This popular Jeep has been on the roads for almost 70 years, starting off as the CJ (Civilian Jeep) and changing names to the Wrangler in the late 1980s. The great thing about performing a brake job on a front solid axle Jeep is noise complaints hardly ever happen. The mass of the axle absorbs noise and vibration.

The main problems you will encounter are pulsation and judder from the front brakes. The cause of the problem is excessive lateral runout when new rotors are installed. The cause is usually runout in the flange caused by an impact or corrosion amplified by the new rotors. The runout specification is less than .002”.

The Jeep has electronic brake distribution controlling the brake bias. The rear brake pads will wear at the same rate as the front for some drivers. The system helps to prevent nose dive during stops for traffic lights and stop signs.

Parking Brake Adjustment

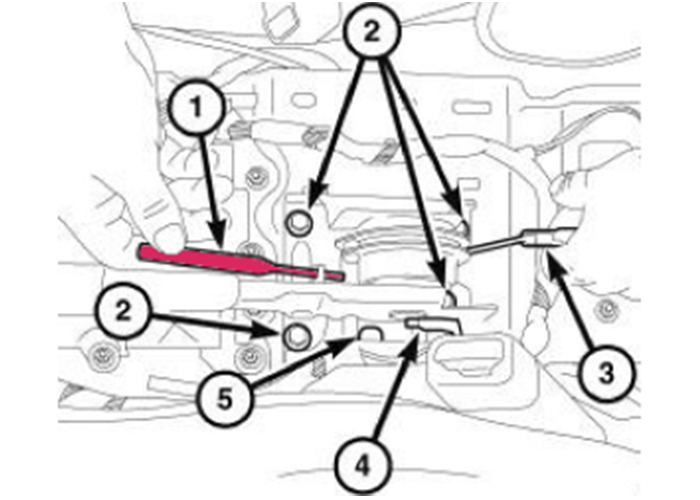

The rear brakes use a drum-in-hat parking brake. Adjustments can be made to the equalizer bar to change the amount of movement of the lever. Removal of the center console is required. The brake lever is locked out with a screwdriver or drift.

Adjustments to the parking brake drums at the wheels can be made with the rotor on or off.

1. Be sure the parking brake lever is fully released.

2. Raise vehicle so rear wheels can be rotated freely.

3. Remove plug from each access hole in brake support plates.

4. Loosen parking brake cable adjustment nut until there is slack in front cable.

5. Insert adjusting tool through support plate access hole and engage tool in teeth of adjusting screw’s star wheel.

6. Rotate adjuster screw star wheel (move tool handle upward) until slight drag can be felt when the wheel is rotated.

7. Push and hold adjuster lever away from the star wheel with a thin screwdriver.

8. Back off adjuster screw star wheel until brake drag is eliminated.

9. Repeat adjustment at the opposite wheel. Be sure adjustment is equal at both wheels.

10. Install support plate access hole plugs.

11. Adjust parking brake cable and lower vehicle.

12. Depress park brake lever and make sure park brakes hold the vehicle stationary.

13. Release park brake lever.

Bleeding

The brakes can be bled with a power bleeder. Jeep recommends a pressure between 15-20 psi. Manual or two-person bleeding is possible, just take care not to bottom out the dedal and master cylinder. Damage to the seals can occur on higher-mileage Wranglers.