Some parts of the country are plagued by car-destroying corrosion. Whether the acceleration is caused by proximity to the ocean or by chemicals used for road treatment, corrosion can really take a toll on vehicles and the people who are dependent on them.

For those working on cars in parts of the country where this type of corrosion is most prevalent, you don’t need me to tell you how bad it can be. On the other hand, if you’re working on cars in somewhere like Arizona, you probably don’t have to worry about corrosion that much — except for TPMS sensors.

For TPMS sensors, a harsh environment isn’t a requirement to see valve seizing corrosion take hold. The most common type of corrosion we typically see affecting TPMS sensors is of the galvanic variety. Galvanic corrosion doesn’t depend on your location. Sure, the same environmental factors that accelerate typical corrosion will still affect the TPMS hardware no matter what, and if you’re in Arizona, that TPMS hardware will still have an advantage over somewhere like Maine. But you can’t run from galvanic corrosion, regardless of your location.

Relationship Basics

Have you ever been around someone that you just can’t find anything in common with, someone who wears you down, someone who’s all take and no give? Well, that’s sort of how galvanic corrosion works.

First, to have galvanic corrosion, you need:

- Dissimilar metals;

- They must be in contact with each other; and

- There must be an electrolyte.

When dissimilar metals come into contact with each other to form a “galvanic couple,” one metal acts as an anode and the other as a cathode. Just like they say, “In every relationship there’s give and take,” in the galvanic couple, the anode is the one giving and cathode is the one taking.

