VIDEO: Hub Flange Runout Measurement

Find out why it’s essential you measure the hub flange before a brake job. This video is sponsored by GSP North America.

VIDEO: Lateral Runout Threshold For Bearing Replacement

Andrew Markel discusses wheel bearing replacement, how to measure for runout, and how much runout determines when a bearing needs replaced. Sponsored by BCA Bearings.

VIDEO: Measuring Flange Runout: Two Lug Nuts, Or Five?

Andrew Markel explains best practices for new brake rotor installation by checking flange runout with a certain amount of lug nuts attached and torqued. Sponsored by BCA Bearings.

Runout And DTV: Decreasing Comebacks With Two Simple Tools

Even if you use new rotors, your chance of a pulsation comeback could be greater than if you left the old rotors on the vehicle. Runout in the hub and new rotor can stack up to cause disc thickness variation (DTV) in a few thousand miles. DTV is the main cause of pulsation.

VIDEO: Wheel Bearing Runout

Andrew Markel shows how cleanliness is next to godliness when installing a new rotor on an existing hub and flange on a vehicle. Sponsored by Auto Value and Bumper to Bumper Parts Stores.

Brake Runout TSBs on Pulsation: What do They Mean?

If you are combing through brake technical service bulletins (TSBs) on a repair information database, chances are you will come across a TSB discussing brake pedal pulsation (not warping). Most of the time, the TSB will outline new warranty procedures so the manufacturer can reimburse the dealership. Some recommend improved pads and rotors. Other TSBs

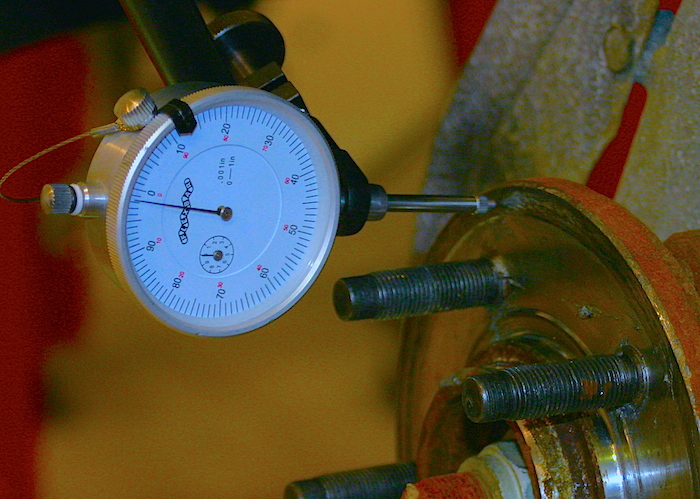

Torque And Runout: Measure Twice, Install Once

There are two critical measurements when installing a modern hub unit or cartridge bearing: torque and runout in the flange. Ignoring these critical numbers to save time will only lead to more comebacks and angry customers.

Finding, Fixing Runout and Disc Thickness Variation

Now that the warped rotor myth is busted, and we’re not just replacing the rotor and moving on, what are we doing instead? Measuring runout First, check for rotor surface runout with the wheel mounted. Components should be marked as you perform an inspection of the assembly. By measuring the rotor on the hub, you

ASE A5 Test Prep: Brake Pulsation And Runout

Being able to diagnose and solve brake rotor pulsation problems is critical to passing the ASE A5 exam for brakes. Pulsation and brake performance problems may not seem to be the most difficult, but they often cause the most headaches for technicians. Below are sample questions based on the A5 task list, written by the editors

Measure Rotor Thickness, Runout: Stop Pulsation Comebacks Before They Start

Let’s say a vehicle had .003″ of lateral runout when measured at the outside face of the rotor. If this vehicle is riding on 205/55R16 tires, in one mile, the high-spot with .003″ of runout goes past the caliper approximately 836 times. Over 6,000 miles, that spot on the rotor will go past the pads more than 5 million times. Every time this spot passes the pads, a little bit of the rotor’s material is removed. Over the course of those 5 million revolutions, enough material is removed to create a thickness variation that can be felt by the driver. This is why it is critical to measure thickness and runout in a brake rotor and wheel flange even if new rotors are going to be installed.