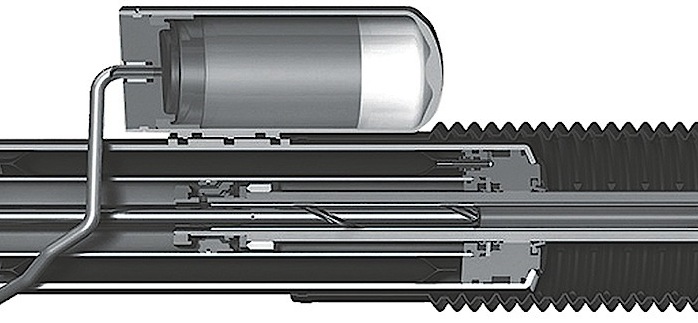

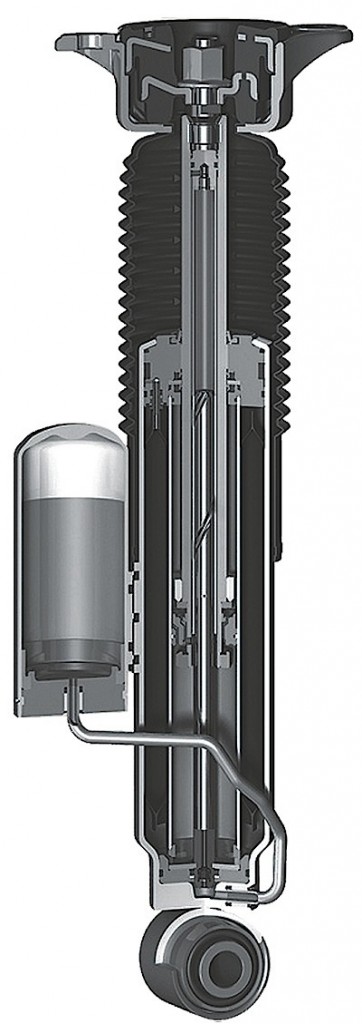

Nivomat shocks can be found on a variety of vehicles. They are self-leveling shocks that use an internal pump on the piston to control the level of the vehicle. There are no external lines or connections.

Nivomat shocks can be found on a variety of vehicles. They are self-leveling shocks that use an internal pump on the piston to control the level of the vehicle. There are no external lines or connections.

Five Signs a Nivomat is Bad

Sagging: If you load the trunk of a vehicle with Nivomats, the rear end will go down. After driving the rear end should return to the correct ride height. If the suspension does not return to the correct ride height, the Nivomat units likely need to be replaced. If the load is removed, the ride height should stay the same.

Side-to-Side Lean: If one Nivomat unit has failed, the rear ride height will be lower on that side. If you detect a difference in ride height from side-to-side greater than an 1.5”, inspect the Nivomats for leaks and operation.

Ride Quality: A Nivomat is still a conventional shock absorber at its core. Wear to the valves, seals and internal surfaces will happen just like a normal shock or strut. If a vehicle does not hold the road or feels like it is floating, have a look at the Nivomats.

Noise: A dead Nivomat can make a lot of noise if the load-leveling components are flat or not pumped up or functioning.

Leaks: Nivomats will leak at the shaft seal and at the top of the body.

Diagnostic Strategy

Testing the function of a Nivomat shock, requires measuring the rear ride height and driving with a load.

- Measure the ride height. This can be done with a simple ruler. Drive the car onto a level surface. You can either measure the distance from the center of the wheel to the top of the wheel well or check the service information for the OE measuring points.

- Load the rear of the vehicle with at least 200 lbs, as close to the axle as possible.

- Measure the ride height. Write down the measurement.

- Drive the vehicle for at least three miles.

- On the same flat surface, measure ride height.

The ride height should return to the same measurement from when it was unloaded. If it is at the same ride height that was measured when the vehicle was loaded, chances are the Nivomats have failed internally.

Applications

• Cadillac STS (2005-’09)

• Cadillac CTS FE4 (2004-’07)

• Cadillac SRX 2004-’09 (Comfort Suspension)

• Chevrolet Suburban, Tahoe (check RPO code) (2000-’06)

• Chrysler/Dodge Minivan (option) (1996-’06)

• Chrysler Pacifica FWD (2004-’08)

• Chrysler 300/Dodge Charger/ Magnum (option)(2004-’10)