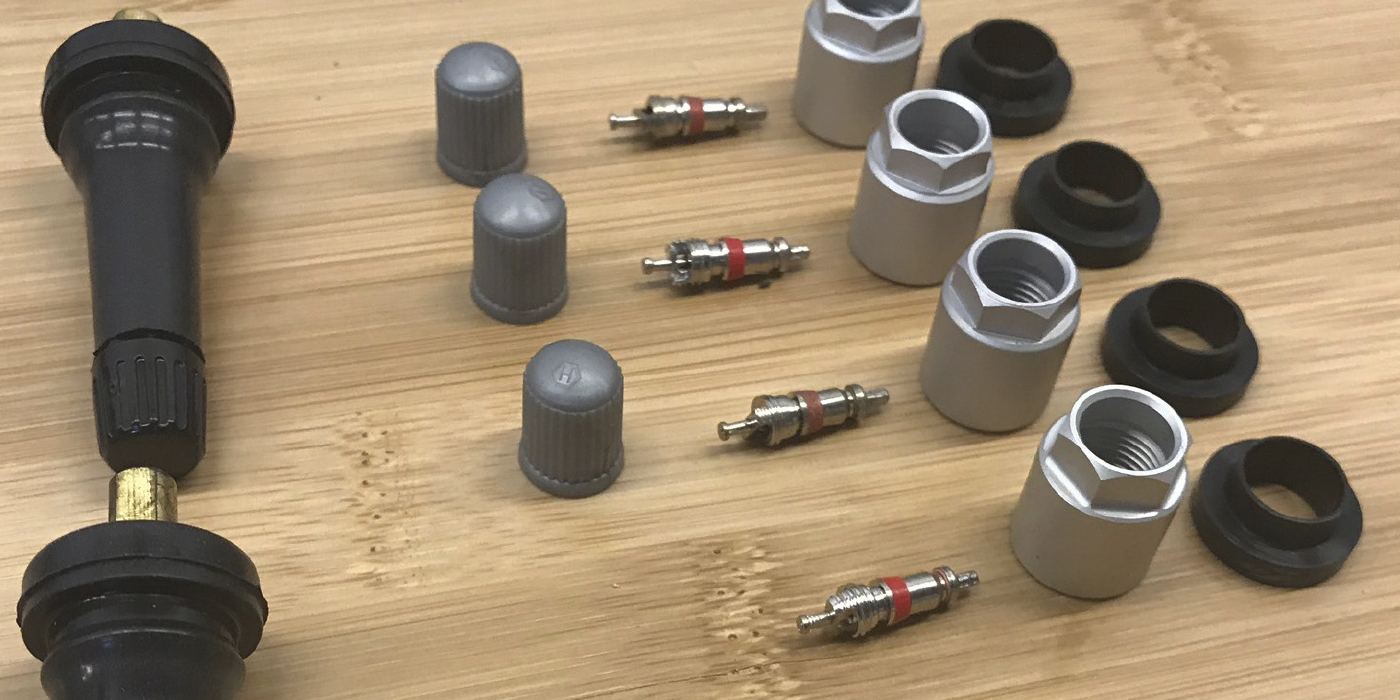

For TPMS sensor hardware, the aluminum valve stem serves as the anode and the brass valve core as the cathode. The electrolyte comes in the form of water (or any moisture, really). How galvanic corrosion works is the aluminum in the valve stem will dissolve into the electrolyte (moisture) and deposit onto the brass valve core. While the corrosion process is underway, the valve stem is losing its thickness and strength. Finally, it will fail, usually breaking where the valve core was in the most contact with the aluminum at the treads. This condition can be further exacerbated by the introduction of an additional cathode in the form of a steel valve cap causing the damage to the valve stem on the externally treaded portion, as well as on the inside.

Even though this is what ends up happening a lot of the time, it wasn’t designed that way. The TPMS sensor comes from the factory with its brass valve core coated in nickel, which acts as an insulator or barrier between the two dissimilar metals. The sensor also comes equipped with a valve cap fitted with a rubber seal to keep out the moisture. So, if the valve core is properly coated with an insulator like nickel, installed correctly with the proper amount of torque, and the correct valve cap is present and creating an effective seal, then there should be a very low incidence of corrosion. You shouldn’t have any problems with galvanic corrosion if the TPMS sensor assembly is serviced correctly. The problem, it is way too easy to do it wrong.

While the replaceable snap-in rubber valve used by several car manufacturers largely takes the worry out of servicing TPMS sensors, these are only found on a small number of the TPMS sensors in service. So, until all sensors start using a less corruptible system, follow these prevention basics to save yourself, or at least the next guy, some headache.

What’s the Mix Up?

Problems start arising when we mix and match valve cores and valve caps. That’s a big no-no. Unfortunately, there is still a lot of this happening. Like most things in life, we have to learn from our mistakes.

In the beginning, you probably weren’t told about the problems that come about when you mix and match hardware. And, as previously stated, it’s just too easy to mess it up. We have been using brass valve stems and brass valve cores forever. It has been the de facto standard for so long you probably have brass valve cores in your shop, or you will see them come into your shop at least once on any given day.

You do not want to use gold-colored brass valve cores in aluminum sensor assemblies. Only use the silver-colored, nickel-plated ones.

In fact, if you have any of those gold-colored ones in your shop today, go right now and throw them out. They sell valve cores in bulk, go buy a couple bags of the nickel-plated ones to keep on hand.

Installing the wrong valve core is by far the most common mistake, but you should also pay attention to the valve cap. Make sure you are installing a correct valve cap for the application. It should cover the important parts of the stem and include a seal, most likely in the form of a rubber O-ring, to keep the moisture out.

Five Steps to a Happier Future

Want to avoid future issues and prevent galvanic corrosion? Follow the manufacturer’s recommendations and service a TPMS sensor assembly the right way.

Here’s what you’ll need to do:

- Replace the retaining nut and seal.

- Replace the valve core with a new nickel-plated one.

- Properly torque the retaining nut and valve core to manufacturer’s specs. A valve core’s nickel coating can chip in its most vital area, exposing raw brass to the aluminum valve stem when over-torqued. If you don’t have a valve core driver that limits torque — get one. I suggest it being the only kind allowed in your shop.

- Properly inflate the tire with dry shop air or nitrogen.

- Install a new and proper valve cap with a seal to keep the moisture out.