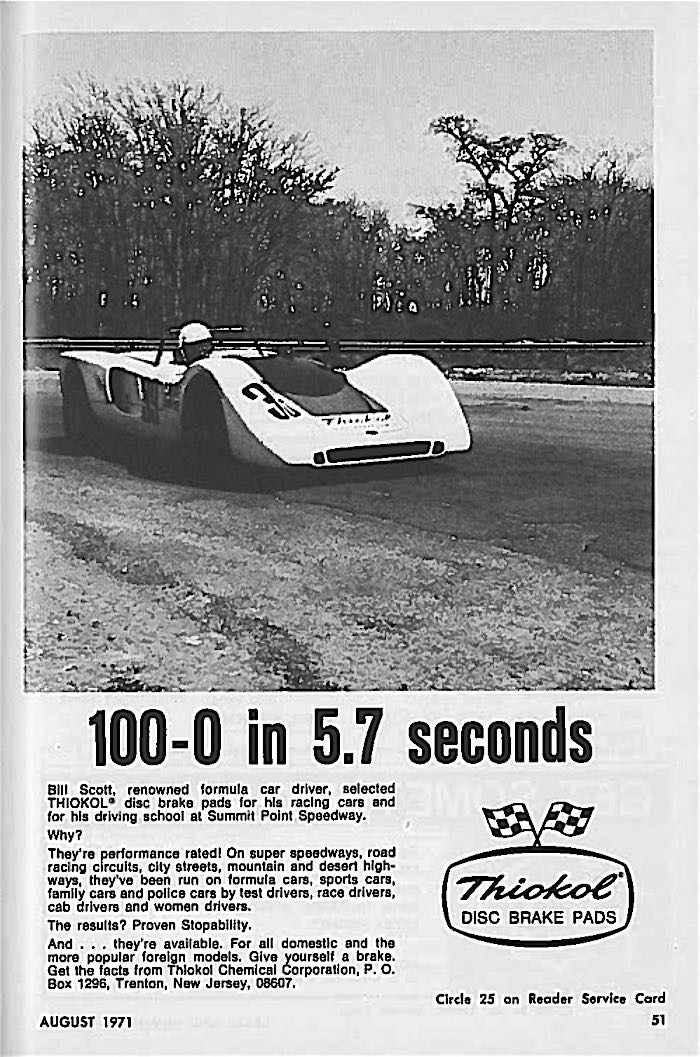

What is the connection between nuclear missiles and brake pads? The answer is Thiokol. The company was founded in 1929, and the name roughly translates to “sulfur and glue” (two components used in brake pads) in Greek. Thiokol was a government contractor for solid rocket engines that were used in everything from ejection seats to the rocket boosters for the Space Shuttle, but they were also a popular manufacturer of brake pads.

While Thiokol’s involvement with both rockets and brakes might not seem obvious, solid rocket boosters and brake pads have a lot in common in their manufacturing processes. Both products involve mixing solid substances, adding a resin and compressing them into a mold. The only difference is one makes friction while the other produces a controlled explosion.

In the late 1960s, the company decided to focus on their solid rocket engines and sold off their non-defense businesses, including their brake business in 1968, which continued on as Friction Division Products.