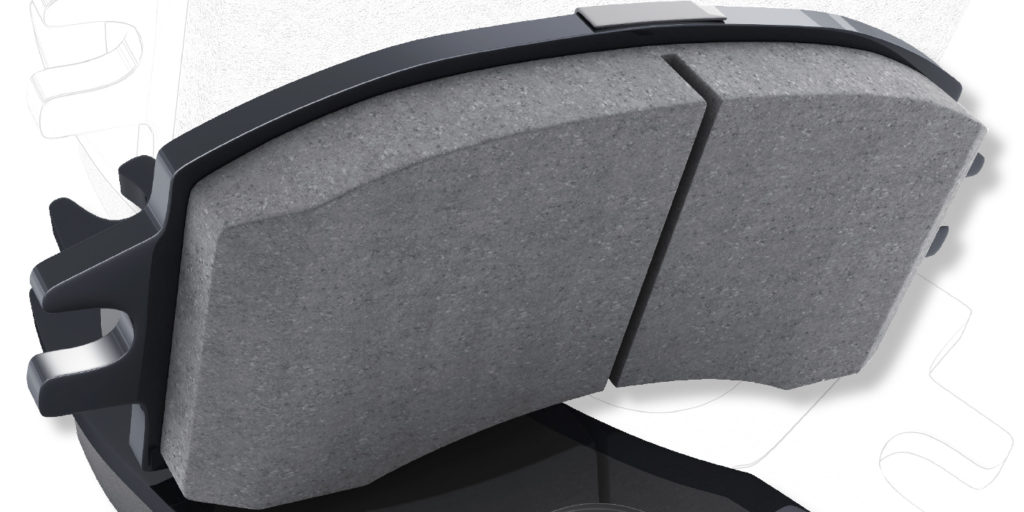

Even with zero moving parts, the common replacement brake pad is one of the most difficult components on a vehicle to engineer and manufacture. From the initial design to the final packaging, here’s a look at what it takes to make a brake pad.

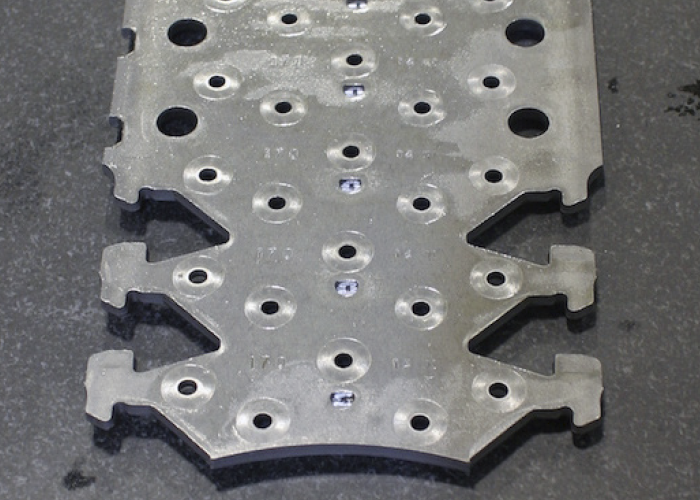

1. One of the first stages of manufacturing is the stamping of the backing plate. When the plate is stamped, it may have to go through several processes to make sure the dimensions are correct. Special features like pins, friction material retention devices and other hardware are machined after the plate is stamped. Also, surfaces that make contact with the caliper bracket are set to their final dimensions to ensure the installed pad fits properly.

2. This is the station where the components of the friction material are measured out and mixed. The operator will measure precise amounts of the components onto a scale. The precisely measured components are then placed in a special mixer. The mixer makes sure the mix is homogenous.

3. The mixture is then molded into “pre-molds.” These “pucks” will be pressed and molded onto the backing plates. This image shows a stack of the pre-molded friction pucks ready for final molding. This formulation is a semi-metallic.

4. The backing plates are placed in a mold with the friction material on top. The friction material here is an organic formulation. In press, the friction material is molded to the backing plate with pressure and heat. Some of the friction material is forced through the holes in the backing plate to increase retention. This is called “integral molding,” or IM for short. IM is only one method for attaching the friction material.

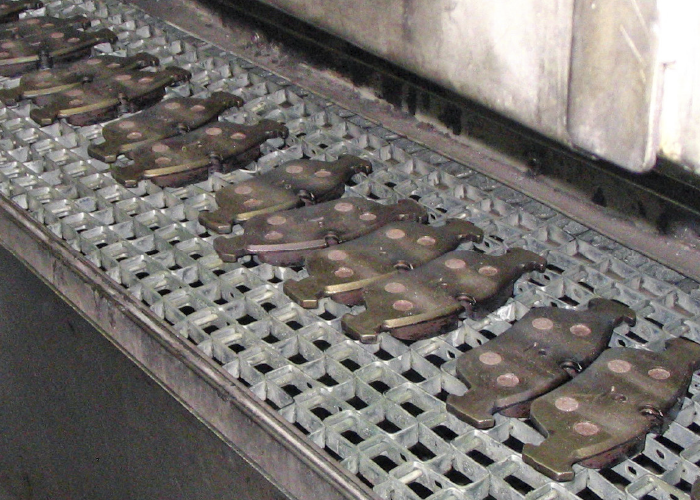

5. The brake pads will be placed in an oven to cure. The heat will activate and solidify resins, binders and other ingredients. This means consistent performance over the lifetime of the pad.

6. Now the manufacturer will cut chamfers and slots into the pads. Also, the pad will be ground to the correct height.

7. At this point, the naked pad is prone to corrosion. Some pads will have a coating applied to prevent corrosion. The coating can be a high-temperature paint or a powder coating that is baked on. Some pads will use galvanized plating on the backing plate that does not require paint.

8. Here, an engineer is testing the pad’s shear strength and compressibility. Before a batch of pads is shipped, the manufacturer will test random samples for quality control.

With the brake pads tested and shipped, the finished product is ready to make its way into your shop and onto the vehicles you repair.