UPDATE: The information about front rotor/disc replacement in the original article was for only the single wheel rear axle version. In the Ford service information, the torque specification is 22 lb.ft and then turned 90 degrees. The dual rear wheel version has a torque specification of 81 lb.ft. On both versions, Ford recommends new bolts when installing a new rotor/disc.

In 2014, Ford replaced the Econoline with a van that was designed for both Europe and North America called the Transit. This van is designed for fleets who will put on a lot of miles in a short amount of time. This means they will go through a lot of brake pads.

The Transit comes in 150, 250 and 350 sub-models. There is also an HD model with a dually rear axle.

Ordering Parts

Don’t confuse the Transit with the smaller Transit Connect. While there are four submodels, the rotor and calipers are the same.

The secret of Transit brake jobs is to match the friction material to the customer. Some pad manufacturers offer three options for the front and rear pads. The different formulations can suit fleets that use the Transit for city deliveries and others that carry heavy loads. Talk to your customer about how they use their vehicles.

Rotors

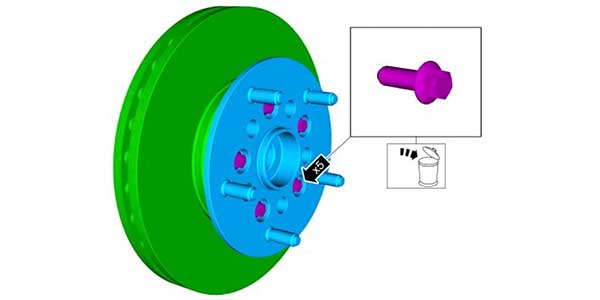

The front rotors are secured to the hub using bolts. These bolts can only be used once according to the service information. Tighten the bolts to 22 lb.ft and they need to be turned 90°.

In the rear, rotors have a torque spec of 81 lb.ft. Ford recommends replacing the bolts when the rotor is replaced.

These rotors have a considerable amount of material on the plates, using an on-the-car lathe can save you time removing the rotor from the hub.

Parking Brake Adjustment

1. Apply the brake pedal 10 times.

2. Make sure the parking brake control is in the released position.

3. Lift the vehicle with the transmission in neutral.

4. Remove the parking brake cable adjustment nut lock nut.

5. Tighten the parking brake cable adjustment nut. Torque : 71 lb.in.

6. Loosen the parking brake cable adjustment nut three turns.

7. Tighten the parking brake cable adjustment nut. Torque : 71 lb.in.

8. Fully apply the parking brake.

9. Release the parking brake.

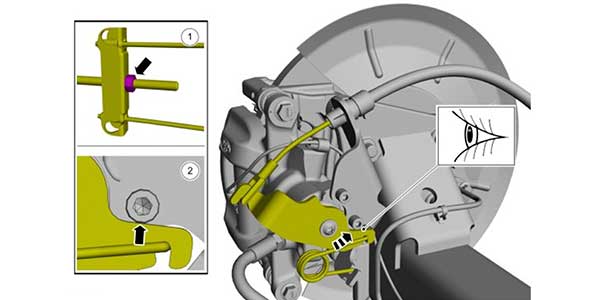

10. Loosen the parking brake cable adjustment nut until the brake caliper levers contact the brake caliper abutment on both sides.

NOTE: This step requires the aid of another technician.

11. Insert a 1.0 mm feeler gauge between the parking brake lever and the brake caliper abutment on both sides.

12. With the aid of another technician, tighten the parking brake cable adjustment nut until movement is observed on one of the parking brake levers.

13. Remove the feeler gauges.

14. Tighten the parking brake cable adjustment nut two complete turns.

Install the parking brake cable adjustment nut lock nut. Tighten the parking brake cable adjustment nut lock nut. Torque : 133 lb.in. n